Coal gangue-pulverized fuel ash-silica sand tailing system all-waste-residue foam ceramic and preparation method thereof

A technology of fly ash and coal gangue, which is applied in the field of coal gangue-fly ash-silica sand tailings system full waste slag foam ceramics and its preparation, can solve the problems of low utilization rate and achieve the effect of high waste slag utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

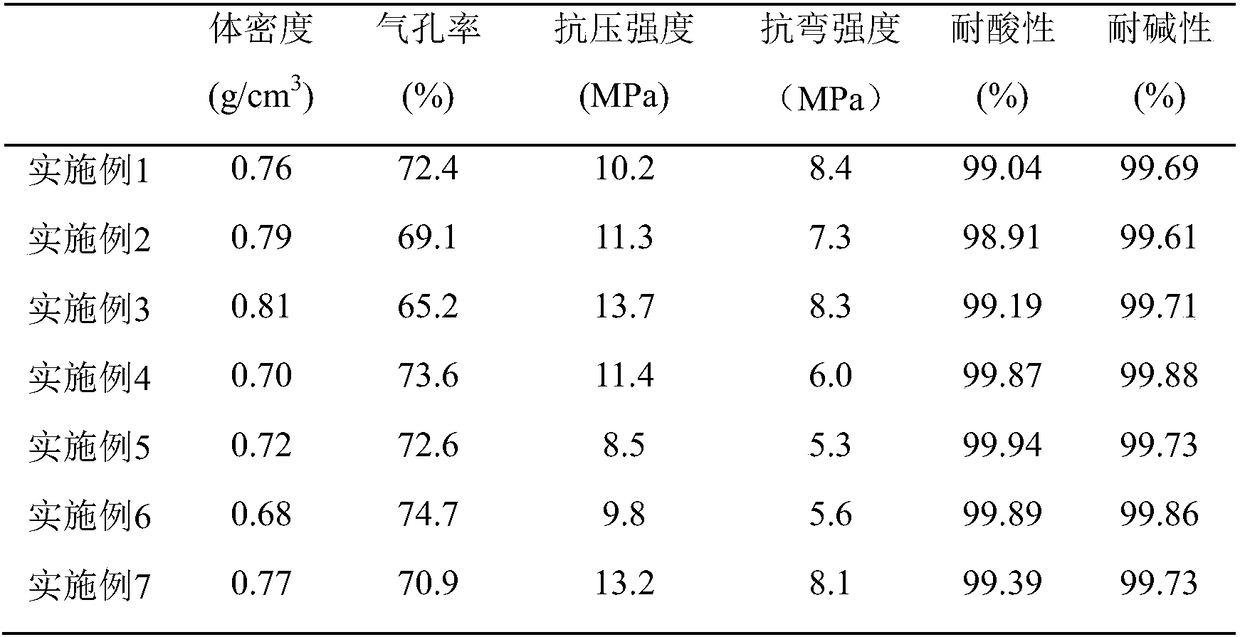

Embodiment 1

[0027] After weighing and uniformly mixing various raw materials according to the mass percentage of coal gangue 47.5%, fly ash 47.5%, and silica sand tailings 5%, Fe 2 o 3 The weight accounts for 3.61% of the total weight, and the water of 3-5% of the total weight of raw materials is used as a wetting agent. After mixing evenly, put it in a metal mold and press it into a foam ceramic body at 30MPa, and put it in a drying box for drying; Place the fully dried green body in a resistance furnace to raise the temperature to 1225°C at a constant speed of 5°C / min, keep it warm for 1 hour and then cool it down naturally. The bulk density of the prepared ceramic foam is 0.76g / cm 3 , The porosity is 72.4%, the compressive strength is 10.2MPa, the bending strength is 8.4MPa, the acid resistance is 99.04%, and the alkali resistance is 99.69%.

Embodiment 2

[0029] After weighing various raw materials according to the mass percentage of coal gangue 45%, fly ash 45%, and silica sand tailings 10%, and mix them uniformly, Fe 2 o 3 The weight accounts for 3.43% of the total weight, and the water of 3-5% of the total weight of the raw materials is used as a wetting agent, mixed evenly, put into a metal mold, pressed at 25MPa to form a foam ceramic body, and put into a drying box for drying; Put the fully dried green body in a box-type resistance furnace and raise the temperature to 1220°C at a constant speed of 5°C / min, keep it warm for 1 hour and then cool it down naturally. The bulk density of the prepared ceramic foam is 0.79g / cm 3 , the porosity is 69.1%, the compressive strength is 11.3MPa, the flexural strength is 7.3MPa, the acid resistance is 98.91%, and the alkali resistance is 99.61%.

Embodiment 3

[0031] After weighing and uniformly mixing various raw materials according to the mass percentage of coal gangue 57%, fly ash 38%, and silica sand tailings 5%, Fe 2 o 3 The weight accounts for 3.27% of the total weight, and the water of 3-5% of the total weight of raw materials is used as a wetting agent. After mixing evenly, put it in a metal mold and press it into a foam ceramic body at 30MPa, and put it in a drying box for drying; Put the fully dried green body in a box-type resistance furnace to raise the temperature to 1230°C at a constant speed of 5°C / min, keep it warm for 1 hour and then cool it naturally. The bulk density of the prepared ceramic foam is 0.81g / cm 3 , the porosity is 65.2%, the compressive strength is 13.7MPa, the bending strength is 8.3MPa, the acid resistance is 99.19%, and the alkali resistance is 99.71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com