Concrete admixture based on iron tailing powder and preparation method of concrete admixture

A technology of iron tailings powder and admixture, which is applied in the field of concrete, can solve the problems of environmental pollution, seriousness, and low utilization rate, and achieve the effect of reducing costs and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

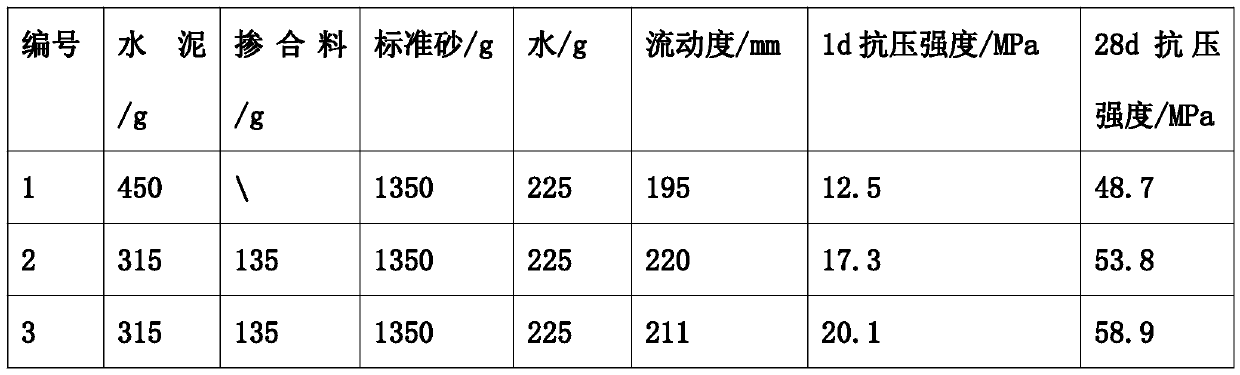

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a concrete admixture based on iron tailings powder is made of the following components in proportion by weight: iron tailings powder + natural gypsum is specifically 59.7%, and Class I fly ash is specifically 59.7%. 25%; S105 mineral powder is 15%, liquid functional regulator is 0.3%;

[0021] The content of SiO2 in the iron tailings used is 62.13%, the content of CaO is 5.12%, the content of MgO is 4.36%, the content of Fe2O3 is 10.23%, and the content of Al2O3 is 9.65%. %, water requirement ≤95%, loss on ignition ≤5.0%; SO3 content in S105 slag micropowder ≤4.0%, basic coefficient >1, vitreous content ≥90%, 28d activity index ≥105%.

[0022] A preparation method of a concrete admixture based on iron tailings powder, comprising the following steps:

[0023] Step 1: Dry the iron tailings in a blast drying oven at 105°C until constant weight and set aside;

[0024] Step 2: Mix the dried iron tailings and natural gypsum evenly...

Embodiment 2

[0029] A concrete admixture based on iron tailings powder, which is made of the following components by weight: iron tailings powder + natural gypsum is specifically 52.5%, Class I fly ash is specifically 23%; S105 ore The powder is specifically 24%, and the liquid functional regulator is specifically 0.5%;

[0030] The content of SiO2 in the iron tailings used is 62.13%, the content of CaO is 5.12%, the content of MgO is 4.36%, the content of Fe2O3 is 10.23%, and the content of Al2O3 is 9.65%. %, water requirement ≤95%, loss on ignition ≤5.0%; SO3 content in S105 slag micropowder ≤4.0%, basic coefficient >1, vitreous content ≥90%, 28d activity index ≥105%.

[0031] A preparation method of a concrete admixture based on iron tailings powder, comprising the following steps:

[0032] Step 1: Dry the iron tailings in a blast drying oven at 105°C until constant weight and set aside;

[0033] Step 2: Mix the dried iron tailings and natural gypsum evenly in a ratio of 10:1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com