High toughness cement-based material-nonmetal fiber rib composite structure as well as application and application method thereof

A cement-based material, non-metal fiber technology, applied in the direction of structural elements, truss structure, building material processing, etc., can solve the problems of reduced bearing capacity, reduced durability, concrete cracking, etc., to improve bearing capacity and durability. , good electromagnetic shielding effect, the effect of reducing the aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

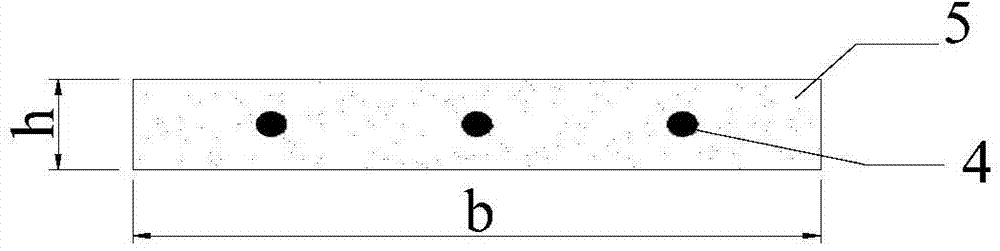

[0036] Example 1: 15mm thick basalt fiber reinforcement-PVA fiber reinforced cement-based material composite sheet structure example

[0037] The volume mixing rate of PVA fiber in the matrix is 2%, and the matrix slurry ratio: cement: fine sand: fly ash: metakaolin: silica fume: water: water reducing agent=1:1.43:1.43:0.29:0.14: 0.86:0.036; the cement type is 42.5 grade, the fine sand is 80-120 mesh, the fly ash is the first grade fly ash, the metakaolin is DX-80M type, the silica fume is micro silica fume, and the water reducer is polycarboxylic acid Salt water reducer, fiber reinforcement adopts basalt fiber reinforcement.

[0038] Test piece processing process: first put cement, fine sand, fly ash, metakaolin, and silica fume into the mixer and stir evenly for about 2-3 minutes; then weigh the corresponding weight of water, and mix the water reducer and Stir the water evenly, and put the weighed PVA fiber into the mixed liquid of water reducing agent and water to fully ...

Embodiment 2

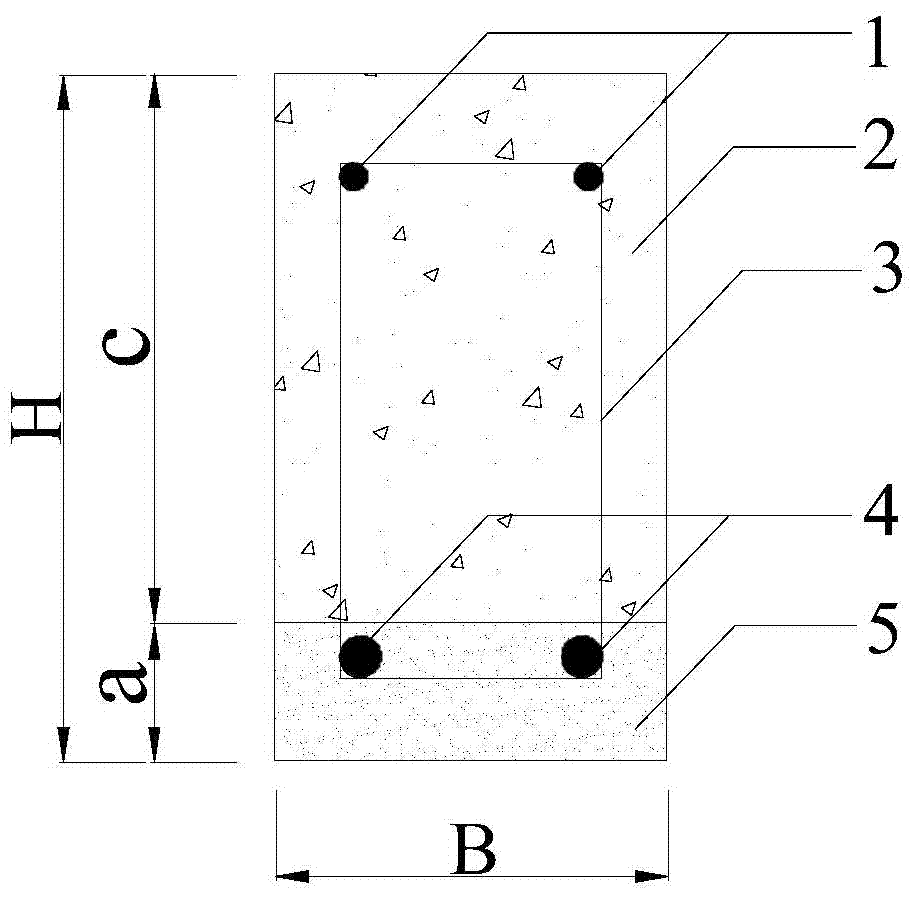

[0040] Example 2: An application example of high-toughness cement-based material-non-metal fiber reinforced composite thin plate replacing steel bar and concrete in the tension area of a concrete beam

[0041] Reinforcement cage binding: stirrups, Ф8HPB235 steel bars for vertical bars, and Ф12 basalt fiber composite bars (BFRP bars) for stressed longitudinal bars. The thickness of the top and bottom reinforcement protective layer is 20mm (the concrete thickness from the concrete surface to the stirrup surface).

