Foaming type inorganic heat insulation plate, preparation method thereof and heat insulation layer thereof

A technology of inorganic heat preservation and heat insulation boards, applied in heat preservation, ceramic molding machines, ceramic products, etc., can solve the problems that building materials do not meet the requirements of energy saving, the application range is limited, and the construction steps are complicated, so as to achieve good economy, The effect of reducing human factors, reducing thermal conductivity and bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

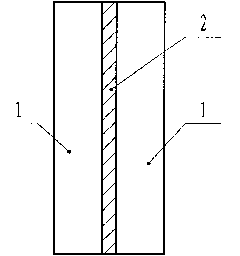

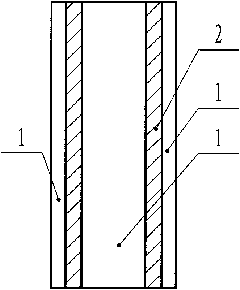

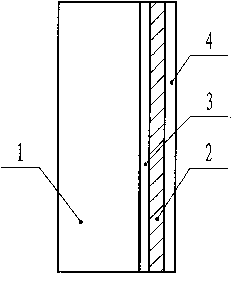

[0032] The foamed inorganic thermal insulation board includes: the main body of the heat insulation board 1 and the glass fiber mesh cloth 2, and the raw materials of the main body of the heat insulation board 1 are configured according to the following parts by weight:

[0033] 10-55 parts of composite lightweight bone admixture, 10-50 parts of cement, 5-30 parts of lime, 3-20 parts of gypsum, 1-10 parts of silica fume, 10-55 parts of water glass, and use foaming agent to pass through the foaming machine The density obtained by foaming is 15~40kg / m 3 10-60 parts of the foam body; the raw materials of the heat insulation board main body 1 also include: 3-20 parts of fly ash, 0.1-3 parts of rubber powder, 0.05-2 parts of cellulose ether, and 0.01-2 parts of sodium sulfate , 0.1-3 parts of water reducing agent, 0.1-2 parts of water-repellent agent, 0.01-1 part of polypropylene fiber, 1-10 parts of bone glue, 5-30 parts of emulsion, 4-12 parts of waste slag, 1-45 parts of water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com