A combination process for deep desulfurization and refining of liquefied petroleum gas

A technology for deep desulfurization of liquefied petroleum gas, applied in the petroleum industry, gas mixture processing, gas fuel, etc., can solve the problems of reducing sulfur content, unreached, alkali residue discharge, etc., and achieve high desulfurization depth and no waste alkali residue Emissions, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

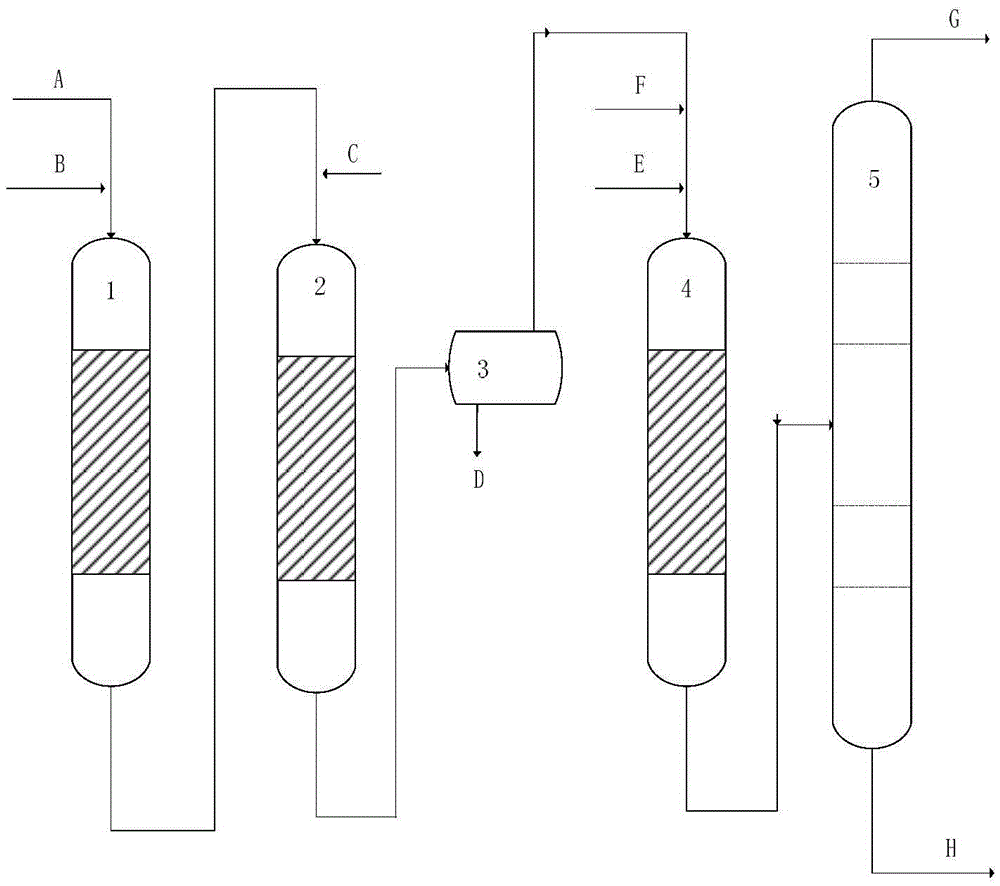

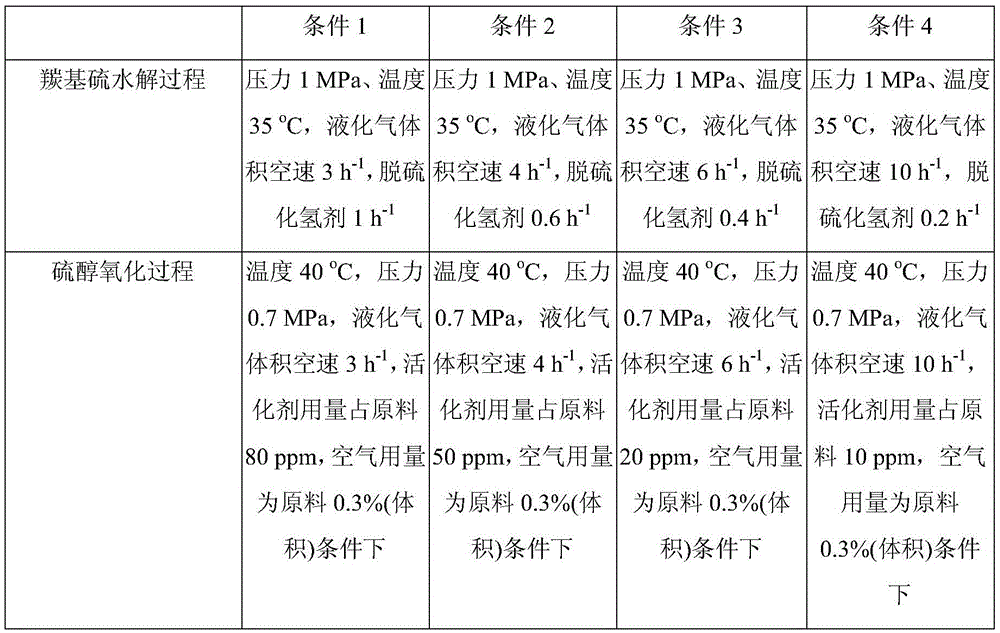

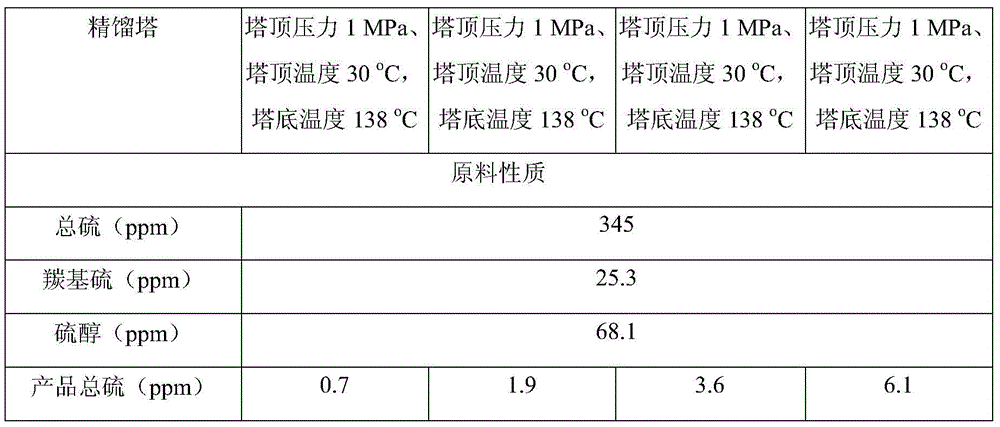

[0031] Liquefied gas raw material A is mixed with dehydrogen sulfide agent B and then enters fixed bed reactor 1 filled with carbonyl sulfide hydrolysis catalyst, at a pressure of 0.5-3.0MPa, a temperature of 20-50°C, and a volume space velocity of liquefied gas of 2-10h -1 , hydrogen sulfide removal agent 0.2-1.0h -1 Under these conditions, the carbonyl sulfide hydrolysis reaction and the hydrogen sulfide removal process are simultaneously carried out, and the liquefied gas after the reaction enters the oil separation tank 2 to separate the liquefied gas from the desulfurizing agent, and the desulfurizing agent can be recycled to a certain extent and then regenerated; The liquefied gas enters the water washing tower to further remove the carried desulfurizer, and the liquefied gas enters the oil-water separation tank 4 for further dehydration after water washing. After washing with water, the liquefied gas is mixed with a certain amount of air and a sweetening activator, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com