Refinery rich gas pretreatment method and dry gas and/or liquefied gas desulfurization method

A liquefied gas and pretreatment technology, which is applied in the field of desulfurization of rich gas, dry gas and liquefied petroleum gas in refineries, and can solve the problems of rapid catalyst deactivation and difficult handling of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

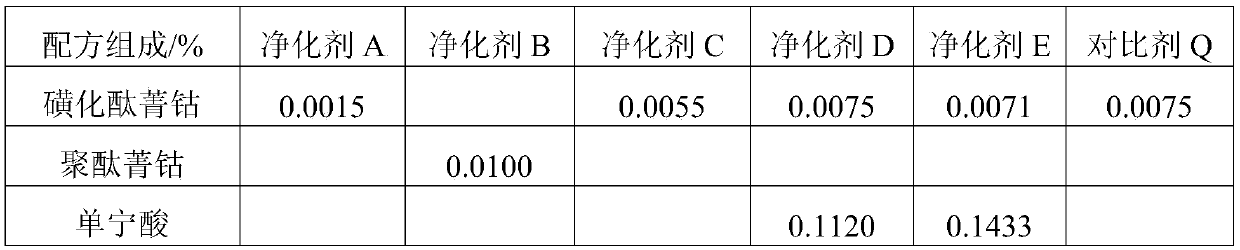

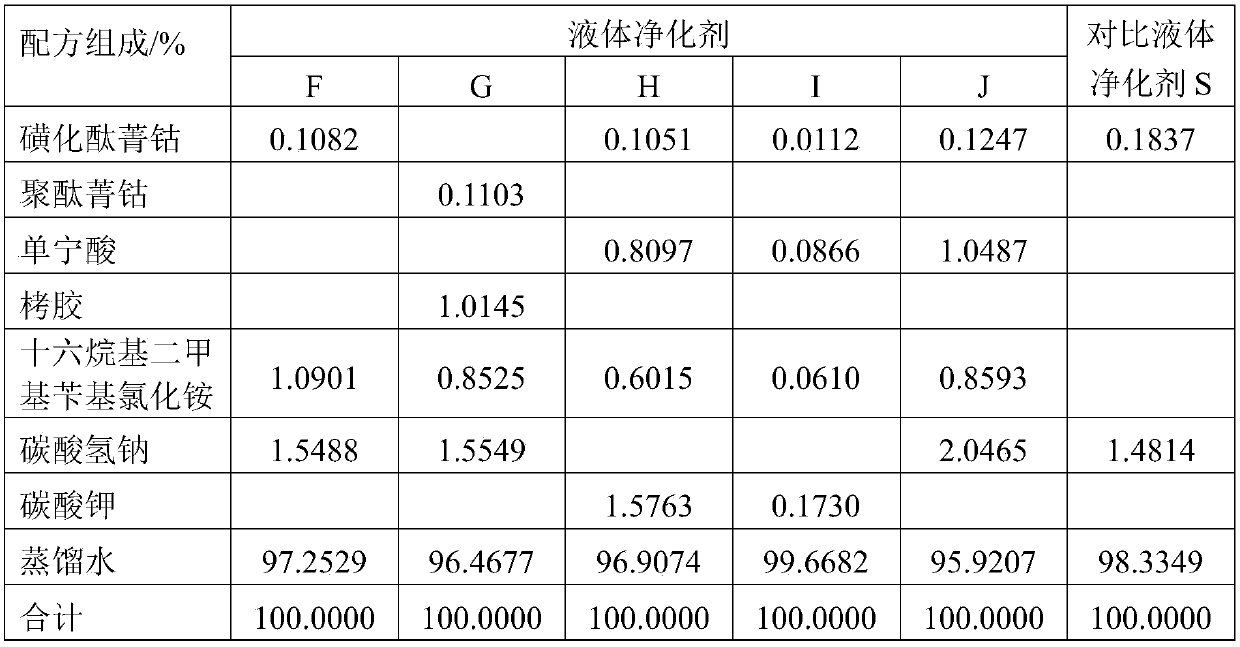

[0062] Embodiment 1 The properties of gas-rich raw materials in refinery and the preparation of purification agent

[0063] There are two types of refinery rich gas to be processed, one is refinery rich gas from catalytic cracking process of a Sinopec refinery, called refinery rich gas 1, and the other is refinery rich gas from delayed coking process of the same refinery Gas, known as refinery rich gas 2. The components and contents of these two refinery rich gases are shown in Table 1-1.

