Method for completely dissolving and rapidly hydrolyzing cellulose and application thereof

A technology of completely dissolving and cellulose, applied in the field of biomass dissolving and hydrolysis, can solve the problems such as the influence of cellulose dissolving that has not been involved, and achieve the effect of lowering the complete dissolving temperature, prolonging the service life and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0033] In order to better understand the essence of the present invention, the technical effect of the present invention and its application prospect in industrial production will be described below with a complete dissolution experiment of cellulose powder.

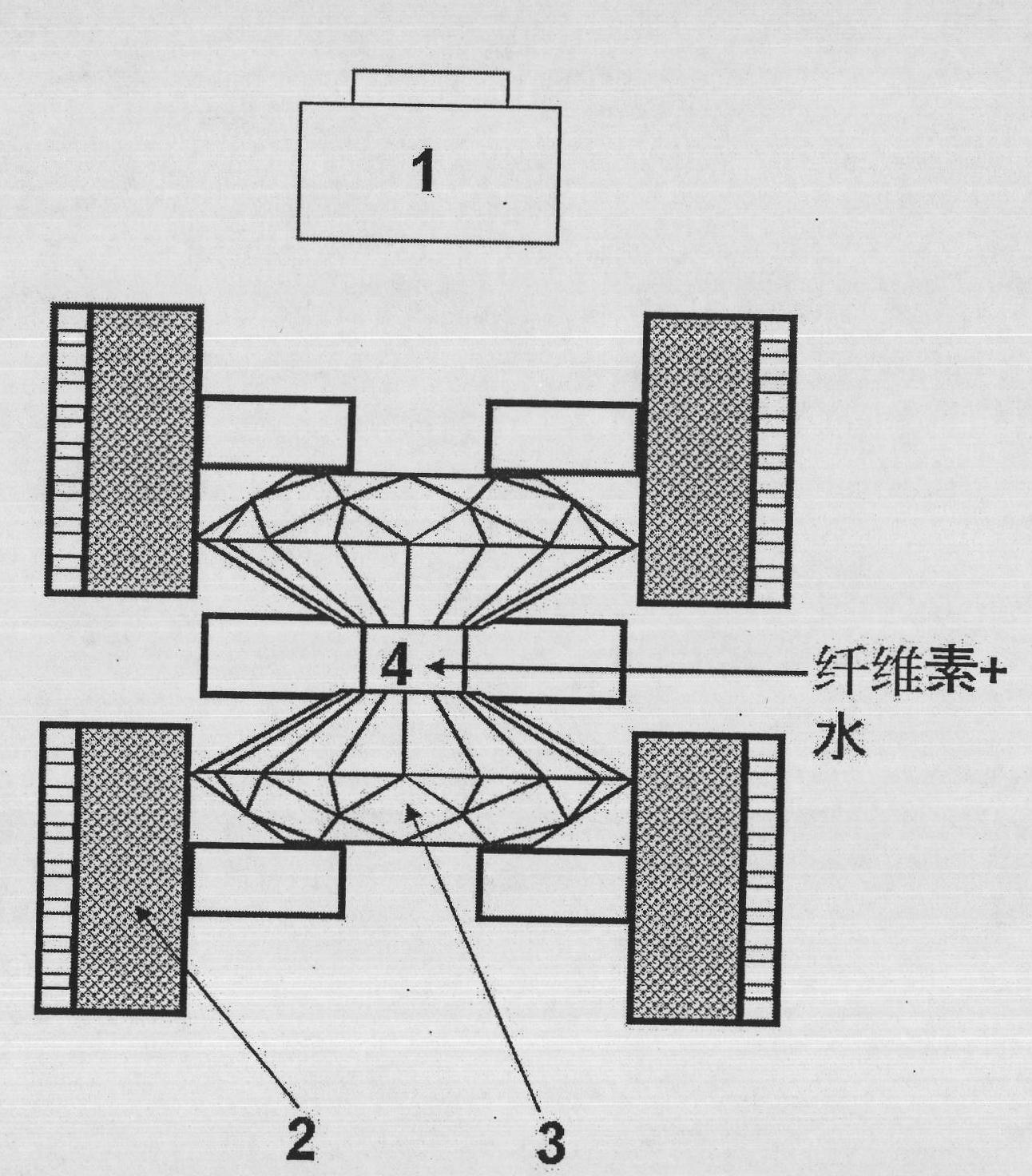

[0034] Such as figure 1 As shown, the experimental device is a miniature visible diamond reactor (Diamond Anvil Cell), which can rapidly heat the water in the reaction chamber to a high temperature, and can observe the process of dissolving cellulose in the water. A small hole with a diameter of 500 μm is opened on an iron sheet with a thickness of 250 μm to form a reaction chamber 4 with a volume of 50 nL. After water and cellulose were loaded into the reaction chamber 4, the upper and lower diamonds 3 squeezed the small hole to seal the hole and generate pressure. If the two diamonds are loosened, nitrogen gas can enter the small hole and generate bubbles. By adjusting the size of the bubbles, different densities of ...

example 1

[0037] Put cellulose powder and pure water in the reactor, the cellulose concentration is 30%, the heating rate is set at 12.1°C / s; the water density is 887kg / m 3 ;

