Low cementitious material self-compacting concrete

A self-compacting concrete and low-rubber technology, applied in the field of self-compacting concrete, can solve the problems of tailings being discharged into rivers, valleys, lowlands, occupying farmland, forest land, polluting water, soil and atmosphere, etc., so as to improve appearance quality and reduce cementation. The amount of material and the effect of improving the pulp-solid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

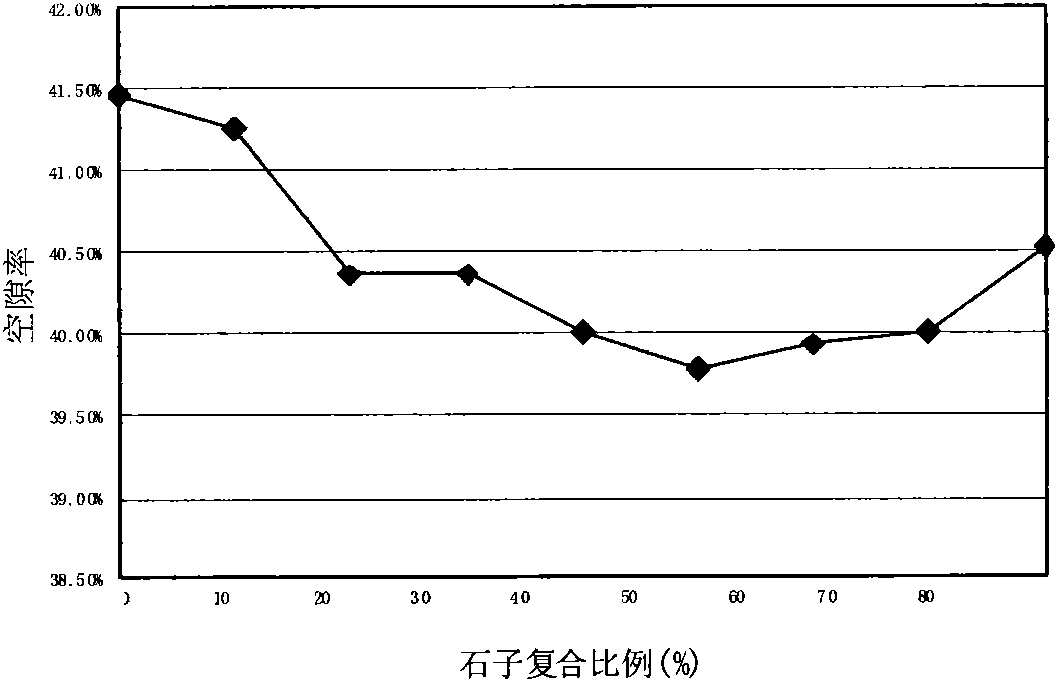

[0025] Due to the production equipment, the currently commonly used 5-25mm machine crushed stone gradation generally fails to meet the standard requirements. There are obviously more large particles above 16mm, the void ratio is too large, and the covering coefficient of concrete is small, resulting in concrete and easy Poor sex. Smaller particle size stones are used to compound with currently commonly used 5-25mm stones to improve the gradation of coarse aggregates. When the compounding ratio reaches about 50%, the void ratio of aggregates is the smallest. The relationship between compound ratio and porosity is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com