Composite binding material doped with low-temperature burned clay and preparation method of composite binding material

A technology of composite cementitious materials and fired clay, which is applied in the field of building materials, can solve the problems such as the difficulty of direct utilization of coal series kaolin, and achieve the effects of inhibiting early shrinkage cracking, dense concrete structure, and accelerated hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

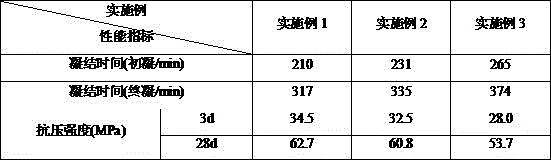

[0036] Example 1, a composite cementitious material mixed with low-temperature calcined clay. The coal-series kaolin is crushed and then calcined at 550°C for 1 hour. The calcined coal-series kaolin is quenched with wind, and the cooled calcined clay is powdered together with gypsum. Grind until the specific surface area is 300m 2 / kg; and then mixed with Portland cement, slag powder, fly ash and expansion agent to obtain a composite cementitious material. The weight ratio of each component is: Portland cement 100, low temperature burnt clay 10, S95 slag powder 5, fly ash 5, gypsum 2, expansion agent 2. The performance test results are shown in Table 1.

Embodiment 2

[0037] Example 2, a composite cementitious material mixed with low-temperature calcined clay. The coal-series kaolin is crushed and then calcined at 550°C for 1 hour. The calcined coal-series kaolin is quenched with wind, and the cooled calcined clay is powdered together with gypsum. Grind until the specific surface area is 350m 2 / kg; and then mixed with Portland cement, slag powder, fly ash and expansion agent to obtain a composite cementitious material. The weight ratio of each component is: Portland cement 100, low temperature burnt clay 30, S95 slag powder 15, fly ash 15, gypsum 3, expansion agent 5. The performance test results are shown in Table 1.

Embodiment 3

[0038] Example 3, a composite cementitious material mixed with low-temperature calcined clay. The coal-series kaolin is crushed and then calcined at 600°C for 1 hour. The calcined coal-series kaolin is quenched with wind, and the cooled calcined clay is powdered together with gypsum. Grind until the specific surface area is 350m 2 / kg, and then mixed with Portland cement, slag powder, fly ash and expansion agent to obtain a composite cementitious material. The weight ratio of each component is: Portland cement 100, low temperature burnt clay 50, S105 slag powder 25, fly ash 25, gypsum 5, expansion agent 8. The performance test results are shown in Table 1.

[0039] Table 1 embodiment performance test result

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com