Cold aggregate batching treatment method and device for continuous bituminous concrete mixing equipment

A kind of asphalt concrete and mixing equipment technology, which is applied in the direction of clay preparation device, mixing operation control device, and sales raw material supply device, etc., which can solve the problems of widely different requirements and no screening machine, etc., and achieve the effect of good quality and reasonable gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

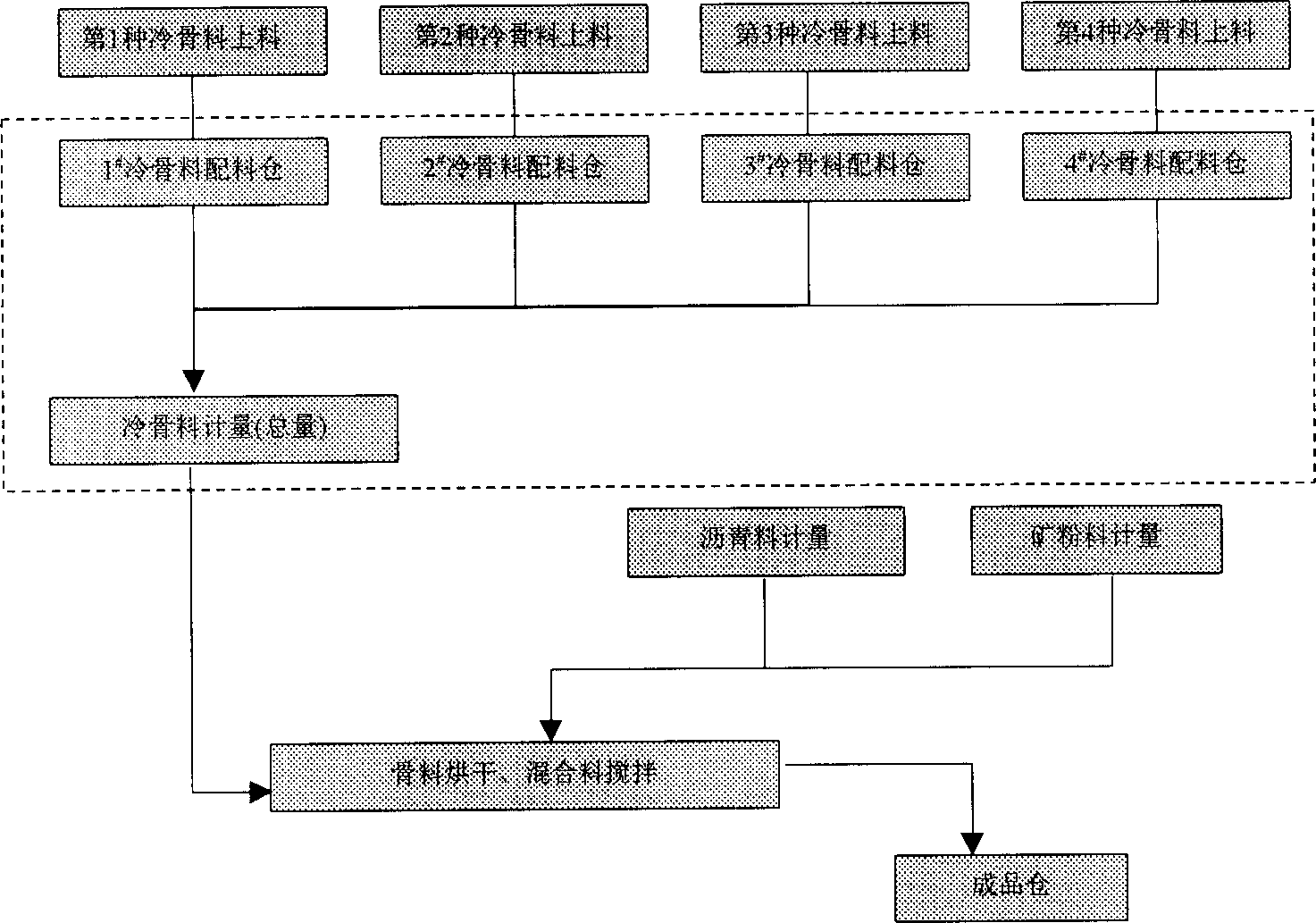

