Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

A technology of aromatic polyamide and conductive fiber, which is applied in fiber treatment, fiber type, textile and paper making, etc. It can solve problems such as metal plating is easy to fall off, low reactivity, affecting fiber conductivity and durability, etc., to increase roughness The degree and surface area, good electrical conductivity, and the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

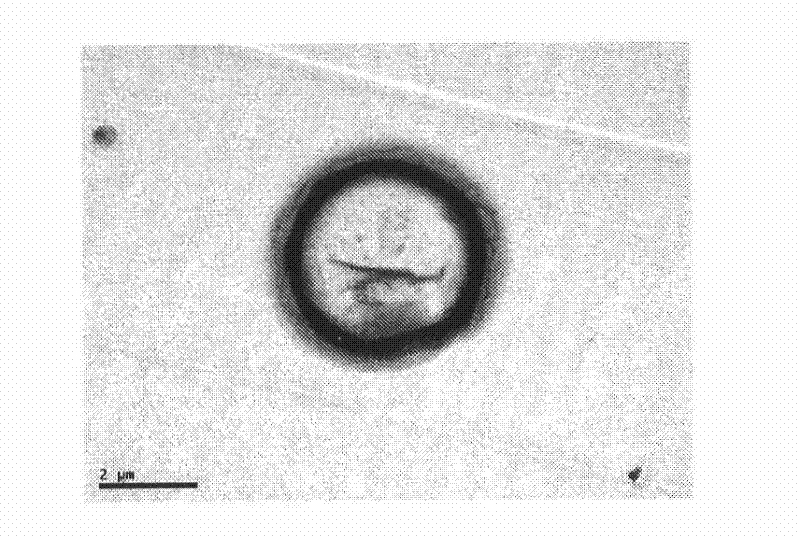

[0035] In this embodiment, the p-phenylene terephthalamide fiber is used as the base fiber.

[0036] Step 1: Remove oil, soak the fiber in 15g / L NaOH and 10g / L detergent aqueous solution at a temperature of 50°C, take it out after 10 minutes, rinse it with tap water; then put it in acetone solution, and ultrasonically clean it for 40 minutes Take it out and rinse it with tap water.

[0037] The second step: coarsening, immerse the fiber in 0.1mol / L metallization solvent, at room temperature, take it out after 10 minutes and rinse it clean.

[0038] The third step: sensitization, put the roughened fiber into an aqueous solution composed of 15g / L stannous chloride and 15ml / L hydrochloric acid for sensitization treatment, the temperature is 30°C, take it out after 20 minutes and rinse it 2-3 times .

[0039] Step 4: Activation. Put the roughened fiber into an aqueous solution composed of 0.3g / L palladium chloride and 3ml / L hydrochloric acid for sensitization treatment at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com