Concrete material by using tail sand to displace yellow sand and preparation method thereof

A technology for concrete and tailings, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high extraction rate, low cost, high energy consumption, and achieve simple preparation process, excellent performance, saving The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

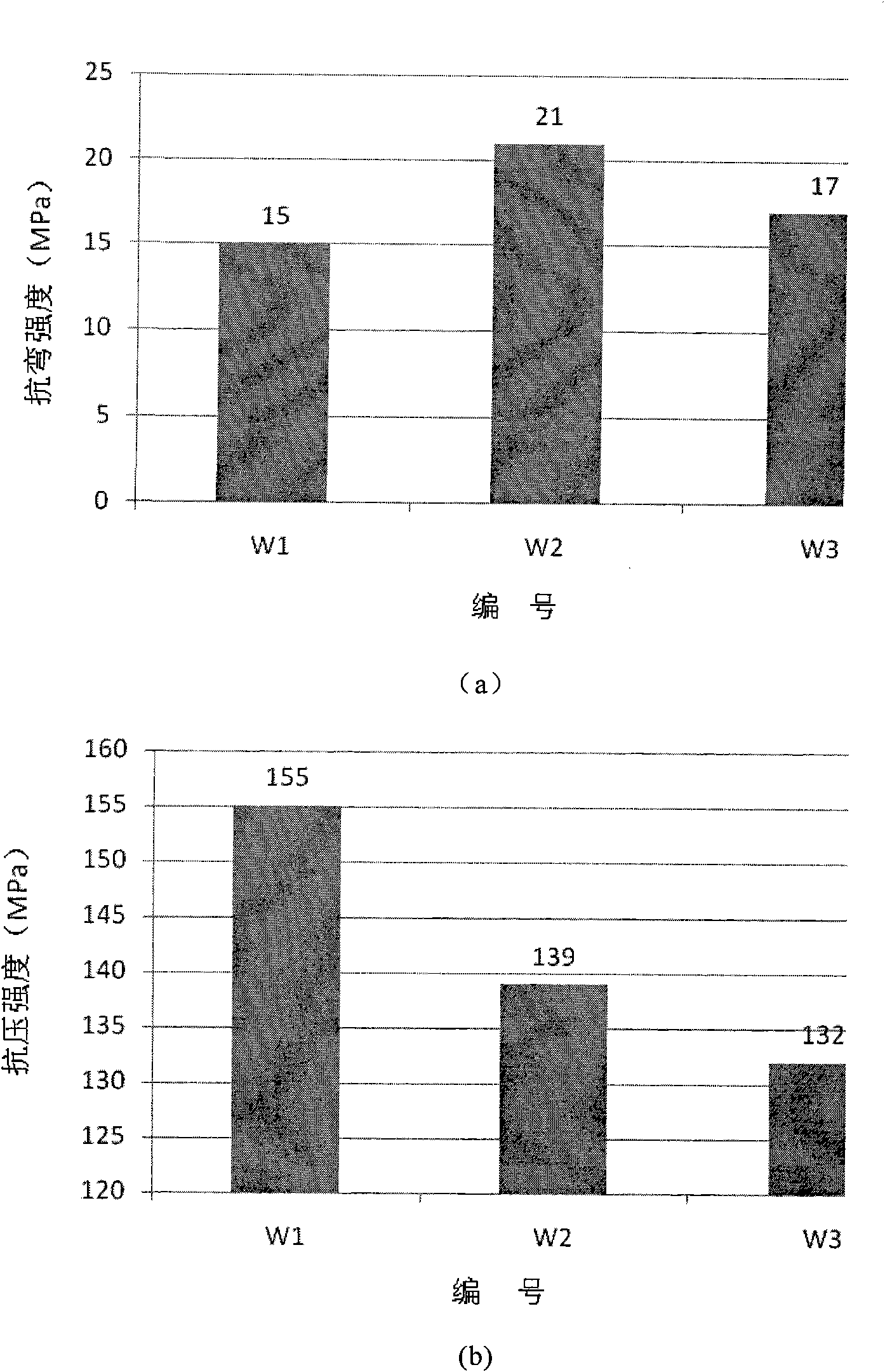

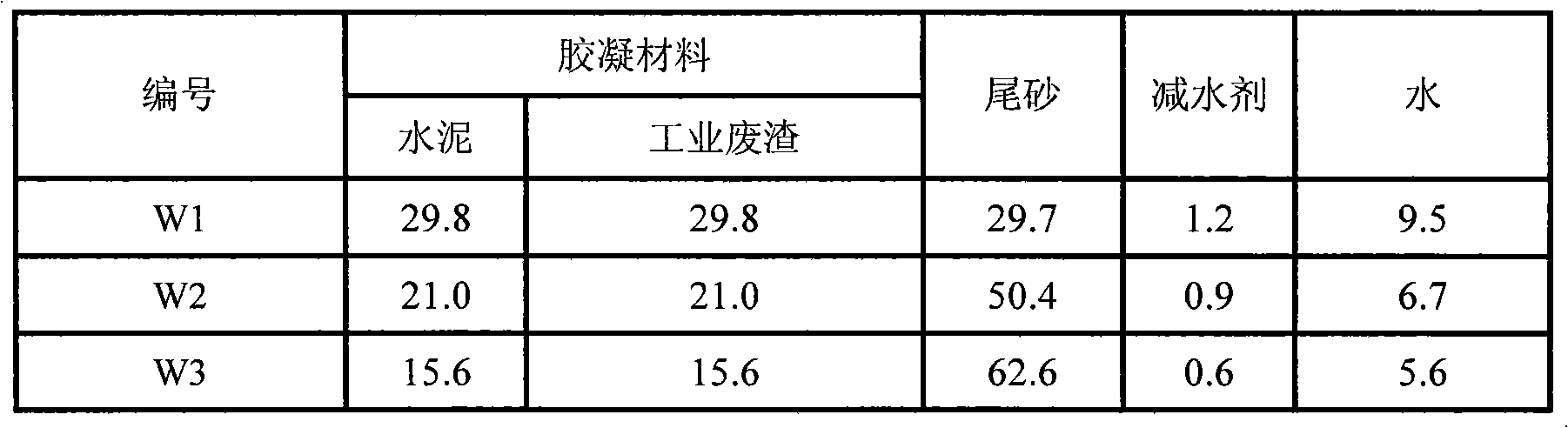

[0031] Weigh the cement, industrial waste and tailings according to the ratio shown in Table 1 and mix them uniformly in the concrete mixer; weigh the admixture and water according to the ratio shown in Table 1, mix them uniformly, and pour them into the uniformly stirred solid raw materials. Continue to stir to obtain a well-stirred concrete mixture; pour the concrete mixture in the mixer into the mold, and vibrate and compact it on the vibrating table; put the concrete material in the mold under standard conditions for 24 hours, wait for After hardening, the formwork was removed, and the prepared concrete material was cured under standard conditions for 7 days, and then cured in hot water at 95°C for 24 hours. After curing, test the flexural and compressive strength of the concrete material, the test results are as follows: figure 1 shown. The tailings in Example 1 are iron ore tailings, the cement is 52.5 Portland cement, the industrial waste residue is a mixture of silica...

