Quality improvement method of catalytic cracking gasoline

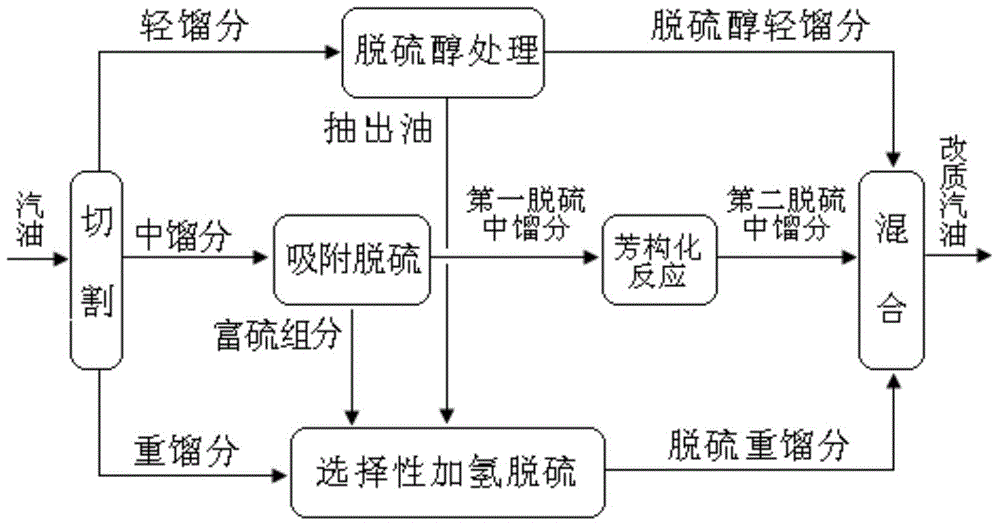

A technology of catalytic cracking gasoline and heavy gasoline, which is applied in the field of catalytic cracking gasoline upgrading, which can solve the problems of ineffective octane number recovery process, large proportion of hydroprocessing, and inability to effectively improve octane number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Preparation of desulfurization adsorbent

[0071] 1) Preparation of alkali-treated molecular sieve and activated carbon

[0072] After heating two 500mL NaOH solutions with a concentration of 0.3mol / L in a water bath to about 70°C, add 25g of ZSM-5 molecular sieve and 25g of activated carbon to them respectively, stir for about 200 minutes, and immediately cool the mixture in an ice bath. to normal temperature, filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 110°C for 4 hours to obtain alkali-treated ZSM- Type 5 molecular sieve and activated carbon treated with alkali;

