Desulfuration adsorbent

An adsorbent, ammonium metavanadate technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of low adsorbent specific surface area, low desulfurization agent selectivity, limited adsorption sulfur capacity, etc. The effect of operating cost, easy control and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

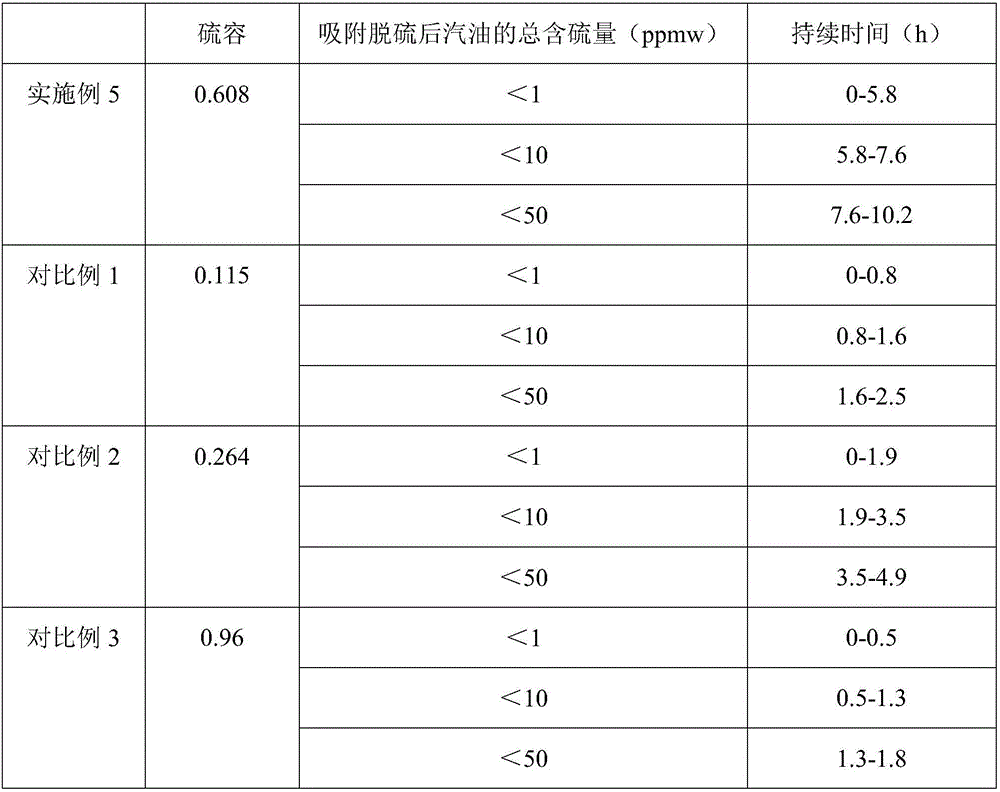

Embodiment 1

[0017] In the embodiment of the present invention, a desulfurization adsorbent is composed of the following raw materials in parts by weight: 33 parts of nano-attapulgite, 1 part of methyl ketone cyclohexyl ester, 7 parts of acrylic acid, and 11 parts of ammonium metavanadate.

[0018] Ammonium metavanadate was mixed with 6.1 times the mass of deionized water to prepare an ammonium metavanadate solution; acrylic acid was mixed with 2.7 times its mass of absolute ethanol to prepare an acrylic acid solution. Mix and grind nano-attapulgite and methyl ketone cyclohexyl ester, pass through a 120-mesh sieve, then add ammonium metavanadate solution, heat up to 72°C and seal and stir at this temperature for 2.1h, then add acrylic acid solution, heat up to 89°C and heated and stirred at this temperature for 15min, then ultrasonically treated at this temperature for 33min, with an ultrasonic power of 900W, then stirred at a temperature of 99°C until dry, and then calcined in a muffle fur...

Embodiment 2

[0020] In the embodiment of the present invention, a desulfurization adsorbent is composed of the following raw materials in parts by weight: 41 parts of nano-attapulgite, 5 parts of methyl ketone cyclohexyl ester, 15 parts of acrylic acid, and 19 parts of ammonium metavanadate.

[0021] Ammonium metavanadate was mixed with 6.1 times the mass of deionized water to prepare an ammonium metavanadate solution; acrylic acid was mixed with 2.7 times its mass of absolute ethanol to prepare an acrylic acid solution. Mix and grind nano-attapulgite and methyl ketone cyclohexyl ester, pass through a 120-mesh sieve, then add ammonium metavanadate solution, heat up to 72°C and seal and stir at this temperature for 2.1h, then add acrylic acid solution, heat up to 89°C and heated and stirred at this temperature for 15 minutes, then ultrasonically treated at this temperature for 33 minutes, with an ultrasonic power of 900W, then stirred at a temperature of 101°C until dry, and then calcined in...

Embodiment 3

[0023] In the embodiment of the present invention, a desulfurization adsorbent is composed of the following raw materials in parts by weight: 35 parts of nano-attapulgite, 2 parts of methyl ketone cyclohexyl ester, 9 parts of acrylic acid, and 13 parts of ammonium metavanadate.

[0024] Ammonium metavanadate was mixed with 6.1 times the mass of deionized water to prepare an ammonium metavanadate solution; acrylic acid was mixed with 2.7 times its mass of absolute ethanol to prepare an acrylic acid solution. Mix and grind nano-attapulgite and methyl ketone cyclohexyl ester, pass through a 120-mesh sieve, then add ammonium metavanadate solution, heat up to 72°C and seal and stir at this temperature for 2.1h, then add acrylic acid solution, heat up to 89°C and heated and stirred at this temperature for 15 minutes, then ultrasonically treated at this temperature for 33 minutes, with an ultrasonic power of 900W, and then stirred at a temperature of 100°C until dry, and then calcined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com