[0042] Pouring composite beams: when pouring, pour PVA fiber-reinforced cement-based composite material with a thickness of 50mm into the formwork first, vibrate and compact it, and continue to pour C30 concrete with a thickness of 150mm on the surface before the initial setting of the cement-based composite material, and Shake again to firm up.

[0043] Wet curing: Remove the mold after 24 hours, put it in a standard curing room for 28 days.

[0044] The new comp...

Embodiment 3

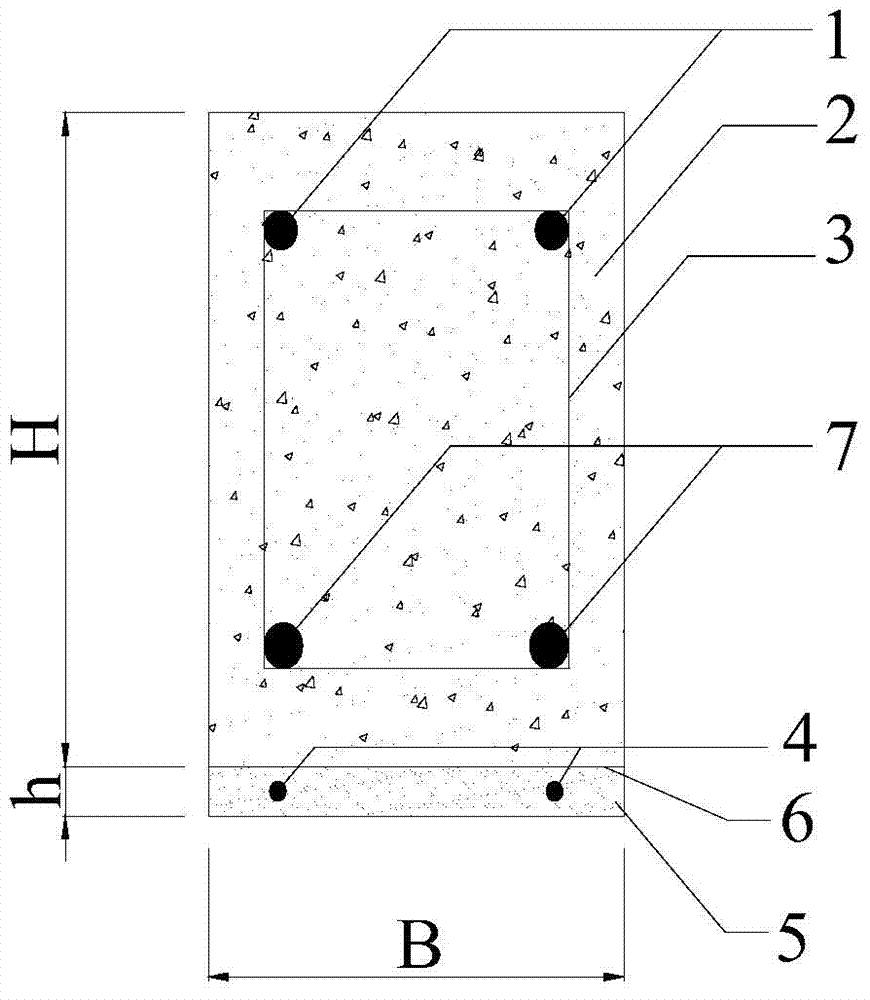

[0046] Example 3: Cast-in-place PVA fiber-reinforced cement-based material-carbon fiber reinforced composite thin plate reinforced concrete beam example

[0047] Concrete base surface treatment: Grind the concrete base surface with an angle grinder, and chisel the rough base surface with a flower hammer and an electric hammer to form random unevenness to increase the roughness of the bonding surface.

[0048] Implantation of rivets: pre-embed rivets at a certain interval on the bottom of the beam, use an electric hammer to vertically align the concrete on the bottom of the beam to drill holes, then remove the dust in the holes and inject glue into the holes, and then drive in special-shaped rivets one by one.

[0049] Flushing of floating dust on the base surface: Use high-pressure water to clean the powder ash and oil stains on the concrete surface and keep it in a moist state.

[0050] Spray reinforced concrete interface agent for reinforcement: before applying the interface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com