[0064] Table 1-1 Components and contents of refinery rich gas mg / m 3

[0065] components Refinery rich gas 1 Refinery Rich Gas 2 oxygen 0.0180v% 0.0252v% hydrogen sulfide 1129.3 >5% carbonyl sulfide 8.5 78.9 Methyl mercaptan 302.9 4163.2 ethanethiol 3.1 5.4 other sulfur 2.4 8.7 Organic sulfur content 316.9 4256.2 other components margin margin

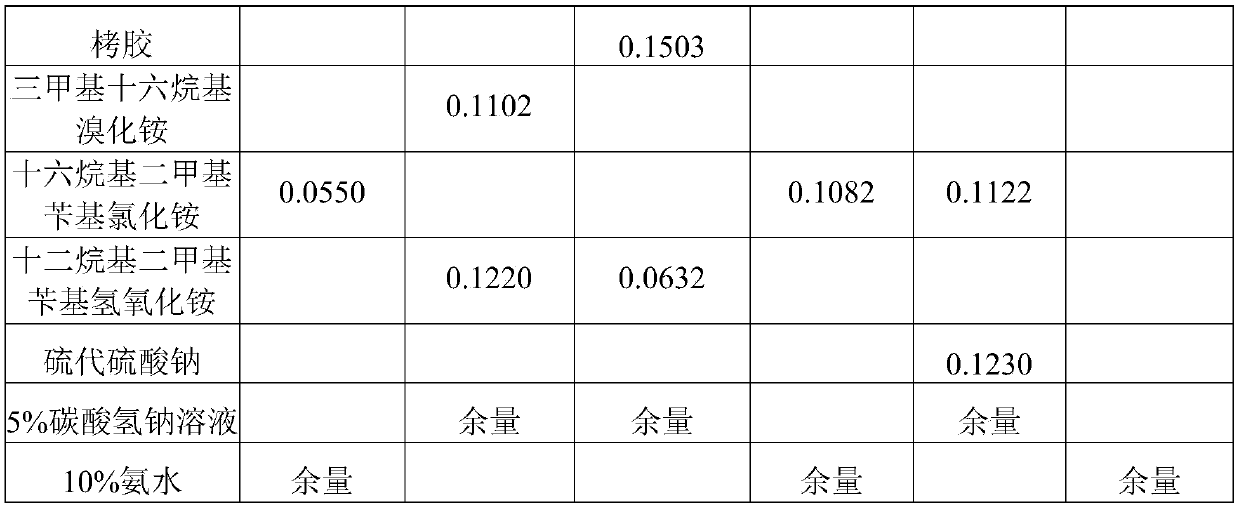

[0066] The preparation method of the liquid purifying agent comprises...

Embodiment 2

[0080] The evaluation method of embodiment 2 scavenger

[0081] For the liquid purifying agent, keep the temperature of the liquid purifying agent at 40°C, pass the enriched gas from the refinery through the distributor and the liquid purifying agent to realize gas-liquid mixing, and control the ventilation speed through the valve under the condition of airtight normal pressure, set The volumetric space velocity of the gas passing through the liquid purifier is 95h -1; For the solid purifying agent, the solid purifying agent is set on the reactor bed, the rich gas from the refinery is directly passed through the reactor bed, and the volume space velocity of the gas passing through the reactor bed is set to be 150h -1 . A compressor is used to compress the rich refinery gas after contacting with the purifying agent to 1.2MPa.

[0082] For the refinery-rich gas that has been in contact with the purifier, under 40°C, 1.2MPa and anaerobic conditions, it is fully contacted with s...

Embodiment 3

[0088] Example 3 Influence of Refinery Rich Gas Purification Treatment on Dry Gas Desulfurization Effect

[0089] Table 3-1 and Table 3-2 respectively list the properties of sulfides in the refined dry gas after the refinery rich gas 1 and refinery rich gas 2 are treated with the liquid purifier in Table 1-2, among which It includes the properties of sulfides in the refined dry gas directly prepared from the rich gas of the refinery without purification treatment, and the sulfides in the refined dry gas prepared from the rich gas of the refinery after being treated with the ordinary mercaptan oxidation catalyst Q.

[0090] Table 3-3 and Table 3-4 respectively list the sulfide properties of the refined liquefied gas obtained after the solid purification agent in Table 1-3 treats refinery rich gas 1 and refinery rich gas 2. It includes the sulfides in the refined dry gas directly prepared from the rich gas of the refinery without purification treatment, and the sulfides in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com