Heat-insulation, fireproof and explosion-proof battery pack

A technology for battery packs and explosion-proof holes, which is applied to battery pack parts, battery covers/end covers, battery boxes/coats, etc., and can solve battery pack smoke and fire, explosion, combustion, electric vehicle combustion accidents, and combustible fires Combustion and other problems to achieve the effect of reducing the size of the fire and ensuring safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

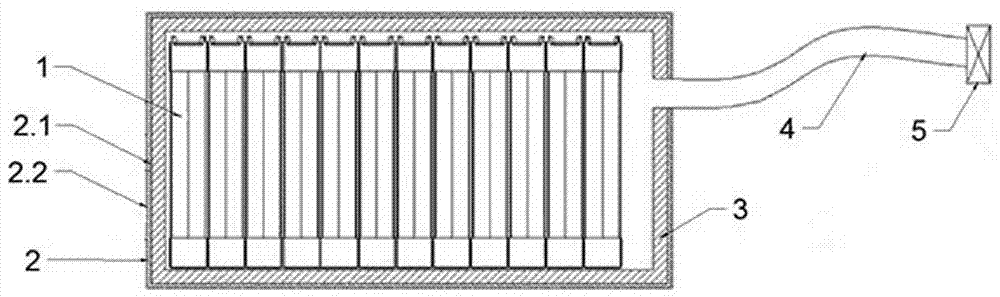

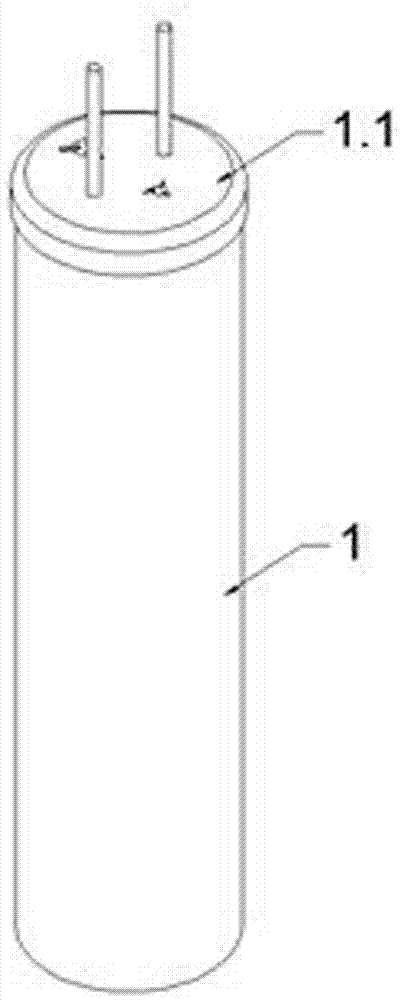

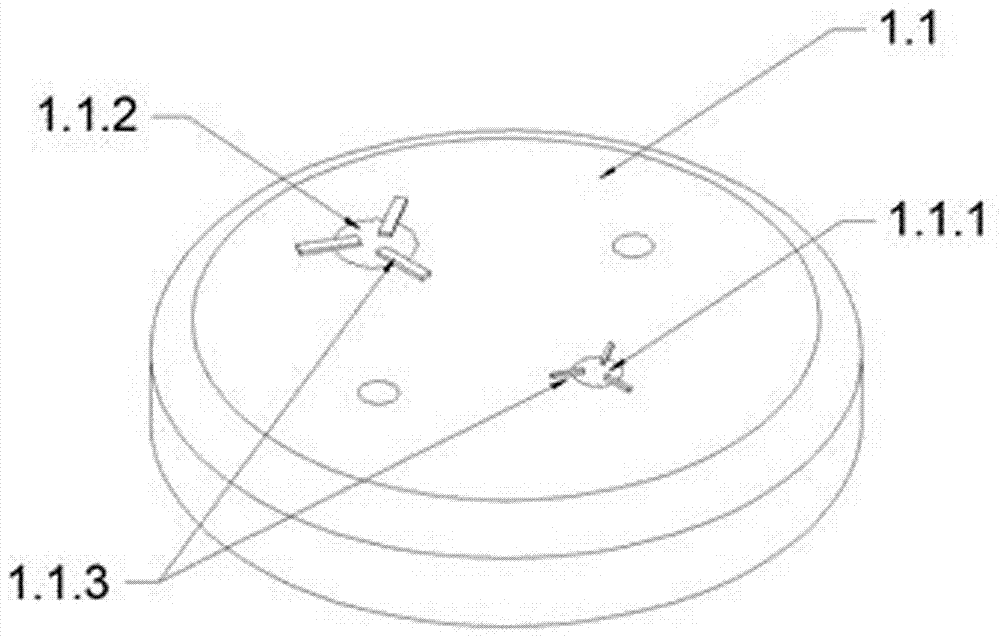

[0028] Such as Figure 1-2 As shown, a heat-insulated, fire-proof and explosion-proof battery pack includes a plurality of lithium-ion battery cells 1, and the battery cells 1 are first connected in parallel and then connected in series to form a lithium-ion battery pack. The battery pack is placed in a box body 2, and the box body 2 is a packing box for the battery pack. In order to improve the mechanical strength of the box body 2, the box body 2 is designed as a double-layer protective structure, that is, it includes a box inner layer 2.1 and a box outer layer 2.2, and the box inner layer 2.1 and the box body The outer layer 2.2 is fixed by epoxy bonding. The selection of the type of the adhesive is conveniently based on its bonding firmness, and on the other hand its flame retardant perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com