Phosphorus slag-based concrete and preparation equipment thereof

A technology for concrete and phosphorus slag, applied in the field of concrete, can solve the problems of polluted groundwater, environmental pollution, polluted water quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Modified phosphorus slag powder 20%, fly ash 10%, cement 40%, phosphogypsum 15%, additive 1%, slag sand 14%.

[0034] The additive is sodium aluminate.

[0035] The modified phosphorus slag powder is composed of phosphorus slag powder, desulfurized gypsum and metakaolin, and the mass fraction of the phosphorus slag powder, desulfurized gypsum and metakaolin is 1:0.4:0.2:0.2.

Embodiment 2

[0037] Modified phosphorus slag powder 30%, fly ash 15%, cement 30%, phosphogypsum 10%, additive 2%, slag sand 13%.

[0038] Described additive adopts sodium sulfate.

[0039] The modified phosphorus slag powder is composed of phosphorus slag powder, desulfurized gypsum and metakaolin, and the mass fraction of the phosphorus slag powder, desulfurized gypsum and metakaolin is 1:0.4:0.2:0.2.

Embodiment 3

[0041] Modified phosphorus slag powder 40%, fly ash 20%, cement 20%, phosphogypsum 5%, additive 3%, slag sand 12%.

[0042] The additive uses sodium silicate.

[0043] The modified phosphorus slag powder is composed of phosphorus slag powder, desulfurized gypsum and metakaolin, and the mass fraction of the phosphorus slag powder, desulfurized gypsum and metakaolin is 1:0.4:0.2:0.2.

