Preparation method of waste incineration power plant slag concrete

A technology of waste incineration and concrete, which is applied to the preparation of concrete and the preparation of slag concrete for waste incineration power generation, can solve the problem that the waste slag concrete cannot be fully mixed, the water resistance and compressive strength of concrete are different, and the waste slag and ordinary slag are not considered. The problem of different water absorption of concrete aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

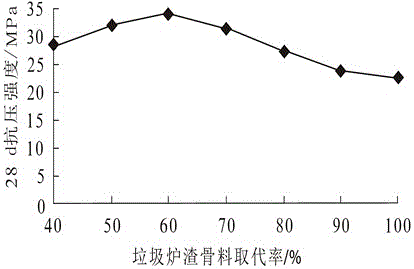

[0087] Example 7 The dosage ratio of each material in concrete is based on the mass of the material required to prepare each cubic concrete, which is: the dosage ratio of each material in the concrete, and is calculated as: garbage 400kg of incineration power plant slag, 300kg of cement, 150kg of magnetized water, 260kg of sand, 1300kg of graded gravel with a particle size of 10-20mm, 3.3kg of water reducing agent, 20kg of GCY activator and 4kg of acrylic resin; the preparation method is as follows:

[0088] (1) Slag pretreatment: The slag discharged from the waste incineration boiler of the waste incineration power plant is washed by a hydrolysis tank to remove soluble salts, and then crushed and screened, magnetically separated, buoyantly sorted, and sieved to obtain a particle size of 3~ 5mm, the apparent density is 1996kg / m 3 waste slag coarse aggregate;

[0089] (2) Preparation of magnetized water: Use a magnetizer to magnetize tap water in advance to obtain magnetized ...

Embodiment 8

[0091] Embodiment 8 The dosage ratio of each material in the concrete is based on the mass of the material required to prepare each cubic concrete, which is: 250kg of incineration power plant slag, 550kg of cement, 200kg of magnetized water, 220kg of sand, 1100kg of graded gravel with a particle size of 10-20mm, 4kg of water reducing agent, 15kg of GCY activator and 4kg of acrylic resin; the preparation method is as follows:

[0092] (1) Slag pretreatment: The slag discharged from the waste incineration boiler of the waste incineration power plant is washed by a hydrolysis tank to remove soluble salts, and then crushed and screened, magnetically separated, buoyantly sorted, and sieved to obtain a particle size of 3~ 5mm, the apparent density is 1996kg / m 3 waste slag coarse aggregate;

[0093] (2) Preparation of magnetized water: Use a magnetizer to magnetize tap water in advance to obtain magnetized water for use as a spare;

[0094] (3) Concrete preparation: first add 35% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

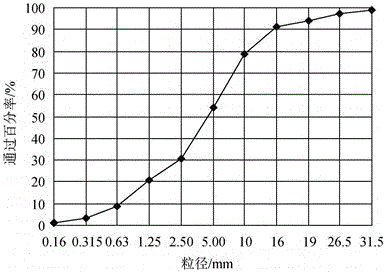

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com