Optical vacuum cold station for light microscope and electron microscope correlated imaging

A correlative imaging and vacuum cooling technology, which is applied in optics, optical components, and material analysis through optical means, can solve the problems of easy damage, easy pollution, and popularization of objective lens damage technology, so as to avoid the deformation of the carrier grid and solve the pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

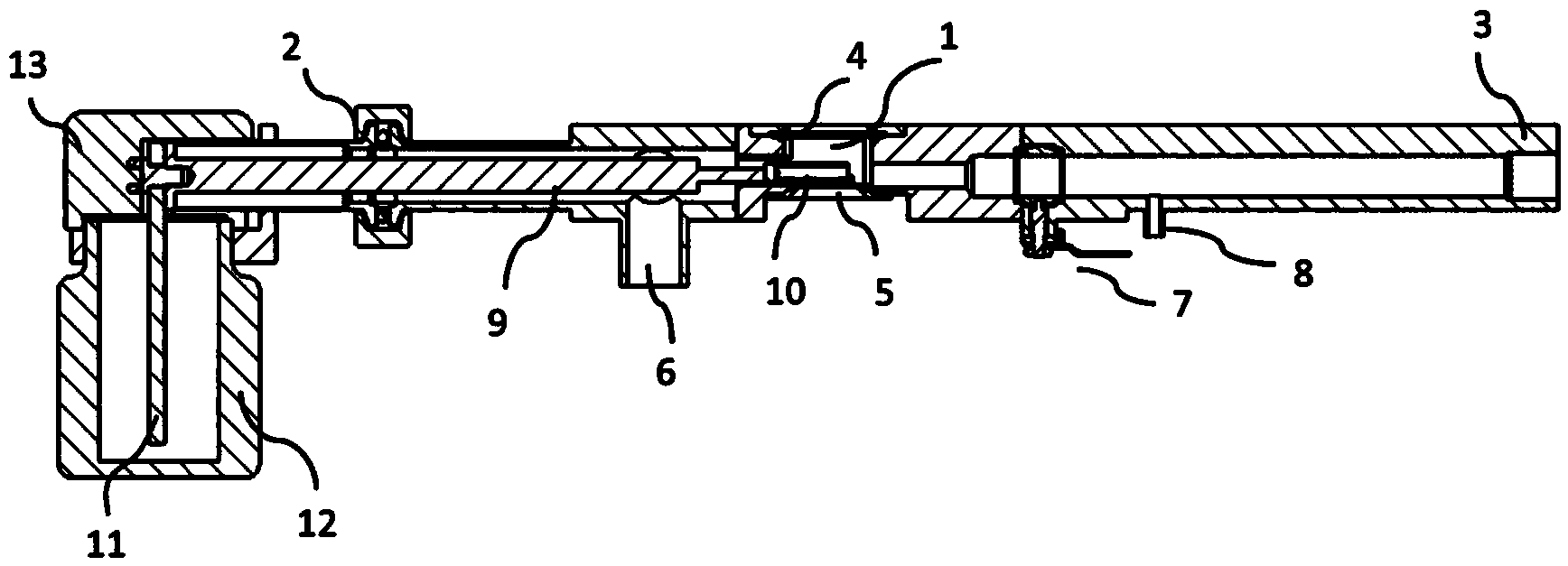

[0015] Such as figure 1 As shown, this embodiment includes a vacuum chamber 1 , one end of the vacuum chamber 1 is provided with an anti-pollution system adapter interface 2 , and the other end is provided with an electron microscope sample rod adapter interface 3 . An upper optical window 4 and a lower optical window 5 are arranged opposite to each other on the upper and lower walls of the vacuum chamber 1, and the upper and lower optical windows 4, 5 can be connected to the vacuum chamber 1 by bolts for easy disassembly. A vacuum system adapter interface 6 is provided on one side of the vacuum chamber 1 , which is used for connecting to a vacuum pump group for pumping vacuum for the vacuum chamber 1 . A vacuum valve 7 is arranged in the vacuum chamber 1 between the electron microscope sample rod adapter interface 3 and the upper and lower optical windows 4, 5, and a pre-vacuum is formed between the vacuum valve 7 and the electron microscope sample rod adapter interface 3 On...

