A cement-based solidified material for processing middle and low radioactive incineration ash and a method for processing middle and low radioactive incineration ash

A solidified material and low-radioactivity technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as high nuclide leaching rate, damaged packaging containers, and low waste packaging capacity, and achieve nuclide Low ion erosion rate, stable mechanical properties and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, preparation and solidification effect of cement-based solidified material for processing medium and low radioactive incineration ash

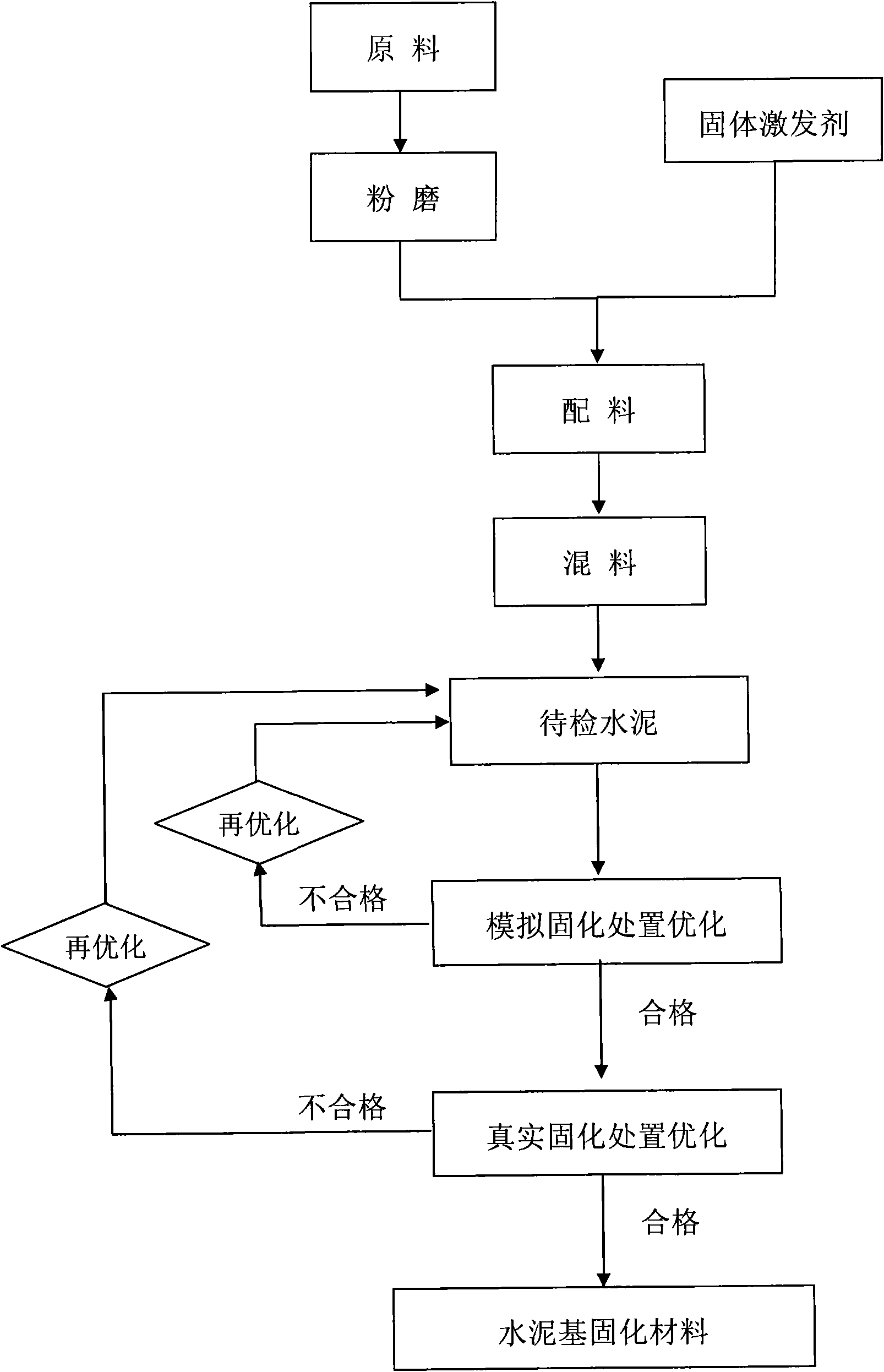

[0049] Such as figure 1 As shown, a solid activator is used to prepare a cement-based curing material and perform curing treatment.