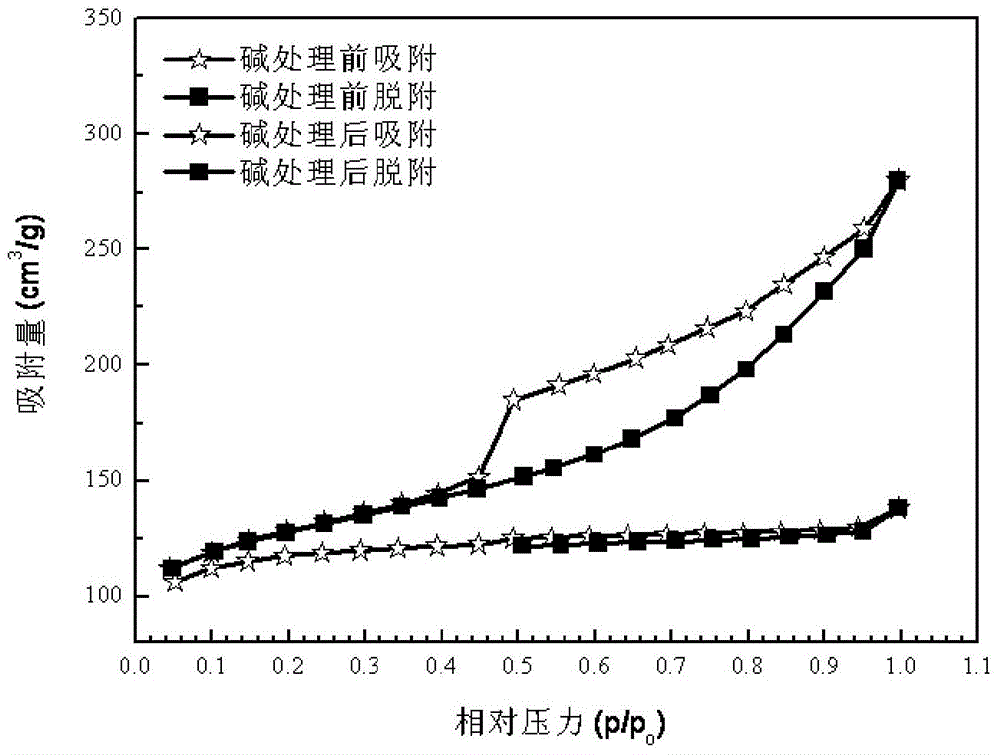

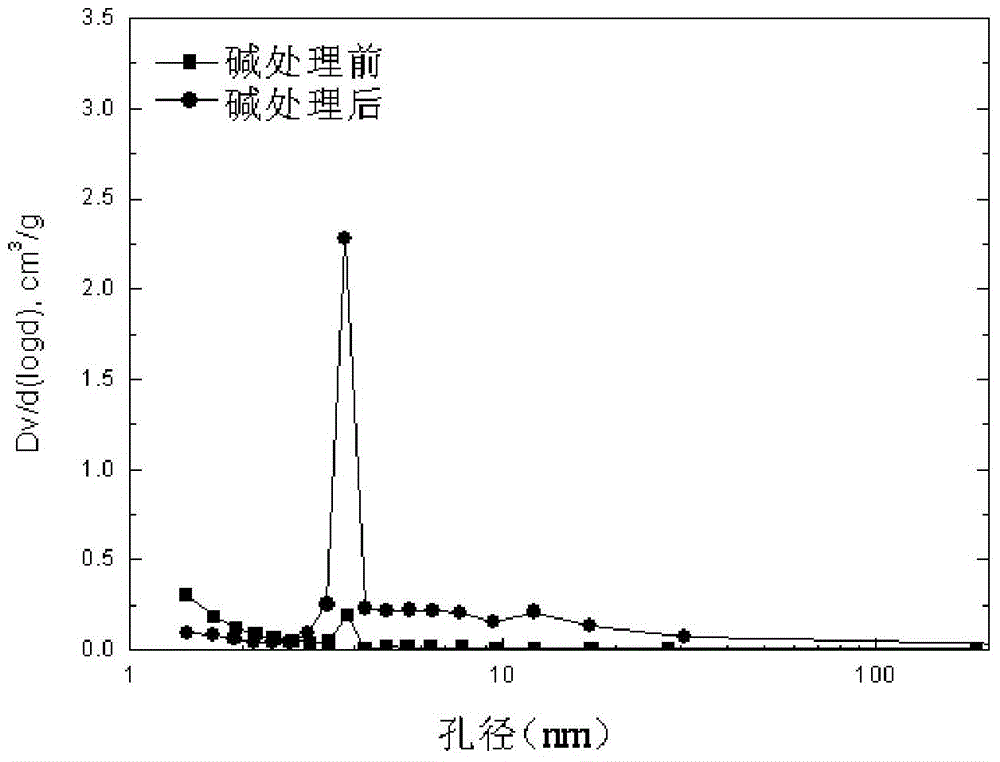

[0073] In addition, ASAP2000 automatic physical adsorption instrument was used to measure the specific surface area and pore size distribution of ZSM-5 molecular sieve and activated carbon, and the results are shown in Table 1.

[0074] Table 1 The specific surface area and pore s...

Embodiment 2

[0105] 1. Preparation of selective hydrodesulfurization catalyst

[0106] Prepare the selective hydrodesulfurization catalyst according to the method of Example 1, the difference is that the loading of Co on the carrier is controlled to be about 6%, the loading of Mo on the carrier is about 10%, and the Co and Mo loaded on the carrier The mass ratio is 0.6:1.

[0107] 2. Preparation of aromatization / hydroisomerization reaction catalyst

[0108] MCM-41 molecular sieve and alumina were mixed according to the mass ratio of 80:20 to prepare the second composite carrier, wherein the mass ratio of molecular sieve to alumina was 1:0.25.

[0109] Using ZnSO 4The solution impregnates the second composite carrier prepared above with an equal volume. After the impregnated material is washed with deionized water, it is dried at 110°C for 24 hours. Raise the temperature to 400°C, then raise the temperature to 450°C at a rate of 3°C / min, and bake at 450°C for 6 hours to prepare a catalys...

Embodiment 3

[0124] 1. Preparation of desulfurization adsorbent

[0125] 1) Preparation of alkali-treated molecular sieve and activated carbon

[0126] After raising the temperature of two 500mL NaOH solutions with a concentration of 0.2mol / L in a water bath to about 80°C, add 25g of Y-type molecular sieve and 25g of activated carbon to them respectively, stir for about 120 minutes, and immediately cool the mixture to room temperature in an ice bath , filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 120°C for 3 hours to obtain alkali-treated Y-type molecular sieve and The specific surface area and pore size distribution of alkali-treated activated carbon; Y-type molecular sieve and activated carbon are shown in Table 4.

[0127] Table 4 The specific surface area and pore size of Y-type molecular sieve and activated carbon

[0128]

[0129] 2) Preparation of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com