Single crystal nickel-cobalt-manganese lithium anode material, precursor and preparation methods for single crystal nickel-cobalt-manganese lithium anode material and precursor

A technology of nickel-cobalt-lithium-manganese-manganese-oxide and positive-electrode materials, which is applied in the field of precursors and their preparation, single-crystal doped multi-element nickel-cobalt-lithium-manganese-manganese-oxide positive-electrode materials, and can solve the effects of unfavorable positive-electrode materials on firing, morphology, and density, etc. problem, to achieve the effect that is beneficial to the formation of single crystal, small loose packing and tap density, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

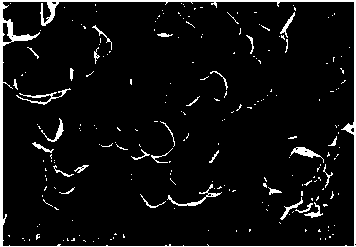

[0045] Prepare 1.5mol / L nickel-cobalt-manganese sulfate mixed solution (molar ratio Ni:Co:Mn=50:20:30), 3mol / L NaOH solution, 3mol / L ammonia water, 10g / L PEG1000 dispersant aqueous solution , put the above solutions into the reaction kettle in parallel flow, keep the reaction temperature at 50°C, and the reaction pH value at 12.0. Under nitrogen protection atmosphere, wash, dry at 120°C, and sieve to obtain a loose morphology The small particle nickel cobalt manganese hydroxide precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 . Such as figure 1 As shown, the nickel-cobalt-manganese hydroxide is densely stacked in small plates, with low density and large specific surface area; test result D 50 5.5 μm, D max is 14.47μm, and the specific surface area is 12.92m 2 / g, bulk density AD is 0.86g / cm 3 , the tap density TD is 1.65 g / cm 3 .

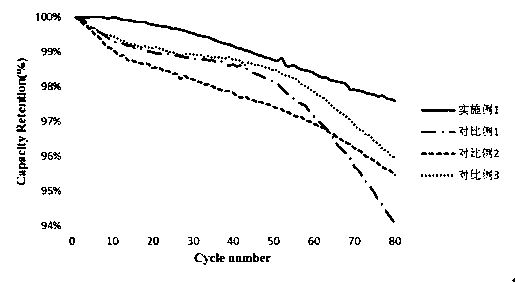

[0046] The obtained nickel-cobalt lithium manganese oxide cathode material precursor, lithium carbonate, strontium carbonate, and magnesium oxide we...

Embodiment 2

[0048] Prepare 1.8mol / L nickel-cobalt nitrate mixed solution (molar ratio Ni:Co:Mn=63:17:20), 5mol / L NaOH solution, 5mol / L ammonia water, 5g / L polyvinyl alcohol dispersion The above-mentioned solutions are passed into the reaction kettle in parallel flow, the reaction temperature is set at 55°C, the pH value is 12.5, and the precipitation is carried out under the protection atmosphere of argon, washed, dried at 115°C, and sieved. Obtain a loose morphology of small particles of nickel cobalt lithium manganate cathode material precursor Ni 0.63 co 0.17 mn 0.2 (OH) 2 ;Such as image 3 As shown, the nickel-cobalt-manganese hydroxide is densely stacked in small plates, similar in appearance to Example 1, and slightly smaller in particle size; the D of the nickel-cobalt-manganese hydroxide is tested. 50 4.26μm, D max is 12.19μm, and the specific surface area is 18.75m 2 / g, bulk density AD is 0.82g / cm 3 , the tap density TD is 1.63 g / cm 3 .

[0049] The resulting nickel cob...

Embodiment 3

[0051] Prepare 2mol / L nickel-cobalt-manganese sulfate mixed solution (molar ratio Ni:Co:Mn=82:9:9), 8mol / L NaOH solution, 8mol / L ammonia water, 20g / L polyglycerol dispersant aqueous solution , the above-mentioned several solutions are passed into the reaction kettle in a co-current manner, the reaction temperature is set at 60°C, the pH value is 12.8, and the precipitation is carried out under a nitrogen protection atmosphere, washed, dried at 115°C, and sieved to obtain a loose form Small particle nickel cobalt lithium manganese oxide cathode material precursor Ni 0.82 co 0.09 mn 0.09 (OH) 2 . Such as Figure 5 As shown, the nickel-cobalt-manganese hydroxide is densely stacked in small pieces, and the particles are smaller, similar in appearance to Example 1, D 50 3.98 μm, D max is 9.93μm, and the specific surface area is 21.28m 2 / g, bulk density AD is 0.80g / cm 3 , the tap density TD is 1.51 g / cm 3 .

[0052] The obtained nickel cobalt manganese hydroxide precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com