GRC inorganic non-combustible composite material lightweight box

A composite material and lightweight technology, applied in the field of building materials, can solve the problems of heavy weight, low strength and easy damage of the main body of the cement mortar box, and achieve the effect of good sound insulation and anti-drip seepage, high fire protection level, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

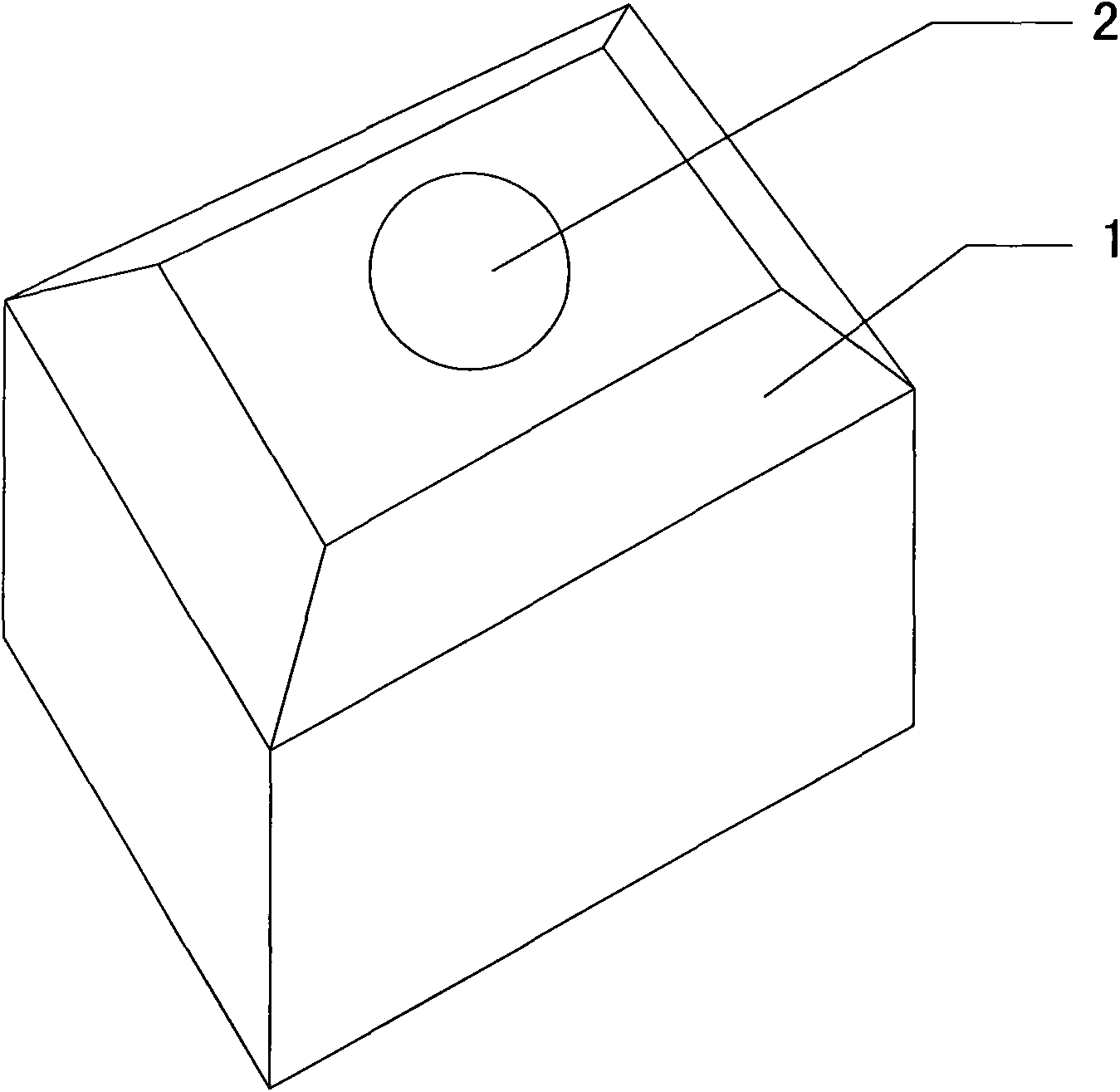

Image

Examples

Embodiment 1

[0015] A light box made of GRC inorganic non-combustible composite material of the present invention comprises a box body, the box body is a box body formed by integral casting of a glass fiber reinforced concrete mold or splicing after plate casting, and the glass fiber reinforced concrete includes a mass percentage of 20 % cement, 25% sand, 30% perlite powder, 20% water, 1-2% glass fiber and the rest polymers, additives or pozzolanic active materials; such glass fiber reinforced concrete, although Lighter in weight, but higher in strength and high in fire rating.

Embodiment 2

[0017] A GRC inorganic non-combustible composite lightweight box of the present invention, the glass fiber reinforced concrete includes 30% cement, 25% sand, 25% perlite powder, 15% water, and 1-2% by mass percentage. Glass fiber and the rest of the polymer, additives or pozzolanic active materials; such glass fiber reinforced concrete, although light in weight, has high strength and high fire rating.

Embodiment 3

[0019] A GRC inorganic non-combustible composite lightweight box of the present invention, the glass fiber reinforced concrete includes 26% cement, 25% sand, 28% perlite powder, 18% water, and 1.5% glass in mass percentages. fibers and the remaining polymers, additives or pozzolanic active materials; although such glass fiber reinforced concrete is light in weight, it has high strength and high fire protection rating, and the GRC inorganic non-combustible composite lightweight box made of it In addition to the above, it is also integrally formed with the cast-in-place concrete structure: there are no construction joints, it is beautiful and has good sound insulation and anti-drip and seepage effects, and can better adapt to the construction needs of cast-in-place two-way dense ribbed slabs.

[0020] In the light-weight box made of GRC inorganic non-combustible composite material of the present invention, the cement is rapid-hardening sulfoaluminate cement, low-alkalinity sulfoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com