Mass eco-concrete expansive agent and preparation method thereof

A technology of mass concrete and expansion agent, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as the gap in expansion process, achieve controllable expansion amount, simple and easy preparation process, and expansion Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

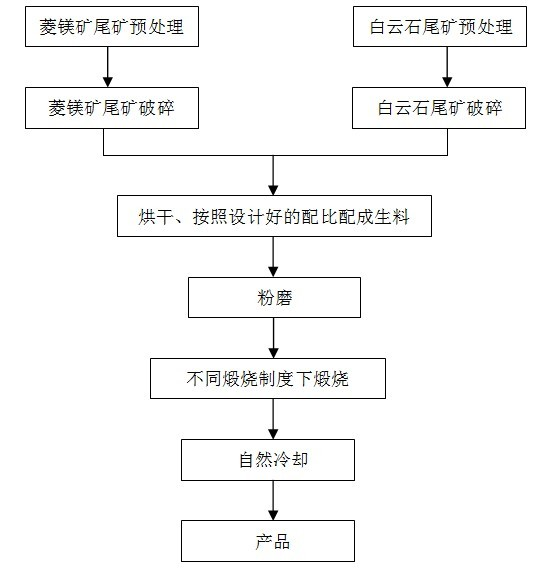

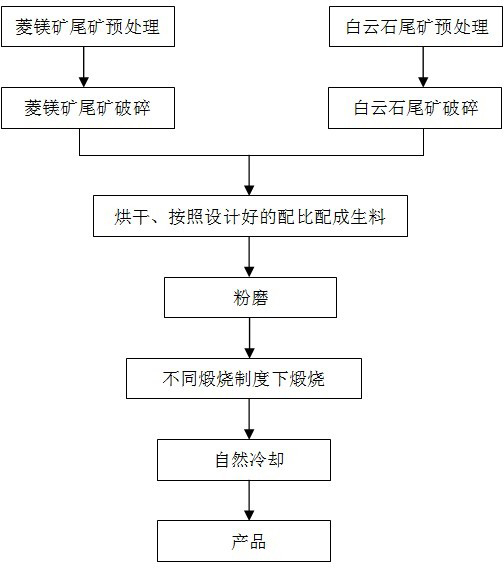

Method used

Image

Examples

Embodiment 1

[0026] (1) A new type of ecological large-volume concrete expansion agent includes the following components in parts by weight:

[0027] Component 1: magnesite tailings, 100 parts;

[0028] Component 2: dolomite tailings, 0 parts;

[0029] (2) Preparation of a new type of ecological mass concrete expansion agent

[0030] 1) Pass the ore through a 0.63mm square hole sieve and perform pretreatment, after crushing, grind it and pass it through an 80μm square hole sieve, and the sieve residue is less than 10%;

[0031] 2) Mix magnesite tailings and dolomite tailings in a ratio of 1:0 to make a raw meal, mix well, dry at 110°C for 1 hour, and then calcine the powder at high temperature;

[0032] 3) The calcination temperature is set at 950°C, the calcination time is 119min, the holding time is 90min, and the heating rate is 8°C / min.

[0033] 4) After cooling in the air, a new type of ecological large-volume concrete expansion agent A can be obtained after screening.

[0034]

Embodiment 2

[0036] (1) A new type of ecological large-volume concrete expansion agent includes the following components in parts by weight:

[0037] Component 1: magnesite tailings, 80 parts;

[0038] Component 2: dolomite tailings, 20 parts;

[0039] (2) Preparation of a new type of ecological mass concrete expansion agent

[0040] 1) Pass the ore through a 0.63mm square hole sieve and perform pretreatment, after crushing, grind it and pass it through an 80μm square hole sieve, and the sieve residue is less than 10%;

[0041] 2) Mix magnesite tailings and dolomite tailings into raw material according to the ratio of 4:1, mix evenly, dry at 110°C for 1 hour, and then calcine the powder at high temperature;

[0042] 3) The calcination temperature is set at 1050°C, the calcination time is 117min, the holding time is 90min, and the heating rate is 9°C / min.

[0043] 4) After cooling in the air, a new type of ecological large-volume concrete expansion agent B can be obtained through sieving...

Embodiment 3

[0046] (1) A new type of ecological large-volume concrete expansion agent includes the following components in parts by weight:

[0047] Component 1: magnesite tailings, 25 parts;

[0048] Component 2: dolomite tailings, 75 parts;

[0049] (2) Preparation of a new type of ecological mass concrete expansion agent

[0050] 1) Pass the ore through a 0.63mm square hole sieve and perform pretreatment. After crushing and grinding, pass through an 80μm square hole sieve, and the sieve residue is less than 10%;

[0051] 2) Mix magnesite tailings and dolomite tailings into raw material according to the ratio of 1:3, mix evenly, dry at 120°C for 1 hour, and then calcine the powder at high temperature;

[0052] 3) The calcination temperature is set at 1150°C, the calcination time is 115min, the holding time is 90min, and the heating rate is 10°C / min.

[0053] 4) After cooling in the air, a new type of ecological large-volume concrete expansion agent C can be obtained through sieving. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com