Method and apparatus for modifying pozzolanic activity of mineral material

A technology of volcanic ash activity and mineral materials, which is applied in the fields of climate sustainability, solid waste management, sustainable waste treatment, etc. The effect of reducing dosage and increasing pozzolanic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

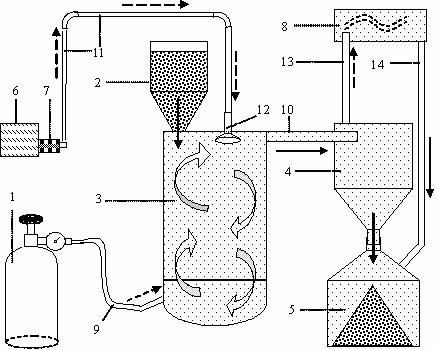

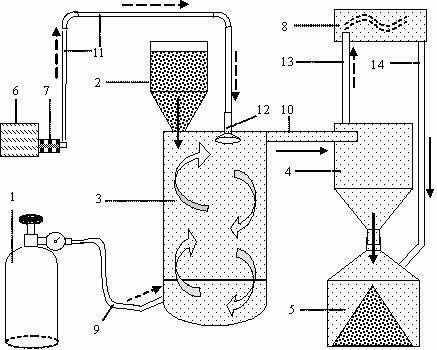

[0023] Embodiment 1, the steps are as follows:

[0024] (1) Pack a class II fly ash material of a power plant in the feed bin 2;

[0025] (2) Put the aqueous solution of calcium hydroxide modifier with a mass concentration of 16% into the heating container 6, open the atomizer 7, and make the aqueous calcium hydroxide solution enter the fluidization through the water pipe 11 and the nozzle 12 after atomization treatment In bed container 3;

[0026] (3) Open the valve of the nitrogen cylinder to allow nitrogen to enter the fluidized bed container 3 through the air pipe 9;

[0027] (4) Open the valve of the feed bin 2 to allow the fly ash to enter the fluidized bed container 3, and adjust the valve of the feed bin and the nitrogen cylinder valve so that the fly ash is suspended in the fluidized bed container 3;

[0028] (5) After the suspended fly ash is fully mixed with atomized particles containing calcium hydroxide in the fluidized bed container 3, it enters the decompressi...

Embodiment 2

[0036] Embodiment 2, the steps are as follows:

[0037] (1) A kind of S95 grade ore powder is installed in the feed bin 2;

[0038] (2) Put the sodium hydroxide aqueous solution with a mass concentration of 20% into the modifier container 6, open the atomizer 7, and make the sodium hydroxide solution enter the fluidized bed container through the water pipe 11 and the nozzle 12 after atomization treatment 3 middle;

[0039] (3) Open the outlet valve of the air compressor, so that the air enters the fluidized bed container 3 through the air pipe 9;

[0040] (4) Open the valve of the feeding bin 2 to make the mineral powder enter the fluidized bed container 3, adjust the valve of the feeding bin and the outlet valve of the air compressor, so that the mineral powder is suspended in the fluidized bed container 3;

[0041] (5) After the suspended mineral powder is fully mixed with the atomized sodium hydroxide solution particles in the fluidized bed container 3, it enters the deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com