Efficient activating agent for waste copper tailings and preparation method thereof

An activator and high-efficiency technology, applied in the field of high-efficiency activators for waste copper tailings slag powder, can solve the problems of low pozzolan ash activity, achieve the effects of reducing concrete prices, protecting mineral admixture resources, and excellent excitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

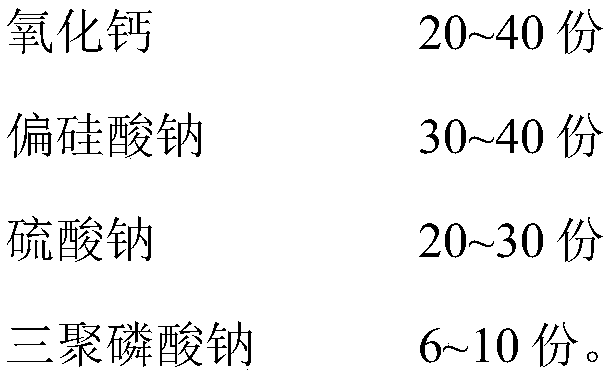

[0034] A high-efficiency activator for waste copper tailings slag powder, which is composed of the following components by weight:

[0035]

[0036] Its preparation method is as follows:

[0037] Mix calcium oxide, sodium metasilicate, sodium sulfate and sodium tripolyphosphate uniformly according to the above weight ratio to form a mixture; heat the obtained mixture in an oven at a temperature of 100°C for 6 hours; dry the heated mixture for another 6 hours Finally, grind until the specific surface area is greater than 300m 2 / kg, that is to obtain a high-efficiency activator for waste copper tailings slag powder.

[0038] The calcium oxide is chemically pure, its CaO content is ≥ 90%, and its relative density is 3.32-3.35g / cm 3; Described sodium metasilicate is chemically pure, and its Na 2 SiO 3 Content ≥ 90%, relative density 1.05 ~ 1.35g / cm 3 ; Described sodium sulfate is chemically pure, and its Na 2 SO 4 Content ≥ 90%, relative density 1.667g / cm 3 ; Described...

Embodiment 2

[0040] A high-efficiency activator for waste copper tailings slag powder, which is composed of the following components by weight:

[0041]

[0042] Its preparation method is as follows:

[0043] Mix calcium oxide, sodium metasilicate, sodium sulfate and sodium tripolyphosphate uniformly according to the above weight ratio to form a mixture; heat the obtained mixture in an oven at a temperature of 90°C for 6 hours; dry the heated mixture for another 6 hours Finally, grind until the specific surface area is greater than 300m 2 / kg, that is to obtain a high-efficiency activator for waste copper tailings slag powder.

[0044] The calcium oxide is chemically pure, its CaO content is ≥ 90%, and its relative density is 3.32-3.35g / cm 3 ; Described sodium metasilicate is chemically pure, and its Na 2 SiO 3 Content ≥ 90%, relative density 1.05 ~ 1.35g / cm 3 ; Described sodium sulfate is chemically pure, and its Na 2 SO 4 Content ≥ 90%, relative density 1.667g / cm 3 ; Described...

Embodiment 3

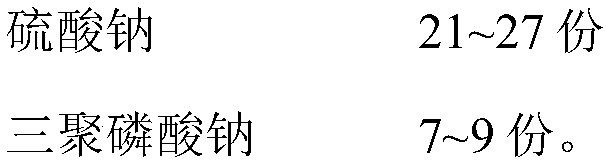

[0046] A high-efficiency activator for waste copper tailings slag powder, which is composed of the following components by weight:

[0047]

[0048] Its preparation method is as follows:

[0049] Mix calcium oxide, sodium metasilicate, sodium sulfate and sodium tripolyphosphate uniformly according to the above weight ratio to form a mixture; heat the obtained mixture in an oven at a temperature of 110°C for 4 hours; dry the heated mixture for another 6 hours Finally, grind until the specific surface area is greater than 300m 2 / kg, that is to obtain a high-efficiency activator for waste copper tailings slag powder.

[0050] The calcium oxide is chemically pure, its CaO content is ≥ 90%, and its relative density is 3.32-3.35g / cm 3 ; Described sodium metasilicate is chemically pure, and its Na 2 SiO 3 Content ≥ 90%, relative density 1.05 ~ 1.35g / cm 3 ; Described sodium sulfate is chemically pure, and its Na 2 SO 4 Content ≥ 90%, relative density 1.667g / cm 3 ; Describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com