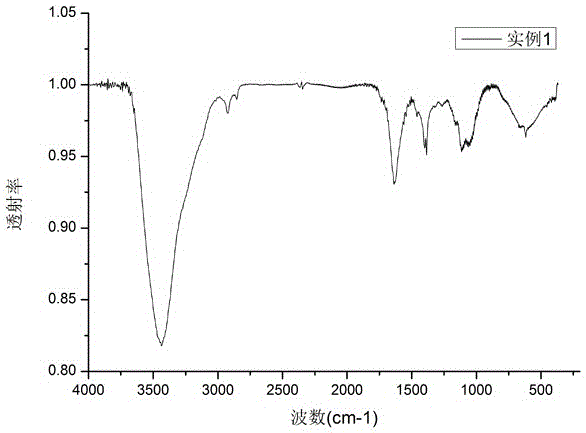

Titanium dioxide/graphene nanocomposite, and normal-temperature preparation method and application thereof

A nanocomposite material, graphene composite technology, applied in chemical instruments and methods, chemical/physical processes, photosensitive equipment, etc., can solve heating and other problems, and achieve the effects of low energy consumption, good stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

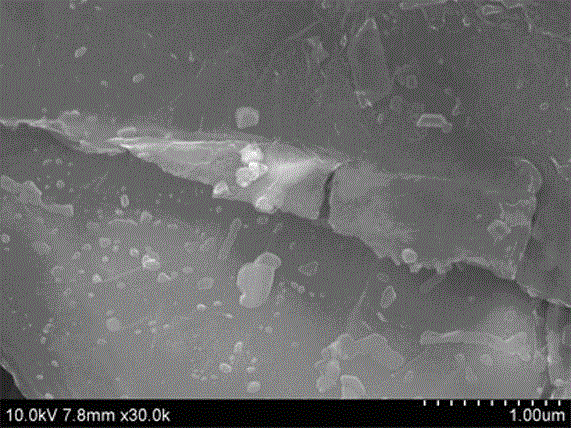

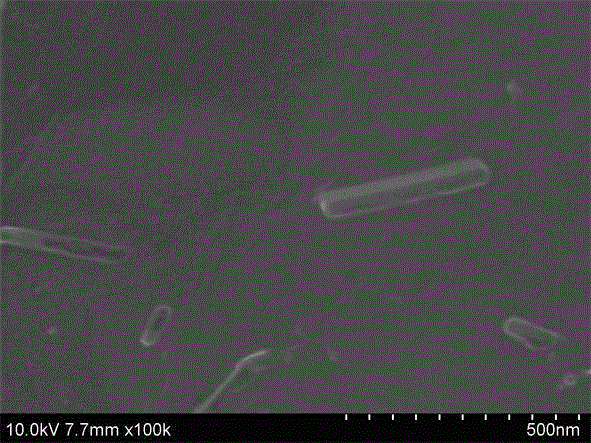

Embodiment 1

[0039] 1. Weigh raw materials: the mass ratio of graphite oxide to ethanol is 1:300, the mass ratio of graphite oxide to sodium borohydride and tetrabutyl titanate is 1:2:300, and the mass ratio of tetrabutyl titanate to hydrolysis inhibitor (ice Acetic acid) mass ratio is 1:0.3, tetrabutyl titanate and deionized water mass ratio is 1:0.3;

[0040] 2. The graphite oxide weighed according to step 1 is in ethanol, and ultrasonically dispersed for 0.5 hours to obtain a graphene oxide suspension, which is magnetically stirred at room temperature;

[0041] 3. Add the sodium borohydride weighed in step 1 to the graphene oxide suspension in step 2, stir magnetically for 20 hours at room temperature, wash the resulting solution with ethanol, dissolve the filter cake with ethanol to obtain graphene dispersion liquid;

[0042] 4. Add the tetra-n-butyl titanate weighed in step 1 to the graphene dispersion obtained in step 3 and magnetically stir for 2 hours, then add a hydrolysis inhib...

Embodiment 2

[0046] 1. Weigh raw materials: the mass ratio of graphite oxide to ethanol is 1:500, the mass ratio of graphite oxide to sodium sulfide and tetrabutyl titanate is 1:0.5:300, tetrabutyl titanate and hydrolysis inhibitor (36.7wt % hydrochloric acid) mass ratio is 1:0.2, tetrabutyl titanate and deionized water mass ratio is 1:0.1;

[0047] 2. The graphite oxide weighed in step 1 is dispersed in isopropanol by ultrasonic dispersion for 0.5 hours to obtain a graphene oxide suspension, which is magnetically stirred at room temperature;

[0048] 3. Add the sodium borohydride weighed in step 1 to the graphene oxide suspension in step 2, stir magnetically for 30 hours at room temperature, wash the resulting solution with ethanol, dissolve the filtered filter cake with isopropanol to obtain graphite olefin dispersion;

[0049] 4. Add the tetrabutyl titanate weighed in step 1 to the graphene dispersion obtained in step 3 and stir magnetically for 2 hours, then add a hydrolysis inhibito...

Embodiment 3

[0053] 1. Weigh raw materials: the mass ratio of graphite oxide to ethanol is 1:800, the mass ratio of graphite oxide to sodium borohydride and titanium sulfate is 1:0.5:300, titanium sulfate and hydrolysis inhibitor (30wt%H 2 SO 4 ) mass ratio is 1:0.3, titanium sulfate and deionized water mass ratio is 1:0.2;

[0054] 2. The graphite oxide weighed according to step 1 is in ethanol, and ultrasonically dispersed for 1 hour to obtain a graphene oxide suspension, which is magnetically stirred at room temperature;

[0055] 3. Add the sodium borohydride weighed in step 1 to the graphene oxide suspension in step 2, stir magnetically for 30 hours at room temperature, wash the resulting solution with ethanol, dissolve the filter cake with ethanol to obtain graphene dispersion liquid;

[0056] 4. Add the titanium sulfate weighed in step 1 into the graphene dispersion obtained in step 3 and stir it magnetically for 4 hours, then add a hydrolysis inhibitor (30wt%H 2 SO 4 ), after 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com