Embodiment 2

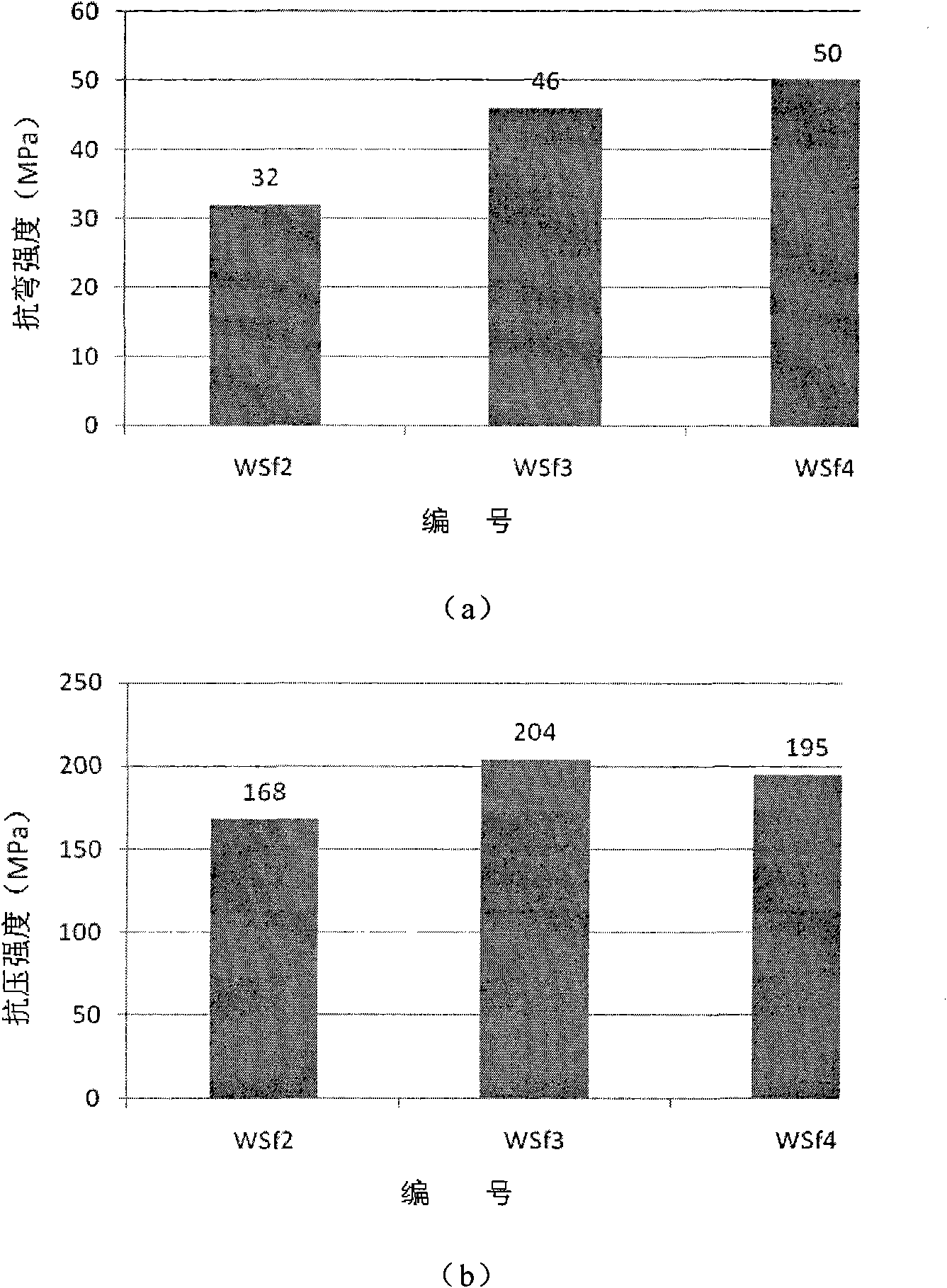

[0035] Weigh the cement, industrial waste residue and tailings according to the ratio shown in Table 2 and mix them evenly in the concrete mixer; weigh the admixture and water according to the ratio shown in Table 2 and mix them evenly, then pour them into the evenly stirred solid raw materials , continue to stir; weigh the steel fibers according to the ratio shown in Table 2, evenly sprinkle them in the mixer, and stir further, so as to obtain a uniformly stirred fiber concrete mixture; pour the fiber concrete mixture in the mixer into the mold , and vibrated on a vibrating table for compaction; the concrete material in the mold was left to stand for 24 hours under standard conditions, and after it hardened, the mold was removed, and the prepared concrete material was cured under standard conditions for 7 days, and then placed at 95°C Cured in hot water for 24 hours. After curing, test the flexural and compressive strength of the fiber reinforced concrete material, the test r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com