High-strength concrete mixed with low-temperature rice husk ash

A high-strength concrete and rice husk ash technology, which is applied in the field of high-strength concrete, can solve the problems of restricting the wide application of high-strength concrete, extremely high raw material requirements, and complicated processes, and achieve good volume stability and durability, rapid strength development, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

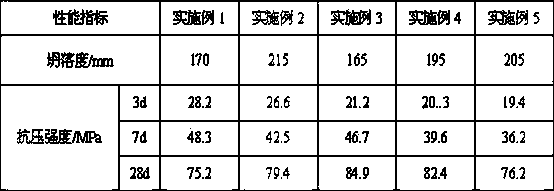

[0040] Embodiment 1, a kind of high-strength concrete mixed with low-temperature rice husk ash, according to 42.5 grade ordinary Portland cement 100, low-temperature rice husk ash 10, S105 slag powder 10, fly ash 5, crushed stone 250, river sand 200, Water 35, the weight ratio of polycarboxylate superplasticizer 0.05 is prepared. The performance test results are shown in Table 1.

Embodiment 2

[0041] Embodiment 2, a kind of high-strength concrete mixed with low-temperature rice husk ash, according to 42.5 grade ordinary Portland cement 100, low-temperature rice husk ash 30, S95 slag powder 40, fly ash 25, crushed stone 400, river sand 350, Water 65, the weight ratio of polycarboxylate superplasticizer 3.00 is prepared. The performance test results are shown in Table 1.

Embodiment 3

[0042]Embodiment 3, a kind of high-strength concrete mixed with low-temperature rice husk ash, according to 42.5 grade ordinary Portland cement 100, low-temperature rice husk ash 15, S95 slag powder 20, fly ash 10, crushed stone 300, river sand 250, Water 40, the weight ratio of polycarboxylate superplasticizer 1.00 is prepared. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com