A kind of preparation method of small size hollow mesoporous silica nanoparticles

A technology of hollow mesoporous and silica, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of difficult effective synthesis, troublesome operation, unfavorable practical application and large-scale production, etc., and achieves the synthetic method Simple, good templating agent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

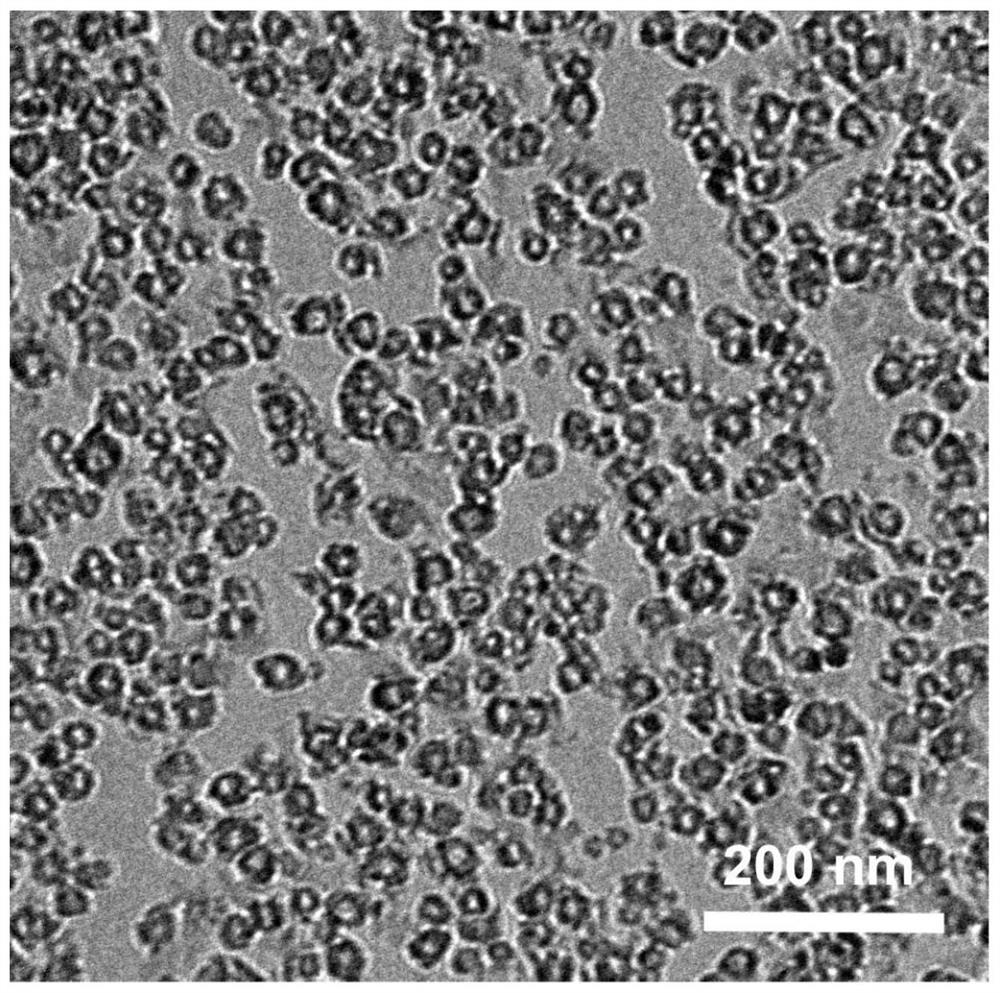

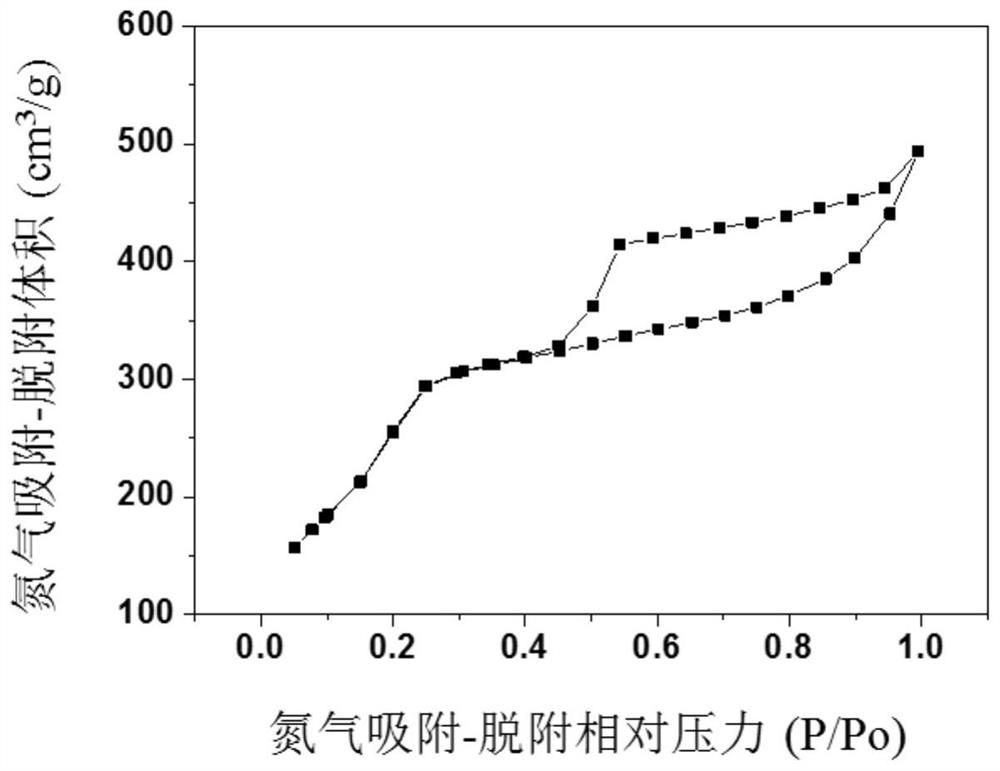

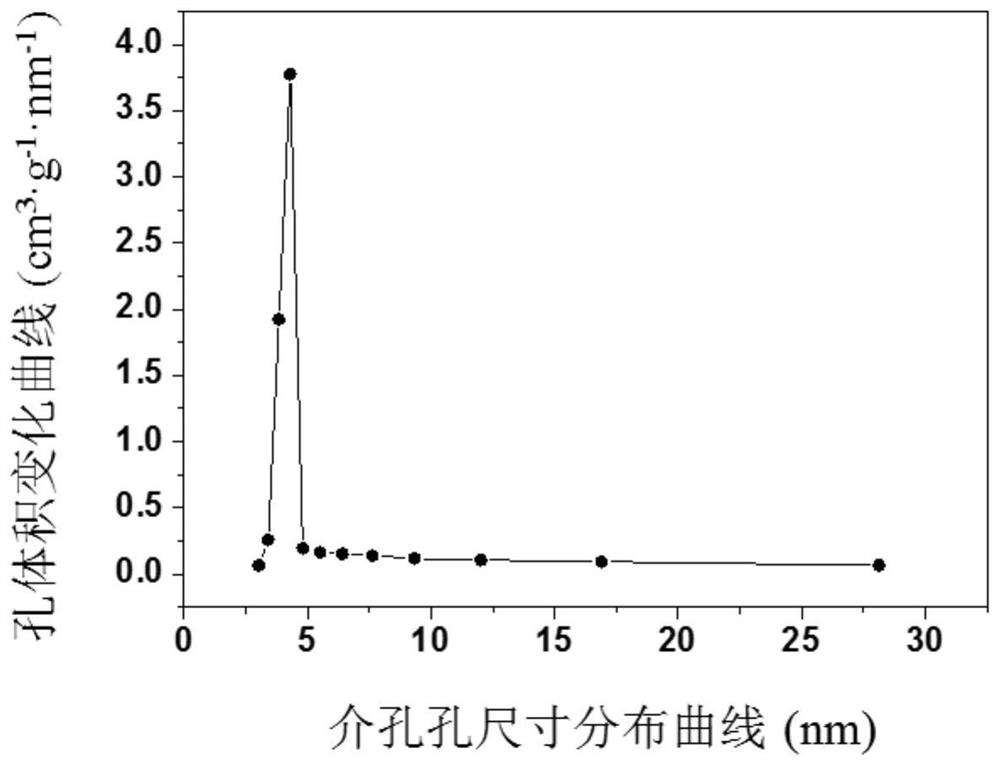

Embodiment 1

[0021] A preparation method of small-sized hollow mesoporous silica nanoparticles, comprising the following steps: adding ammonia water to an ethanol aqueous solution with a volume concentration of 37.5% to make the final concentration 0.14 mol / L; adding LiOH aqueous solution to make the LiOH final concentration 0.14 mol / L 0.43×10 -3 mol / L and cetyltrimethylammonium bromide to give a final concentration of cetyltrimethylammonium bromide of 4.73 × 10 -3 mol / L, the reaction temperature is constant to 30 ℃, after cetyl trimethyl ammonium bromide is dissolved, add tetraethyl orthosilicate ethanol solution dropwise, so that the final concentration of tetraethyl orthosilicate is 0.10mol / L , after the dropwise addition, continue to stir at a constant temperature of 30 ° C for 3 hours, filter with a 200 nm filter membrane, and finally dry the solid, calcine, and remove impurities to obtain small-sized hollow mesoporous silica with a size of less than 30 nm. Nanoparticles. The rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com