Method for preparing volcanic ash active material from building residue soil

A technology of pozzolanic activity and construction slag, applied in cement production and other directions, can solve the problems of low clay backfill solidification strength, high moisture content, and inability to backfill, and achieve the effect of solving waste stacking, high utilization rate, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

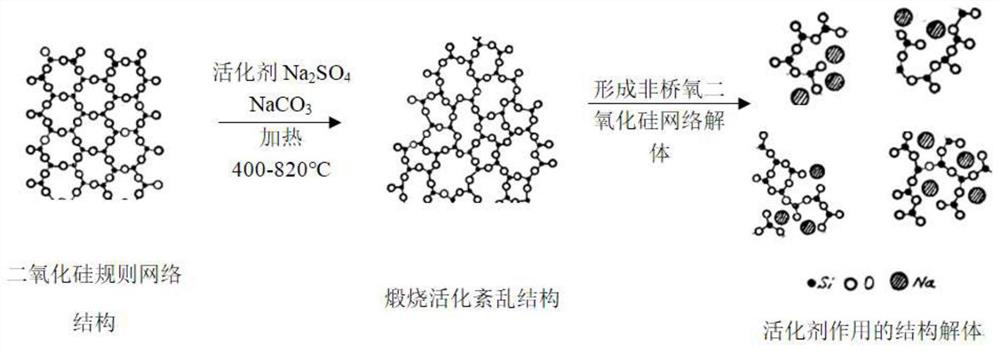

[0046] Embodiment 1: the preparation method of pozzolanic active material of the present invention, comprises the following steps:

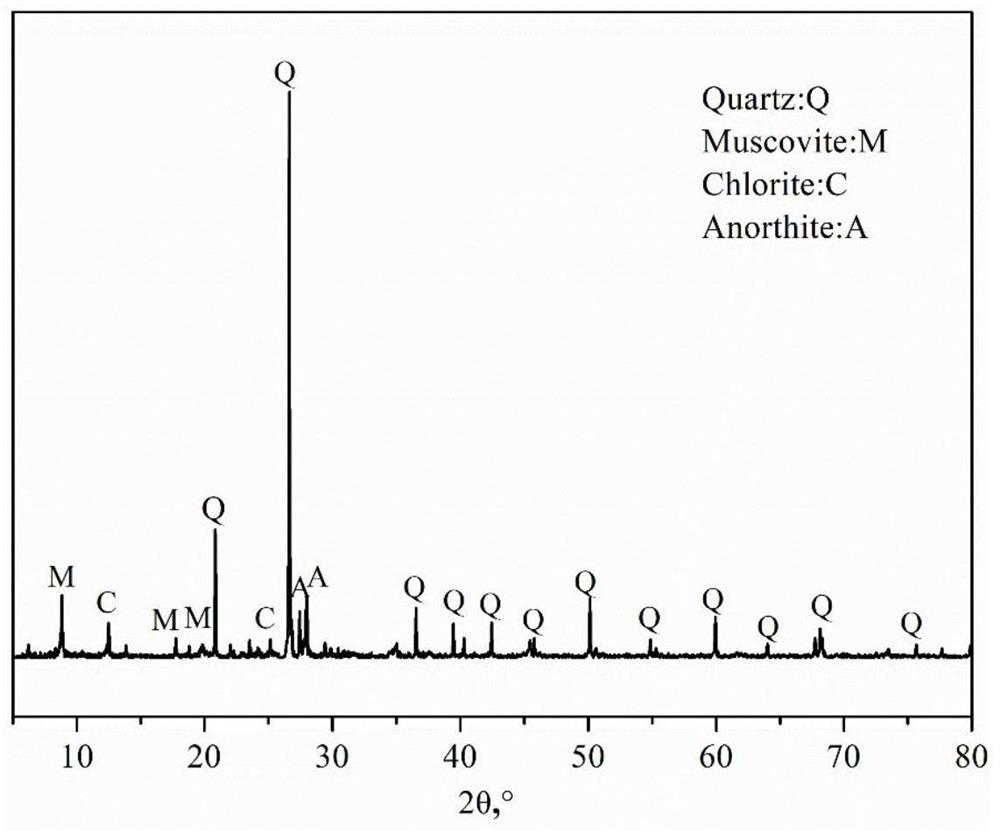

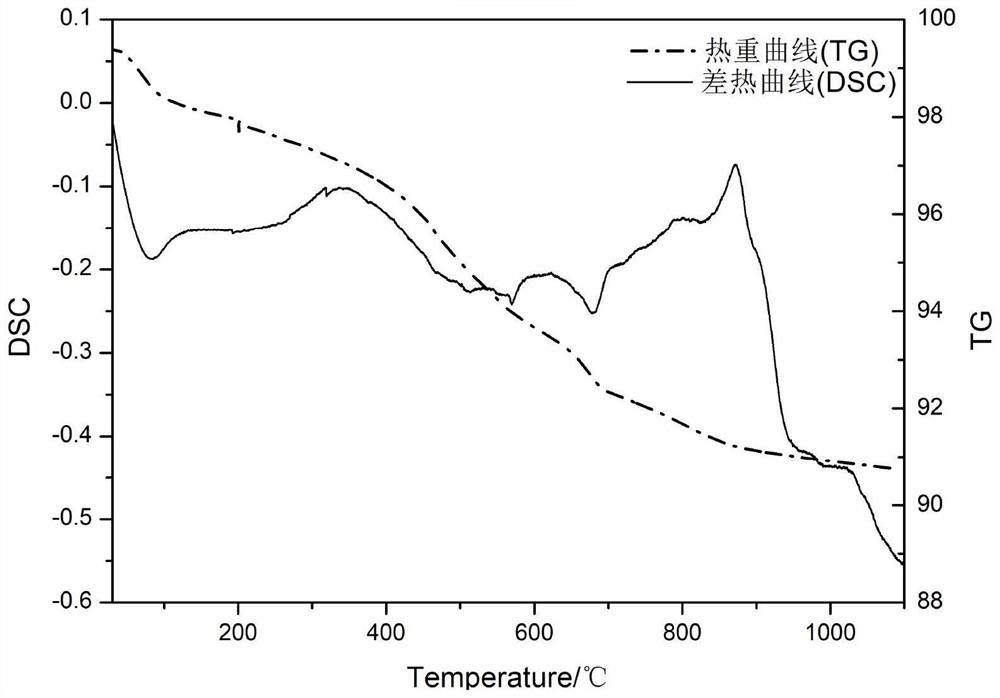

[0047] (1) Put Ningbo clay with the ingredients shown in Table 1 into an oven and dry it at 105°C for 24 hours to remove moisture;

[0048] (2) Anhydrous sodium sulfate is configured into a 20wt% aqueous solution;

[0049] (3) Put Ningbo clay into a mixer, then spray sodium sulfate aqueous solution, spray while stirring, and stir for 1-2 minutes to make a mixture. The mass ratio of Ningbo clay and sodium sulfate aqueous solution is 100:10.

[0050] (4) Calcining the above-mentioned mixture, the heating rate is controlled at 10° C. / min, the calcination temperature is 400° C., the holding time is 4 hours, and then the temperature is naturally cooled to room temperature.

[0051] (5) Put the above-mentioned calcined materials into a ball mill for ball milling, control 200-mesh sieve to less than 5% to obtain activated Ningbo clay, that is, pozzolan...

Embodiment 2

[0056] Embodiment 2: the preparation method of pozzolanic active material of the present invention, comprises the following steps:

[0057] (1) Put Ningbo clay in an oven and dry it at 105°C for 24 hours to remove moisture;

[0058] (2) Anhydrous sodium sulfate is configured into a 20wt% aqueous solution;

[0059] (3) Put Ningbo clay into a mixer, then spray sodium sulfate aqueous solution, spray while stirring, and stir for 1-2 minutes to make a mixture. The mass ratio of Ningbo clay and sodium sulfate aqueous solution is 100:10.

[0060] (4) Calcining the above mixture, the heating rate is controlled at 10° C. / min, the calcination temperature is 600° C., the holding time is 2 hours, and then the temperature is naturally cooled to room temperature.

[0061] (5) Put the above-mentioned calcined materials into a ball mill for ball milling, control 200-mesh sieve to less than 5% to obtain activated Ningbo clay, that is, pozzolan active material.

[0062] According to "GB / T 129...

Embodiment 3

[0066] Embodiment 3: the preparation method of pozzolanic active material of the present invention, comprises the following steps:

[0067] (1) Put Ningbo clay in an oven and dry it at 105°C for 24 hours to remove moisture;

[0068] (2) Anhydrous sodium sulfate is configured into a 20wt% aqueous solution;

[0069] (3) Put Ningbo clay into a mixer, then spray sodium sulfate aqueous solution, spray while stirring, and stir for 1-2 minutes to make a mixture. The mass ratio of Ningbo clay and sodium sulfate aqueous solution is 100:5.

[0070] (4) Calcining the above mixture, the heating rate is controlled at 5° C. / min, the calcination temperature is 800° C., the holding time is 1 hour, and then the temperature is naturally cooled to room temperature.

[0071] (5) Put the above-mentioned calcined materials into a ball mill for ball milling, control 200-mesh sieve to less than 5% to obtain activated Ningbo clay, that is, pozzolan active material.

[0072] According to "GB / T 12957-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com