[0050] Grinding: Grinding raw materials, including slag, zeolite, low-temperature calcined metakaolin and Huaxin P I 52.5 cement clinker (Portland cement), respectively grinding to 400±20m 2 / Kg, 100 mesh, 1000 mesh, 400±20m 2 / Kg.

[0051] Ingredients and Mixing:

[0052] Get 4.97Kg slag, 1.5Kg zeolite, 1.5Kg metakaolin and 0.7Kg cement clinker after grinding, then get 0.5Kg polymer latex powder and 0.8Kg self-made composite solid activator (by the silicic acid of 15 parts by weight) Sodium, 75 parts of sodium sulfate and 10 parts of calcium hydroxide), put it into the mixer, and add 0.03kg of high-efficiency water reducer (Nai series high-efficiency water reducer FDN) and mix evenly. T...

Embodiment 2

[0065] Embodiment 2, preparation and detection of cement-based solidified material for processing medium and low radioactive incineration ash

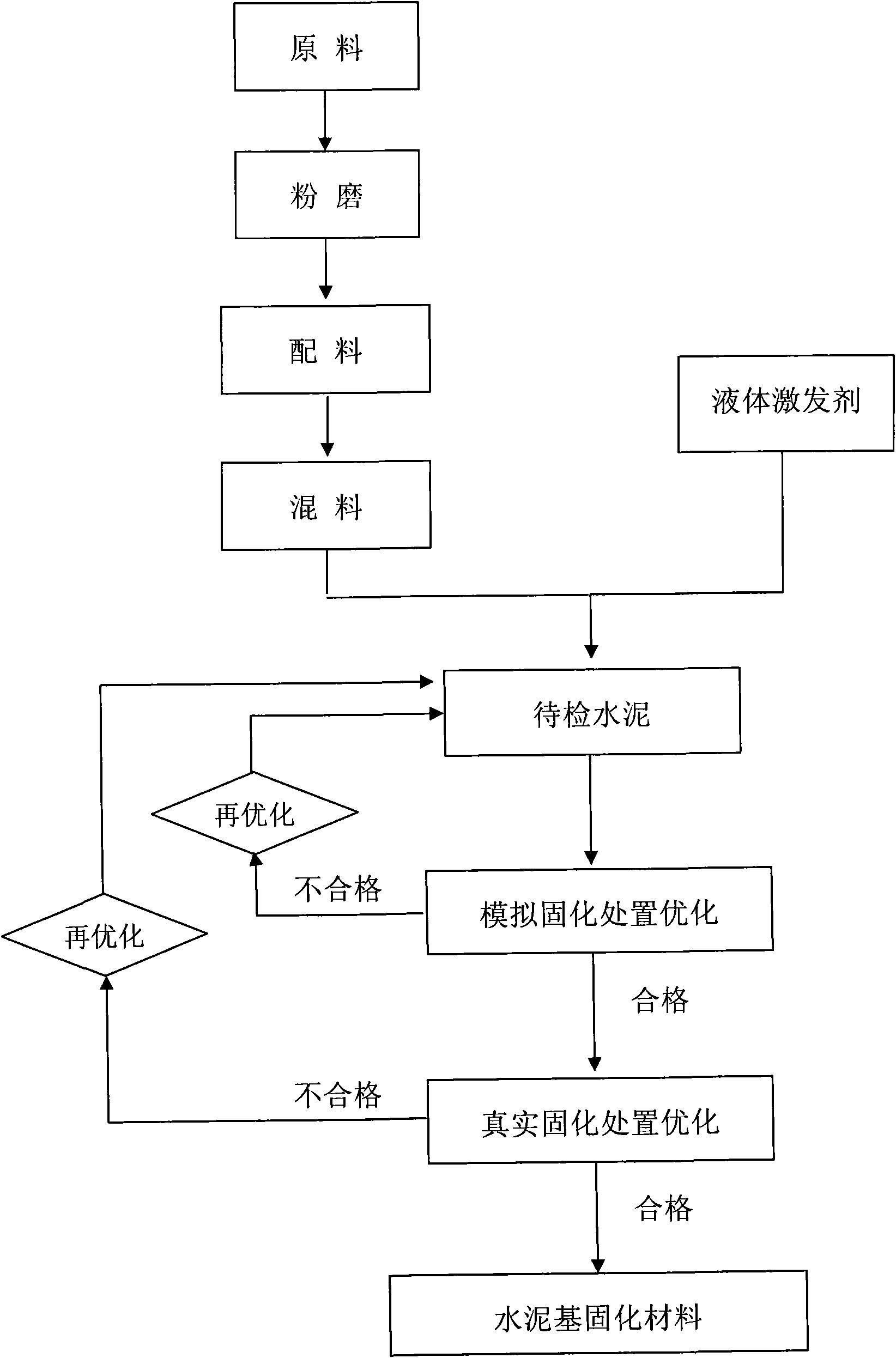

[0066] according to figure 2 As indicated, a liquid activator cement-based curing material was prepared.

[0067] Grinding: Grind slag, fly ash, zeolite, and Huaxin P I 52.5 cement clinker to 500±20m 2 / Kg, 450±20m 2 / Kg, 200 mesh, 450±20m 2 / Kg;

[0068] Mixture:

[0069] Take 6.0Kg of slag, 1.5Kg of fly ash, 1.5Kg of zeolite and 1.0Kg of Huaxin P I 52.5 cement clinker and mix evenly to obtain material A1 to be activated;

[0070] Take 6.5Kg of slag, 1.0Kg of fly ash, 2.0Kg of zeolite and 0.5Kg of Huaxin P I 52.5 cement clinker and mix evenly to obtain the material to be excited A2;