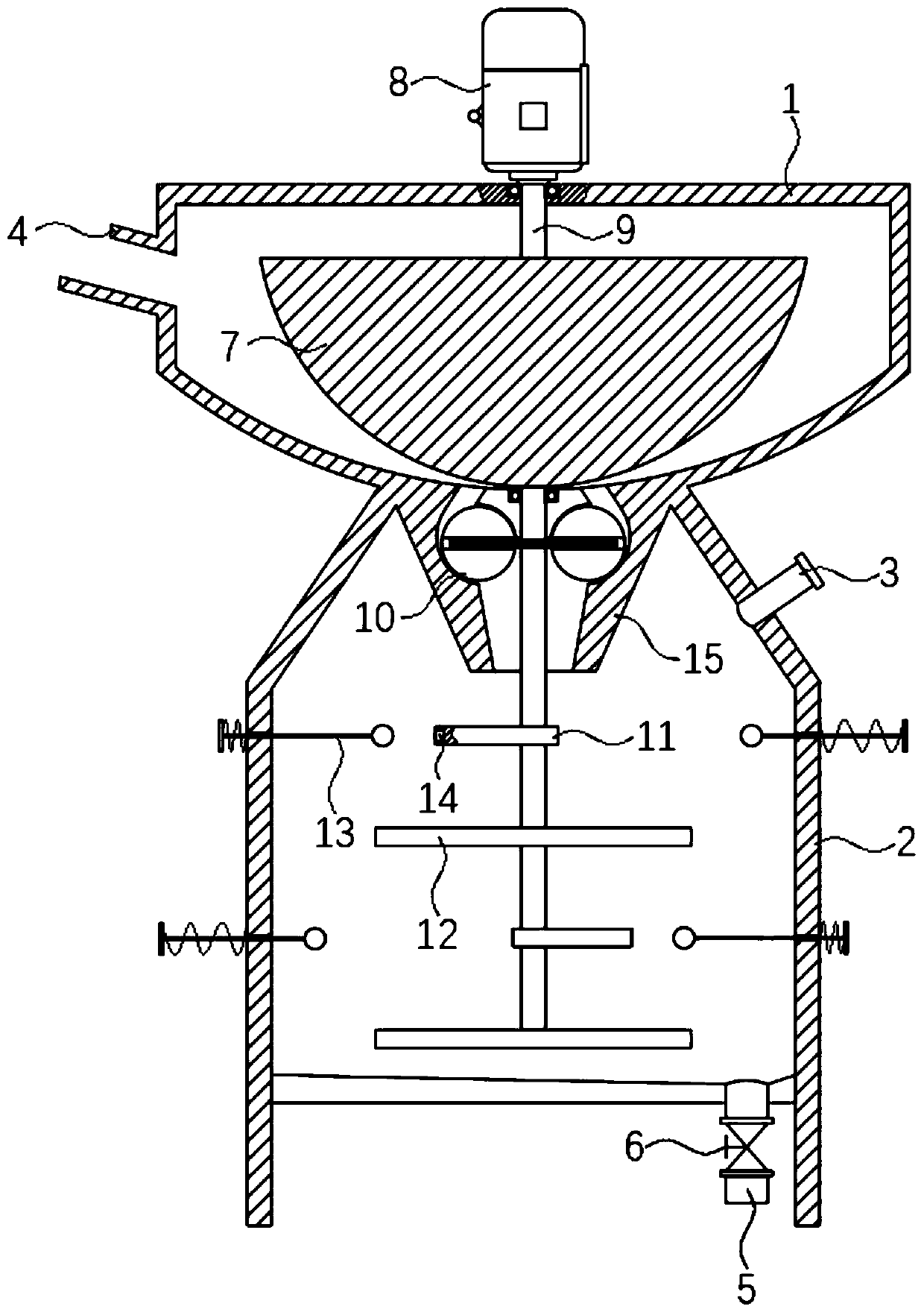

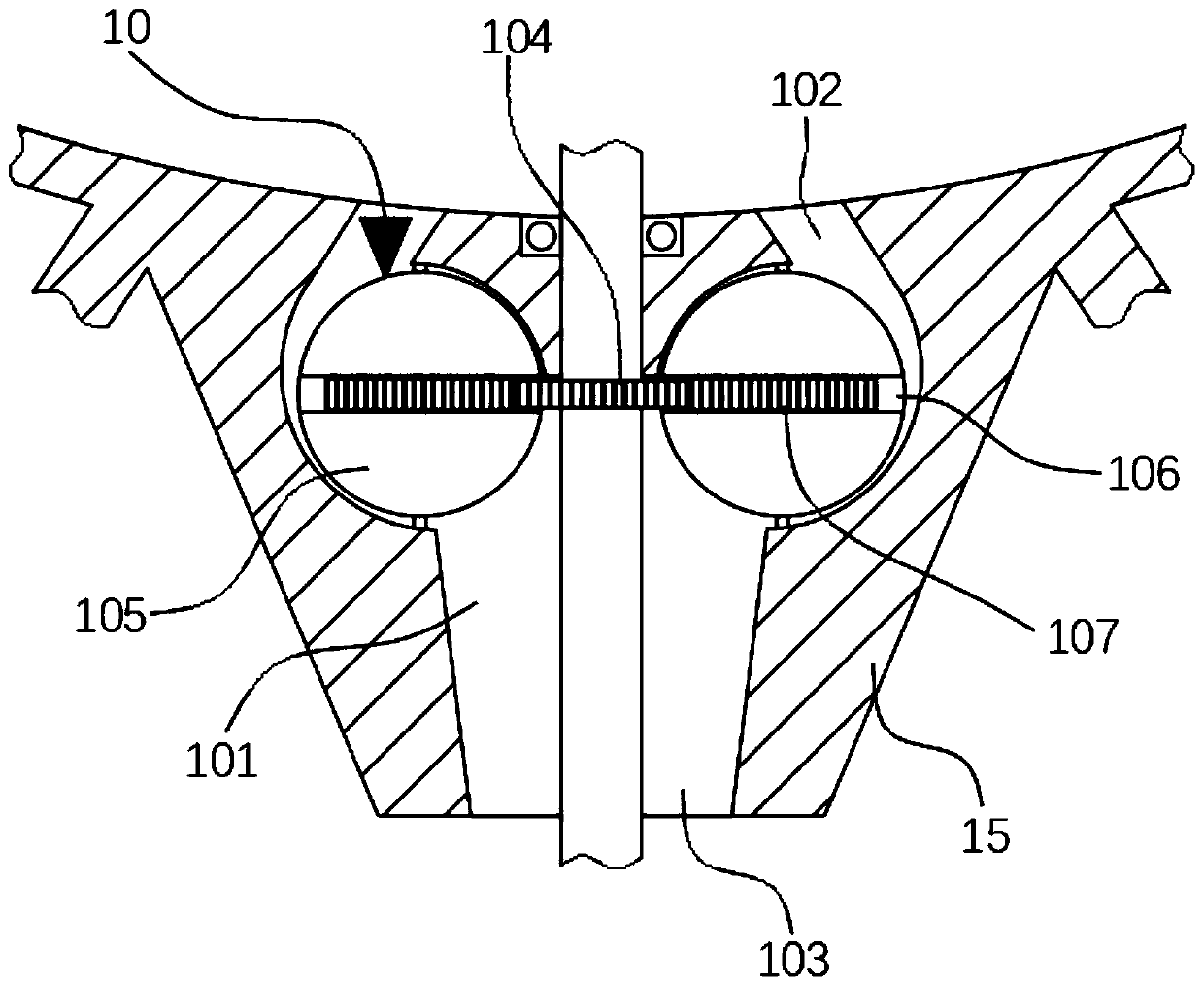

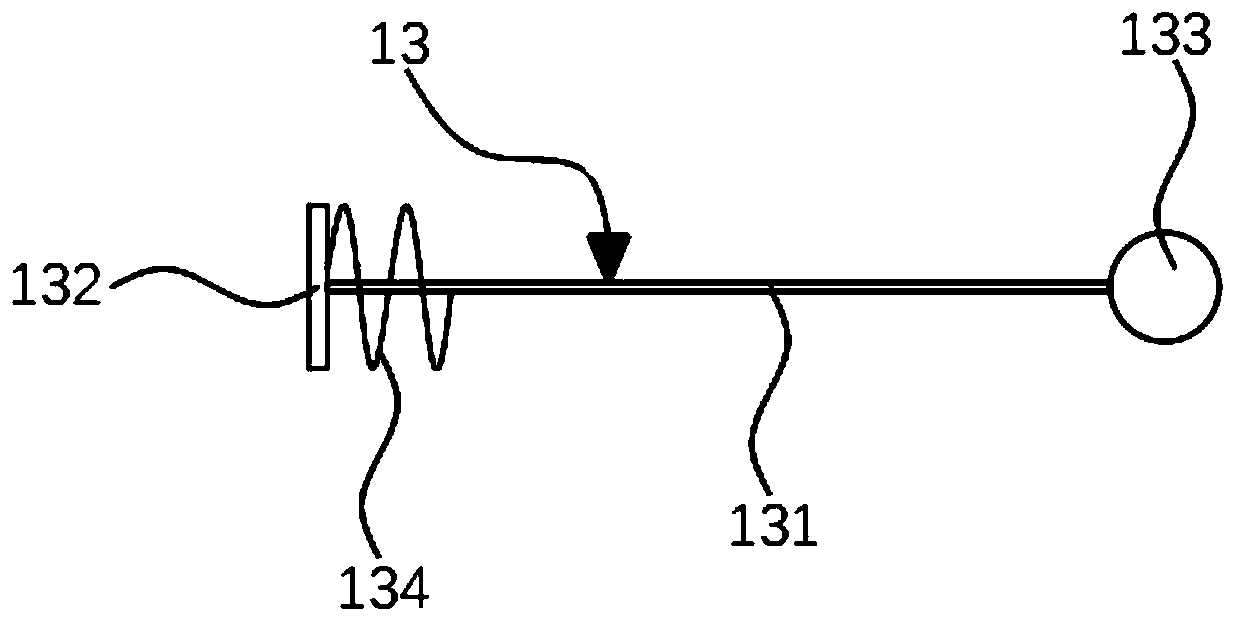

[0044] In above-mentioned embodiment 1 to embodiment 3, all adopt a kind of preparation equipment of phosphorus slag base coagulation, this equipment comprises upper shell 1 and lower shell 2, upper shell 1 and lower shell 2 form a whole together, upper shell 1 The middle shell 15 is fixedly connected with the lower shell 2, the inner space of the upper shell 1, the middle shell 15 and the lower shell 2 is connected, the upper shell 1 is provided with a feed port 4, and the lower shell 2 is connected with a water inlet pipe 3, The bottom of the lower shell 2 is connected with a discharge pipe 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com