A construction method of large-volume non-cooling tubular concrete

A construction method, no cooling technology, used in thermometers, thermometer applications, instruments, etc., to achieve excellent crack resistance, good volume stability, and the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

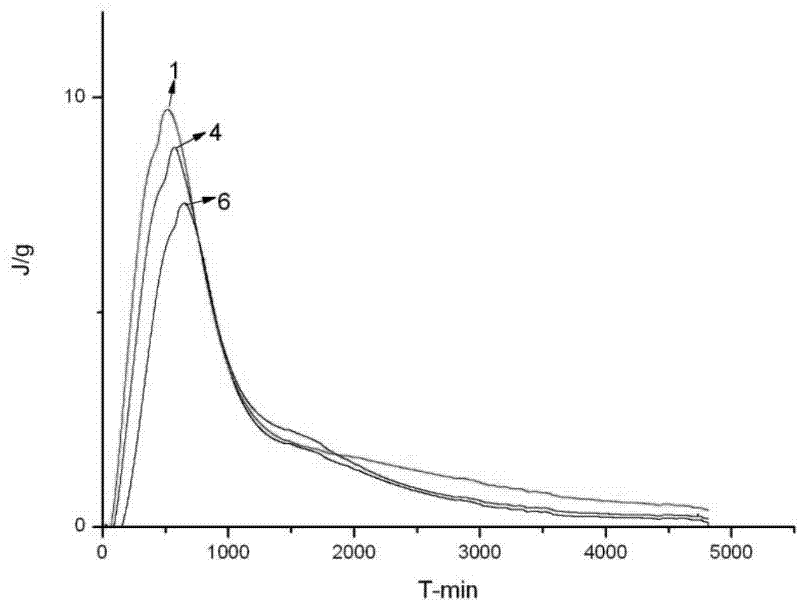

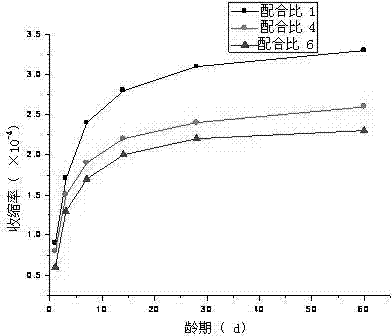

[0040] A: Preparation of raw materials: In order to make the early strength of the concrete body high, the fineness of the cement should be less than 0.04mm; Cement: In large-volume concrete, the temperature difference is mainly caused by the heat release of cement hydration, therefore, low heat release should be selected Since the fineness of cement will affect the heat release rate of the heat of hydration, the fineness of the cement should be appropriately reduced without affecting the activity of the cement. Cement: Conch brand P.042.5 cement (ordinary silicic acid Salt).

[0041] Fly ash, water demand ratio 98%; admixture. Fly ash can improve the workability of concrete, greatly improve the working performance and durability of concrete, and replace cement can reduce the heat of hydration, but when the amount of fly ash is large, it will have a greater impact on the ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com