Embodiment 2

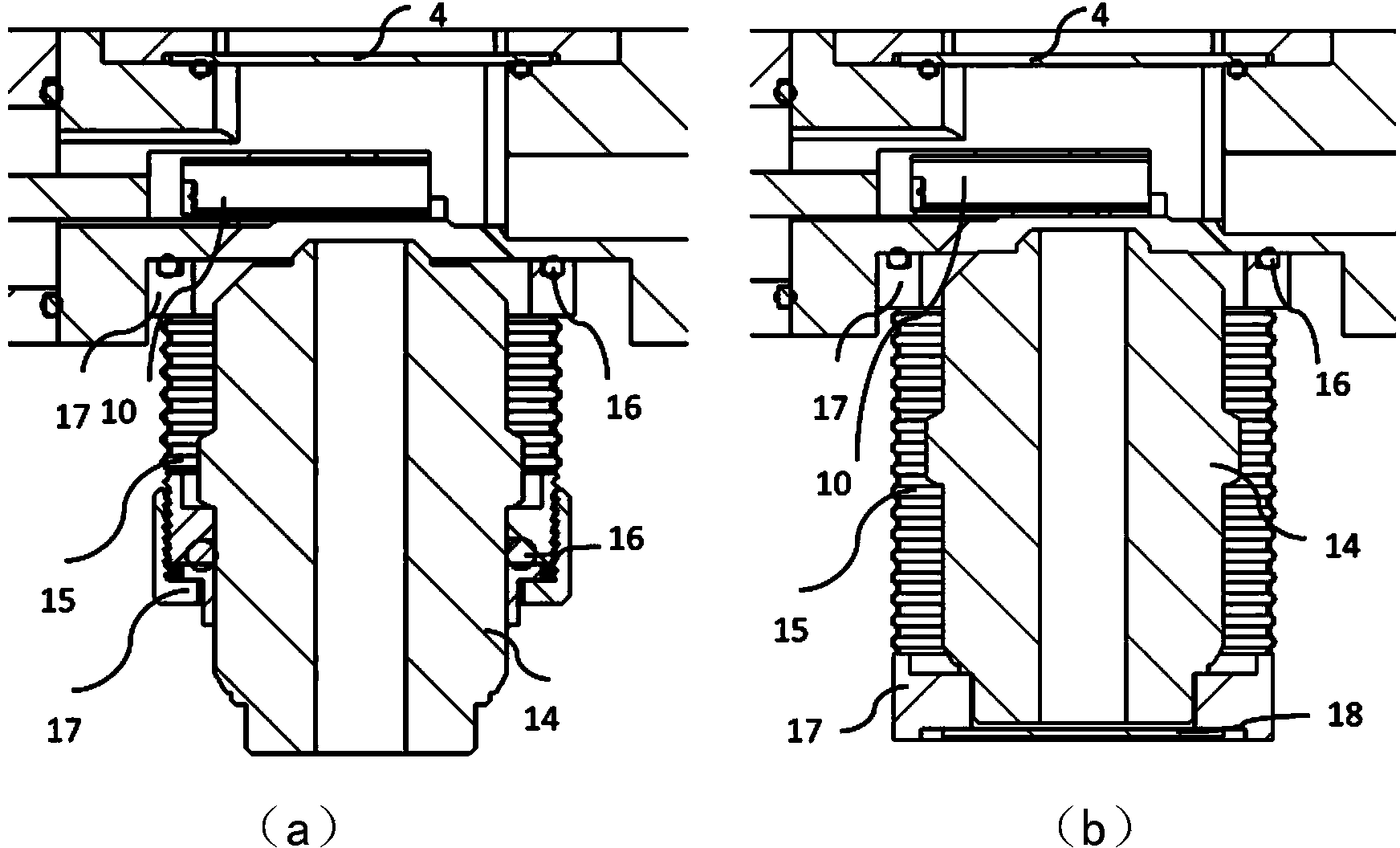

[0024] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes an anti-pollution system. The anti-pollution system includes a heat-conducting rod 9 that partially extends into the vacuum chamber 1 through the anti-pollution system adapter interface 2. The heat-conducting rod 9 is located at One end in the vacuum chamber 1 is connected to a metal cold box 10, the metal cold box 10 is opposite to the upper and lower optical windows 4, 5, and a pair of light-through holes are oppositely arranged on the upper and lower surfaces of the metal cold box 10 (in the figure not shown). One end of the heat conducting rod 9 outside the vacuum chamber 1 is connected to a heat conducting core 11 . The anti-pollution system also includes a Dewar tank 12. A liquid nitrogen chamber is formed inside the Dewar tank 12. The liquid nitrogen chamber is filled with liquid nitrogen and the tank mouth is covered by a liquid nitrogen chamber cover 13. The heat conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com