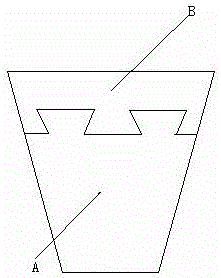

Compound brick with dovetail tenon type embedding structure and preparation method of compound brick

A mosaic structure and composite brick technology, applied in lighting and heating equipment, furnace components, furnaces, etc., can solve the problems of large interface stress, small contact area, thermal insulation damage, etc., and achieve the effect of improving thermal insulation performance and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

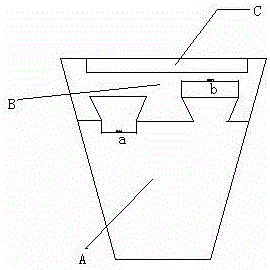

Embodiment 1

[0034] Embodiment 1 is attached figure 2 .Working layer A adopts magnesium aluminum spinel castable, and its properties are shown in Table 1. The lightweight insulation layer B is made of nano-micron aluminum-silicon castable, and its performance is shown in Table 1. The compound between them is compounded by dovetail tenon. The size of the large end of the dovetail groove is b, and the size of the small end is a. Both are required to meet the following conditions:

[0035] a≤0.97b

[0036] This can ensure that after the kiln is shut down, the size of the large end will still be larger than that of the small end after the size shrinks, so there will be no lottery and kiln collapse.

[0037] Table 1

[0038]

[0039] The composite brick is applied to the production of lime rotary kiln with a kiln chamber temperature of 1500°C. When the insulation layer length of the brick is 80mm and the working layer length is 170mm, the groove size is 10mm, and a 10mm high-temperatur...

Embodiment 2

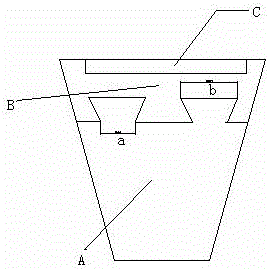

[0041] See attached image 3 .The working layer adopts high-aluminum unfired bricks, and its properties are shown in Table 2. The lightweight insulation layer B is made of nano-micron aluminum-silicon castable, and its properties are shown in Table 2. The composite between them is composited by dovetail groove. The size of the large end of the dovetail is b, and the size of the small end is a. Both are required to meet the following conditions:

[0042] a≤0.97b

[0043] This can ensure that after the kiln is shut down, the size of the large end will still be larger than that of the small end after the size shrinks, so there will be no lottery and kiln collapse.

[0044] Table 2

[0045]

[0046] The composite brick is applied to the rotary kiln lining with a kiln chamber temperature of 1600°C. When the insulation layer length of the brick is 80mm and the working layer length is 180mm, the groove size is 10mm, and a 10mm high-temperature nano-plate is placed inside. i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com