Flame-retardant polybutylene terephthalate resin composition and moldings

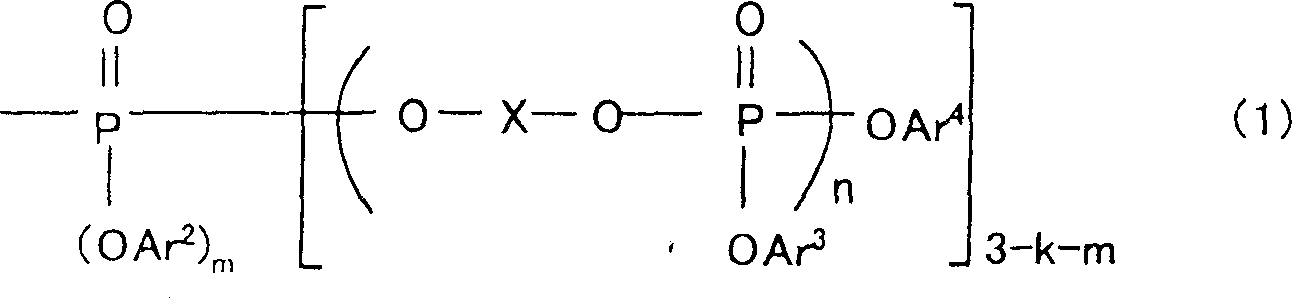

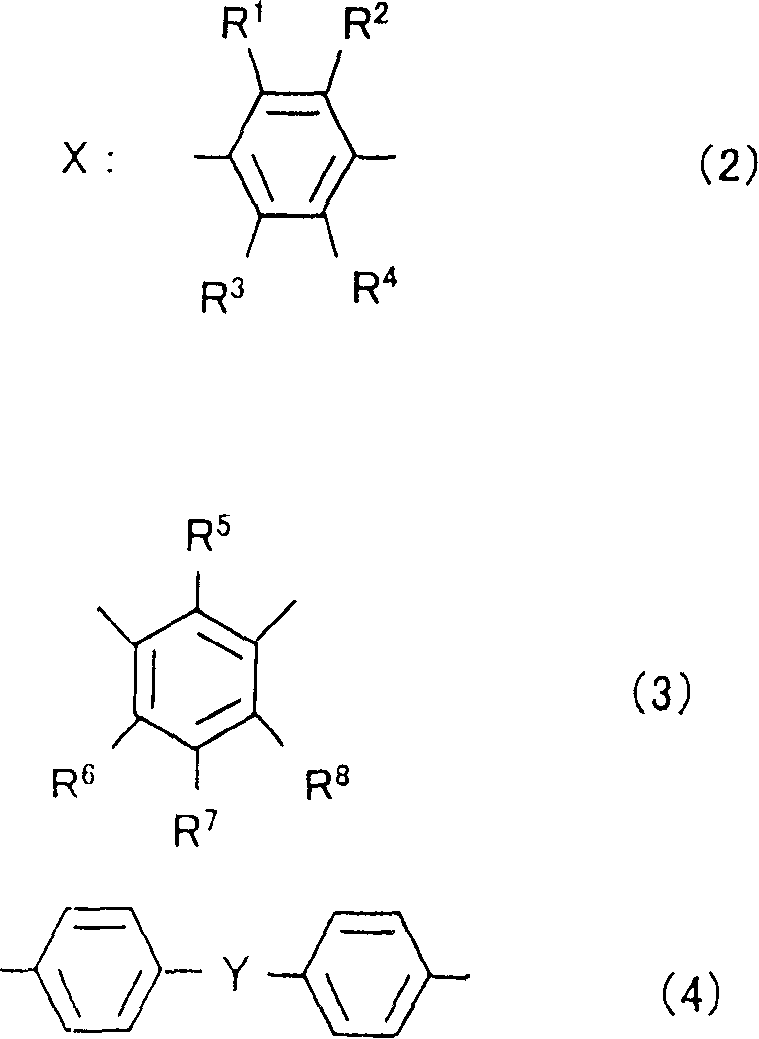

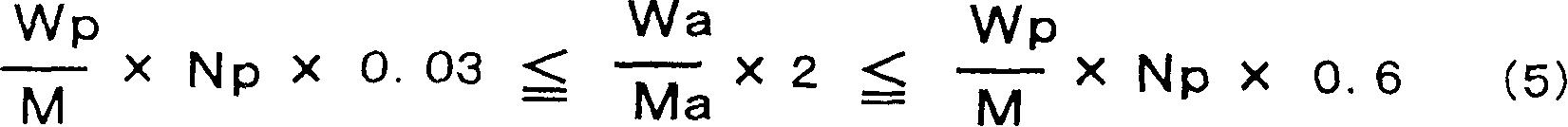

一种聚对苯二甲酸丁二醇酯树脂、聚对苯二甲酸丁二醇酯的技术,应用在阻燃性聚对苯二甲酸丁二醇酯树脂组合物及成型品领域,能够解决耐水解性、金属污染性差、芳香族磷酸酯渗移、机械强度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] The effects of the present invention will be described in more detail below through examples. Here, % and parts all represent % by weight and parts by weight, and " / " in a reference example means copolymerization. The measuring method of each characteristic is as follows.

reference example 1

[0129] Reference Example 1 (A) Polybutylene terephthalate resin (hereinafter abbreviated as PBT)

[0130] Toray PBT-1100S (manufactured by Toray Corporation) was used as PBT having an intrinsic viscosity of 0.85 (25° C., o-chlorophenol solvent).

reference example 2

[0131] Reference Example 2 (A) Polyethylene terephthalate resin (hereinafter abbreviated as PET)

[0132] Mitsui PETJ005 (manufactured by Mitsui Petto Plastic Co., Ltd.) was used as PET having an intrinsic viscosity of 0.65 (25° C., 1:1 mixed solvent of phenol / tetrachloroethane).

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility coefficient | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com