Novel globular active carbon and use in desulfuration field

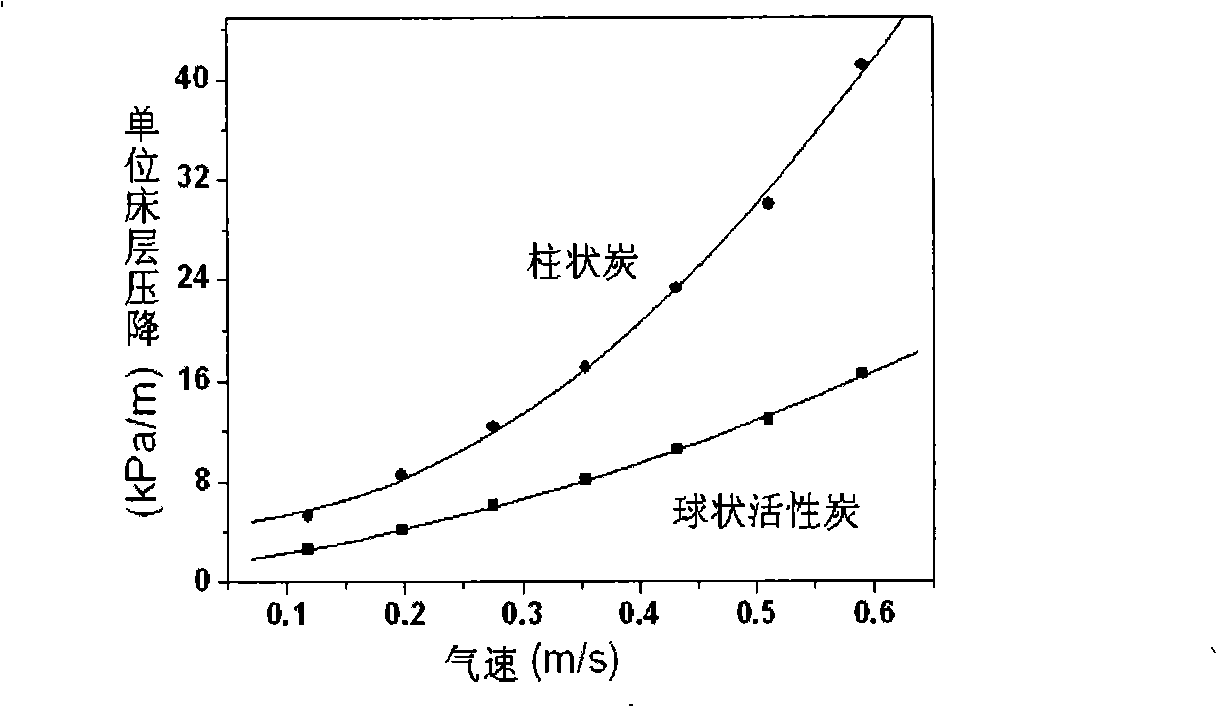

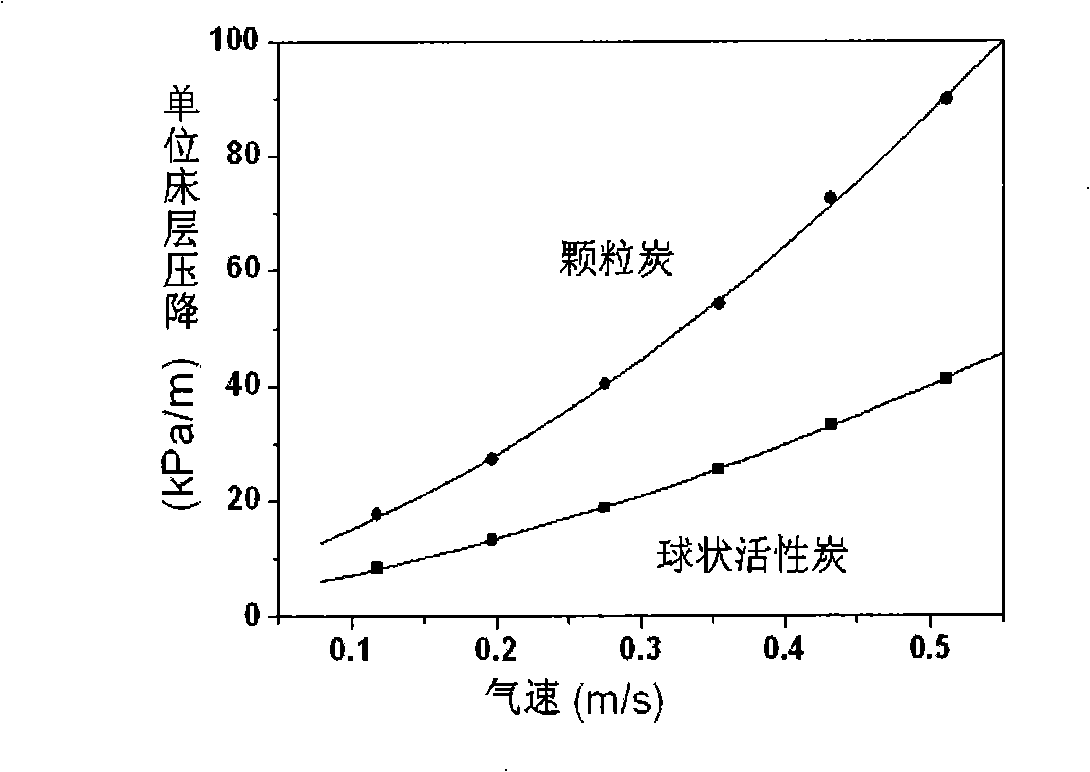

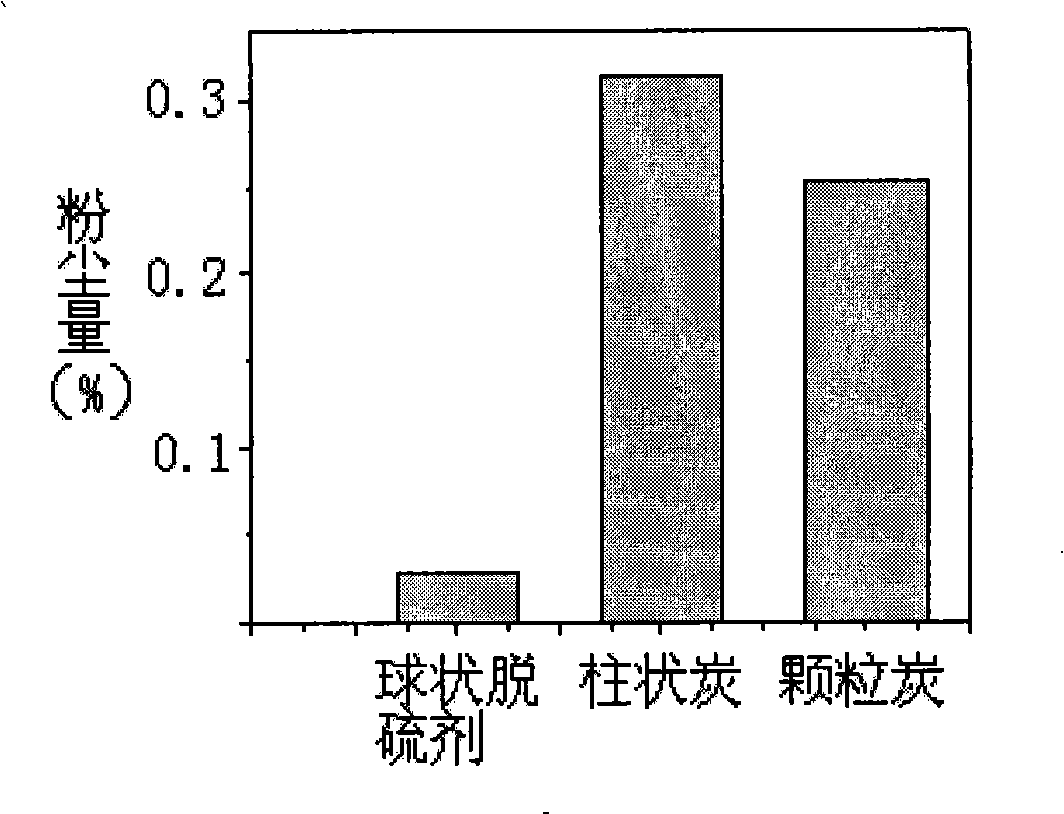

A technology of activated carbon and spherical shape, which is applied in the new spherical activated carbon and its application in the field of desulfurization. It can solve the problems of high resistance and small sulfur capacity of fixed bed, and achieve the effect of regular structure, small gas pressure drop and uniform appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mix 10 g of pitch-based spherical activated carbon (PSAC-220) with 8% Na 2 CO 3 The solution was impregnated with an equal volume, and dried at 120° C. for 24 hours to obtain the novel spherical activated carbon of the present invention.

[0041] With novel spherical activated carbon of the present invention as desulfurizer, at normal pressure, temperature is 30 ℃, relative humidity is 90%, H 2 The desulfurization performance was characterized under the condition that the S inlet concentration was 1500ppm and the oxygen content was 1%. When the breakthrough concentration was 1ppm, the test results showed that the breakthrough sulfur capacity of the new spherical activated carbon desulfurizer was 62%.

Embodiment 2

[0043] The spherical activated carbon of the present invention was prepared by impregnating 10 g of phenolic resin-based spherical activated carbon with KOH solution with a mass concentration of 5% in equal volume, and drying at 120° C. for 24 hours.

[0044] The new spherical activated carbon of the present invention is used as a desulfurizer, and the desulfurization performance is characterized under the conditions of normal pressure, temperature of 25°C, relative humidity of 80%, H2S concentration of 1500ppm, and oxygen content of 1%. When the breakthrough concentration is 1ppm , The test results show that the breakthrough sulfur capacity of the new spherical activated carbon is 54%.

Embodiment 3

[0046] At normal pressure, temperature is 30°C, relative humidity is 90%, H in raw gas 2 S content is 1000ppm, and oxygen content is under the condition of 1%, the novel spherical activated carbon desulfurizer of embodiment 1, common impregnated active carbon, high sulfur capacity impregnated activated carbon dry desulfurizer (patent No. CN1088387C), U.S. Westvaco active carbon carry out performance comparison , the results are shown in Table 1. As can be seen from Table 1, when the breakthrough concentration is 1 ppm, the breakthrough sulfur capacity of the new spherical activated carbon of the present invention as a desulfurizer is the largest, which can reach 62%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com