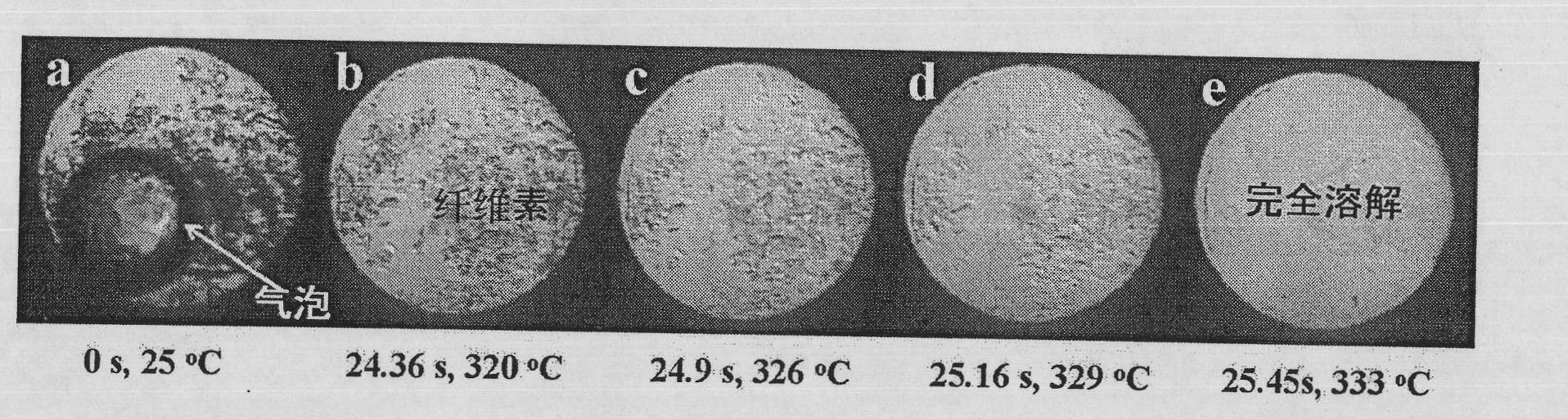

[0038] Such as figure 2 Shown:

[0039] a: Cellulose is suspended in water and air bubbles before heating;

[0040] b: Heating for 24.36s, when the temperature reaches 320°C, the cellulose becomes transparent and begins to dissolve (bubbles disappear at 180°C);

[0041] c: Heating for 24.9s, when the temperature reaches 326°C, more cellulose dissolves;

[0042] d: After heating for 25.16s, when the temperature reaches 329°C, most of the cellulose dissolves;

[0043] e: Heating for 25.45s, as the temperature further rises to 333°C (260MPa), the cellulose is completely dissolved, and the dissolution time is 1.09s.

[0044] After the reaction, the reactor was opened, and the sugar-like substance remained on the surface of the diamond. Infrared analysis showed that the substance had been hydrolyzed and had the c...

Embodiment 1

[0066] Embodiment 1 (pure water)

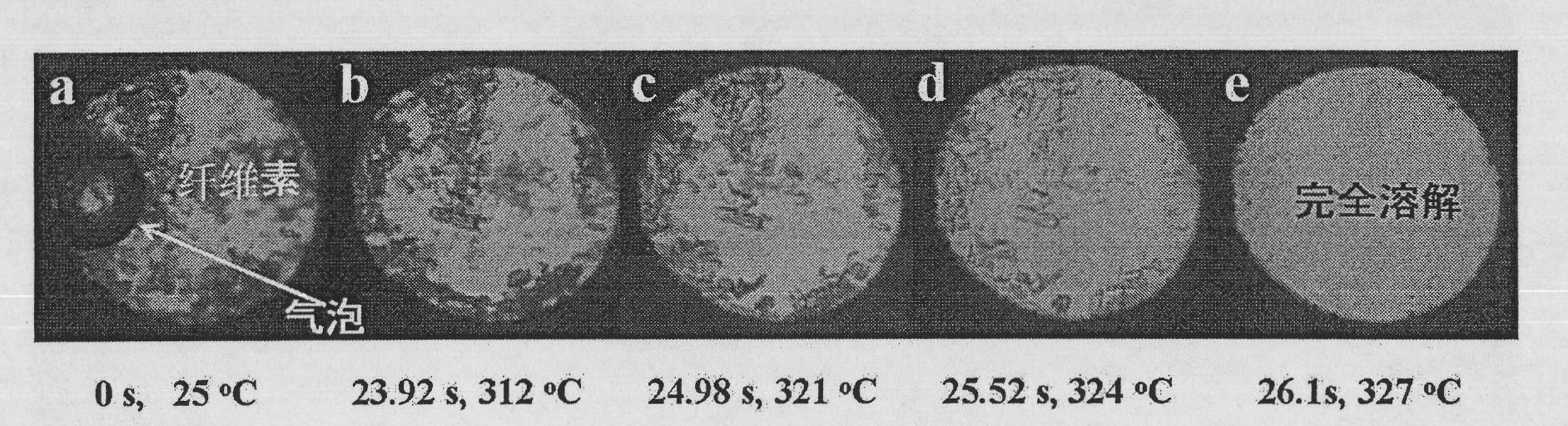

[0067] Put the cellulose in pure water to form a cellulose material; heat the pure water to 349°C; mix the pure water and cellulose material into the reactor, the cellulose concentration after mixing is 20%, and the water density is set to 594kg / m 3 , rapidly heated to 349°C, the heating rate is 10.4°C / s, and the cellulose can be completely dissolved in 1.05 seconds to 326°C (12MPa). Cellulose is hydrolyzed into polysaccharides and glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com