Adsorbent for deep desulfurization of refined benzene and preparation method thereof

A deep desulfurization and adsorbent technology, applied in the direction of adsorption purification/separation, chemical instruments and methods, and other chemical processes, can solve the problems of high temperature and pressure requirements, increased reaction difficulty and investment costs, etc., to achieve strong adsorption, The effect of large sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

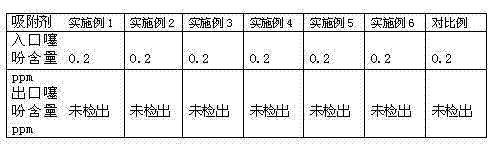

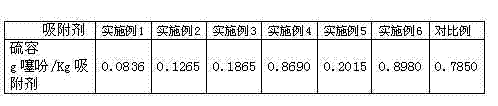

Examples

Embodiment 1

[0025] Take 200g of the г-phase spherical alumina carrier with a particle size of 1.5-3mm and a bulk density of 0.65g / ml produced by the rolling granulation method produced in China, and put it in 400ml of chloropalladium acid solution (palladium chloride solution) with a concentration of 0.0141mol / L. Soak in a solution prepared in dilute hydrochloric acid) at room temperature, filter out the adsorbent after 200 minutes and drain it, wash it with flowing deionized water until chloride ions cannot be detected with 1% silver nitrate solution in the washing water, and then absorb the adsorbent The agent is first put into an oven for drying at 60-150°C, then placed in a high-temperature furnace and roasted in an atmosphere at 300-600°C for 2-5 hours, and then cooled to room temperature to obtain the required adsorbent. The weight content of the precious metal palladium is 0.3%.

Embodiment 2

[0027] Take 200g of the г-phase spherical alumina carrier with a particle size of 1.5-3mm and a bulk density of 0.65g / ml produced by the rolling granulation method produced in China, and put it in 400ml of chloropalladium acid with a temperature of 40-95°C and a concentration of 0.0470mol / L Soak in solution (a solution made of palladium chloride dissolved in dilute hydrochloric acid), filter out the adsorbent after 30 minutes and drain it, wash it with flowing deionized water until no chloride ion can be detected with 1% silver nitrate solution in the washing water So far, put the adsorbent in an oven for drying at 60-150°C, then put it in a high-temperature furnace and roast it in an atmosphere at 300-600°C for 2-5 hours, and then cool it to room temperature to obtain the adsorbent. The weight content of precious metal palladium is 1%.

Embodiment 3

[0029] Take 200g of domestically produced г-phase columnar alumina carrier with a diameter of 3mm and a length of 3-8mm and a bulk density of 0.62g / ml into a 1000ml beaker, and pour 100ml of lanthanum nitrate aqueous solution with a concentration of 0.1440mol / L and a temperature of room temperature into the above oxidation Aluminum carrier, and stir it with a glass rod to make it absorb evenly, put the above-mentioned uniformly absorbed alumina carrier in an oven for drying at 60~150°C, and then put it in a high temperature furnace at 300~950°C for 2~5 hours in an air atmosphere After cooling to room temperature, put it away, and the weight content of lanthanum on the alumina is about 5%.

[0030] Soak the above-mentioned alumina spheres in 400ml of palladium nitrate aqueous solution (solution made by dissolving palladium nitrate in water) with a concentration of 0.0470mol / L at room temperature, filter out the adsorbent after 200 minutes and drain it, and use a flowing Wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com