Micro-expansion phosphorus slag powder grouting material and using method thereof

A technology of grouting material and phosphorus slag powder, which is applied in the field of building materials, can solve the problems of occupying large land, polluting soil and water bodies, etc., and achieve the effect of increasing density, improving viscosity and water retention performance, and stabilizing the grouting material system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

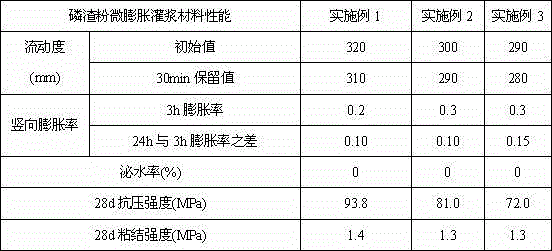

[0054] Example 1, a kind of phosphorus slag powder micro-expansion grouting material, according to 52.5 grade R type Portland cement 100, river sand 400, phosphorus slag powder 130, slag powder 30, phosphorus slag powder active activator 12, calcined magnesium oxide 20 , Lipid film calcium oxide 20, polypropylene fiber 0.5, wood fiber 0.3, modified attapulgite 20, defoamer 0.3, water reducer 0.8 by weight. According to 10% of the weight of phosphorus slag powder micro-expansion grouting material, add water and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0055] Example 2, a phosphorus slag powder micro-expansion grouting material, according to 42.5 grade R-type Portland cement 100, river sand 200, phosphorus slag powder 50, slag powder 150, phosphorus slag powder activation agent 2, calcined magnesium oxide 3 , Lipid film calcium oxide 30, polypropylene fiber 0.3, wood fiber 0.05, modified attapulgite 2, defoamer 0.01, water reducer 0.4 by weight. According to 15% of the weight of phosphorus slag powder micro-expansion grouting material, add water and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0056] Example 3, a kind of phosphorus slag powder micro-expansion grouting material, according to 52.5 grade R-type Portland cement 100, river sand 300, phosphorus slag powder 100, slag powder 100, phosphorus slag powder activation agent 8, calcined magnesium oxide 15 , Lipid film calcium oxide 3, polypropylene fiber 0.1, wood fiber 0.2, modified attapulgite 25, defoamer 0.1, water reducer 0.1 by weight. Add water to 20% of the weight of the phosphorous slag powder micro-expansion grouting material and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

[0057] Table 1 Example performance test results

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com