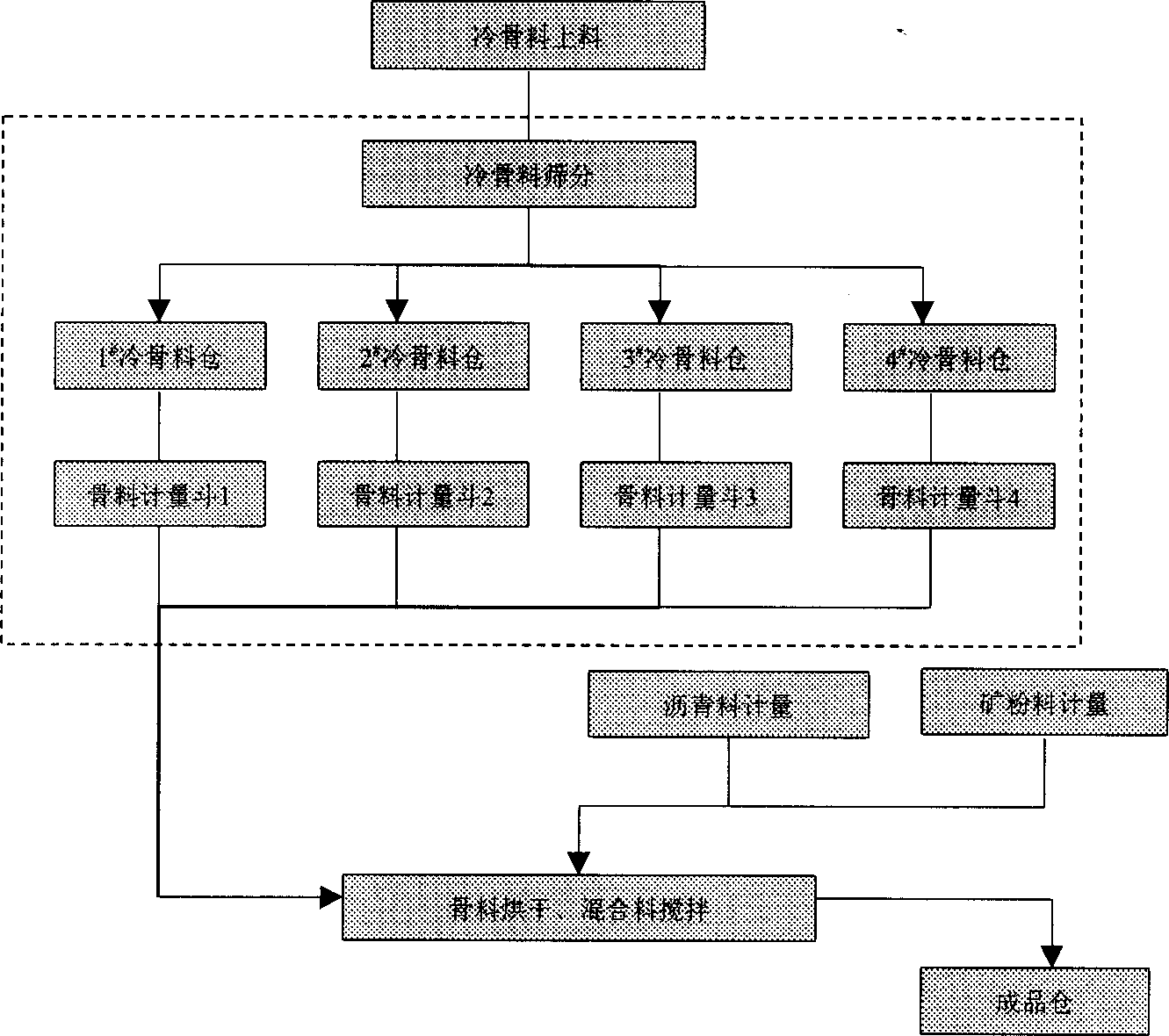

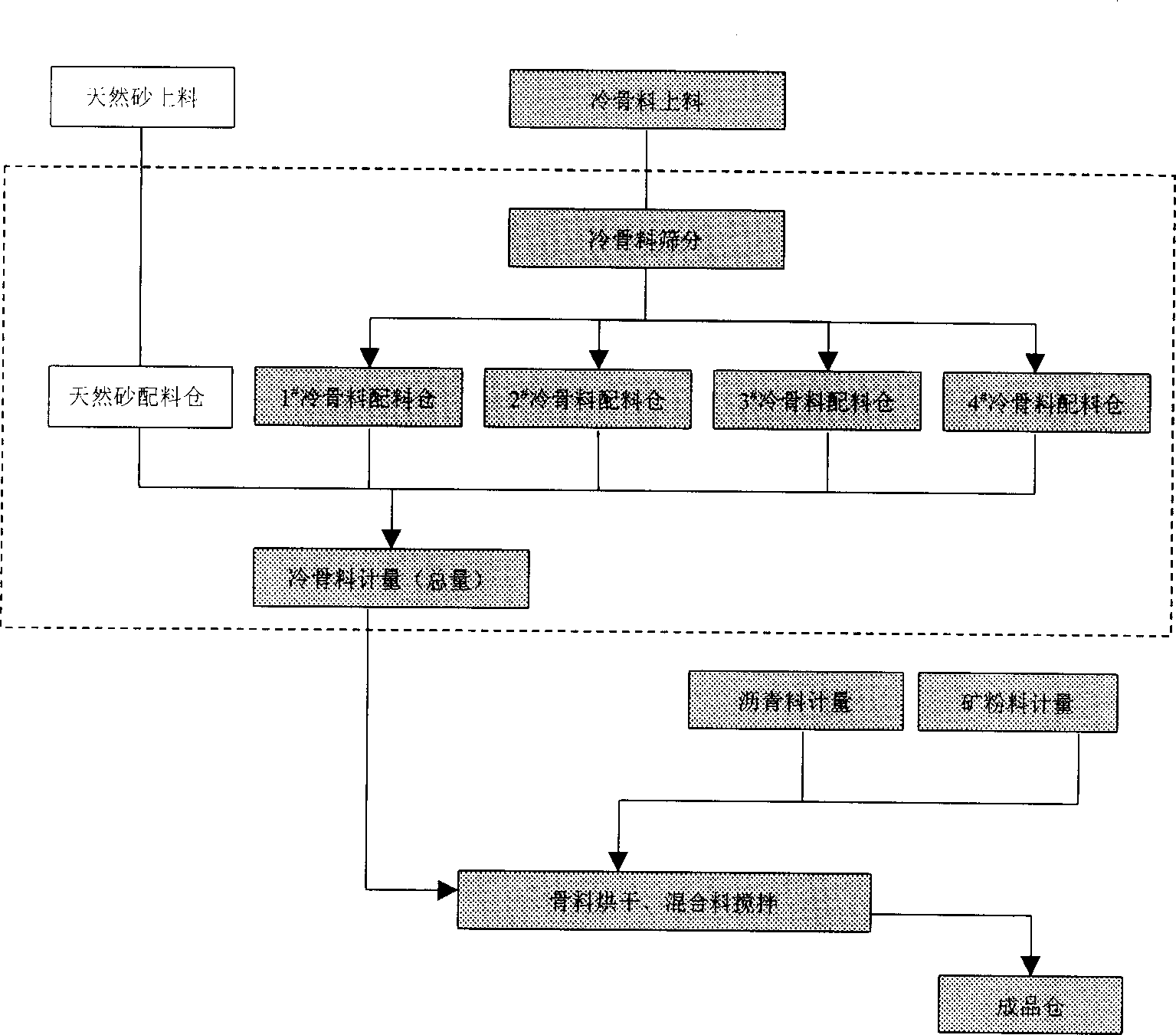

[0016] Such as figure 1 As shown, the process flow of the cold aggregate batching system of the existing widely used continuous asphalt concrete mixing plant is inside the dotted line box. Aggregate is loaded from the well-graded stockpile area to several "cold aggregate batching bins", and batched through each batching device (assuming that 4 specifications of aggregates are used for batching). The metering method of the batching process Usually, the "volume method" is adopted, that is, the cold aggregates of four specifications are sent to a collection belt conveyor after batching, and then the total weight of several kinds of aggregates flowing per unit time is measured by a "belt electronic scale". The detection is used as the basis for proportion control in the future asphalt metering and mineral powder metering. figure 1 The batching process is: multiple cold aggregate batching bins-continuous measurement of cold aggregate (to measure the total amount of aggregate). De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com