[0071] Take 5.5Kg of slag, 1.0Kg of fly ash, 3.0Kg of zeolite and 0.5Kg of Huaxin P I 52.5 cement clinker and mix them evenly to obtain the material to be activated A3;

[0072] According to high metal oxide incineration ash (from China Academy o...

Embodiment 3

[0076] Embodiment 3, preparation and detection of cement-based solidified material for processing medium and low radioactive incineration ash

[0077] Grinding: Grind slag, zeolite, metakaolin, and reference cement clinker (purchased from Beijing Xingfa Cement Co., Ltd.) to 400±20m 2 / Kg, 300 mesh, 1500 mesh and 500±20m 2 / Kg;

[0078] Mixture:

[0079] Take 6.55Kg of slag, 1.5Kg of zeolite, 1.5Kg of metakaolin, 0.4Kg of reference cement clinker and 0.05kg of Nai series high-efficiency water reducer FDN and mix evenly to obtain material C1;

[0080] Take 6.65g of slag, 1.2g of zeolite, 1.2Kg of metakaolin, 0.5Kg of polymer latex powder, 0.4Kg of reference cement clinker and 0.05kg of Nai series high-efficiency water reducer FDN and mix them uniformly to obtain material C2;

[0081] Get 6.02Kg slag, 1.5Kg zeolite, 1.5Kg metakaolin, 0.4Kg high-performance cement clinker and 0.5Kg composite solid activator (by weight 35 parts of sodium silicate, 55 parts of sodium sulfate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leaching rate | aaaaa | aaaaa |

| Activity | aaaaa | aaaaa |

| Leaching rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com