Full-process intelligent temperature control system and method for large-volume concrete

A large-volume concrete and temperature control system technology, applied in the direction of temperature control, control/regulation system, comprehensive factory control, etc., can solve the problems of inadequate measures and management, large cooling range, unsystematic, etc., to prevent large-volume concrete Cracks, the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

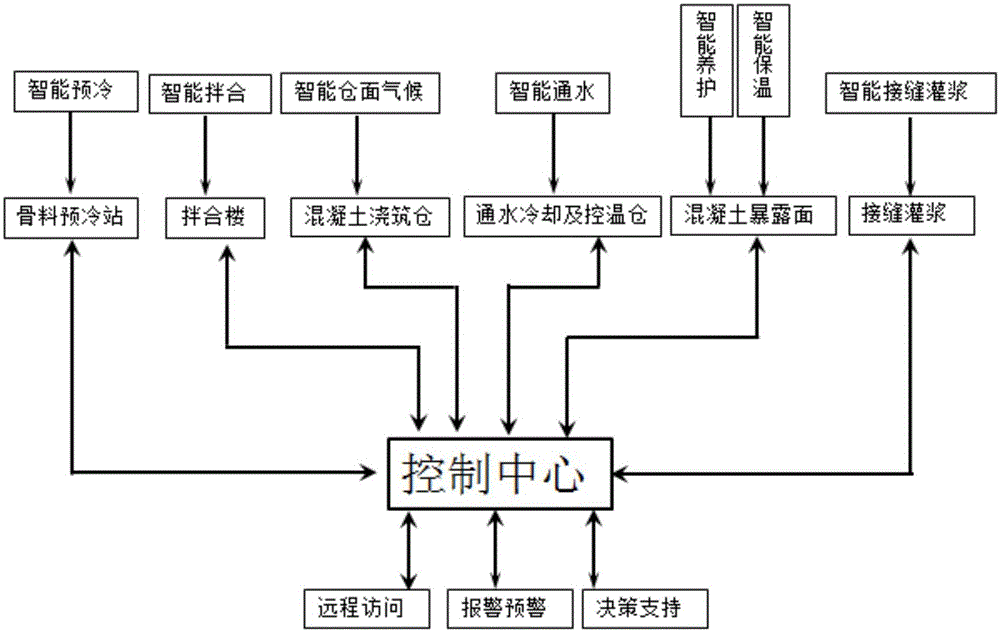

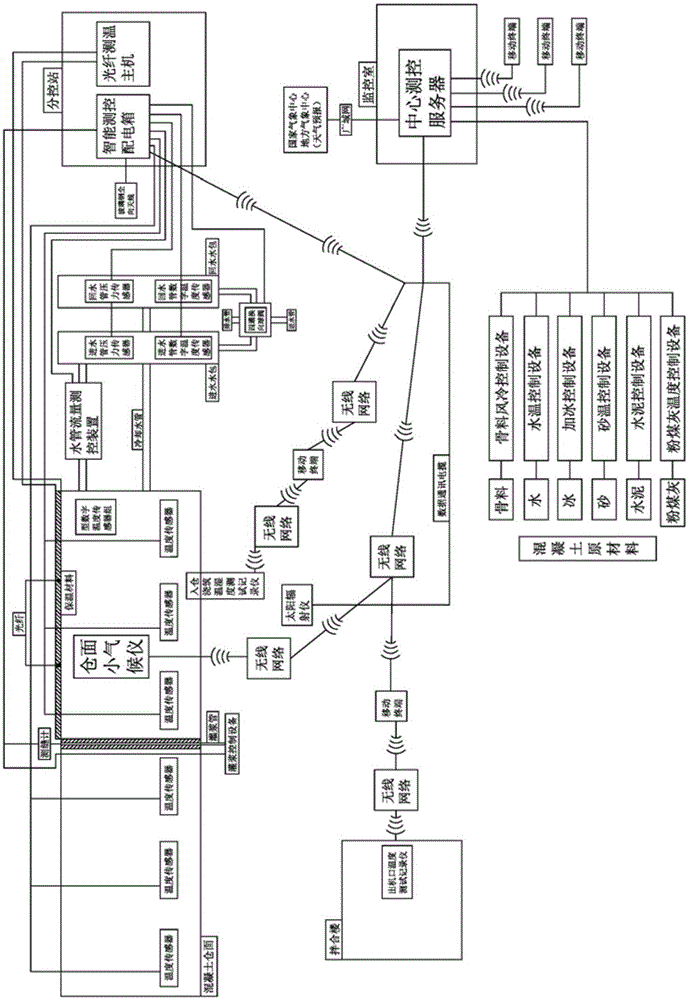

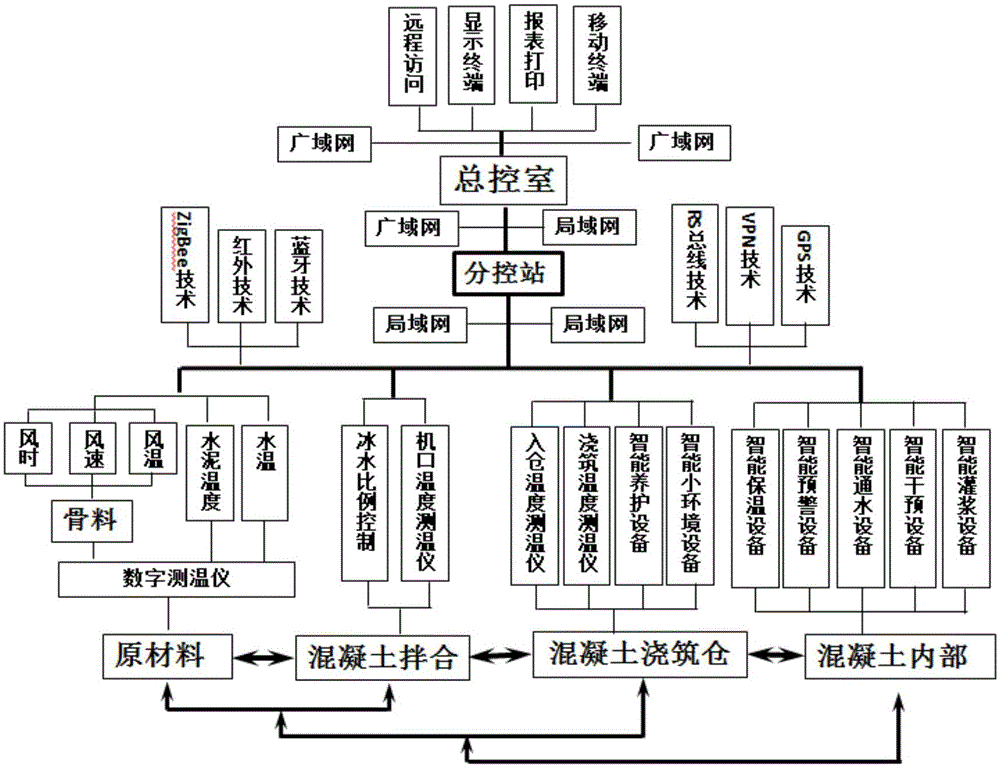

[0031] Such as figure 1 As shown, this intelligent temperature control system for the whole process of large-volume concrete includes an intelligent pre-cooling temperature control unit for aggregates, an intelligent mixing temperature control unit for concrete, an intelligent small environment unit in the concrete pouring silo, and an intelligent water cooling unit for concrete. , Concrete exposed surface intelligent maintenance unit, concrete exposed surface intelligent insulation unit, intelligent joint grouting unit, control center;

[0032] Aggregate intelligent pre-cooling temperature control unit, used for air cooling and temperature control of aggregate;

[0033] Concrete intelligent mixing temperature control unit, used to control the temperature of concrete mixing through mixing water temperature control, ice water ratio, cement temperature control, sand temperature control and fly ash temperature control;

[0034] The intelligent small environment unit in the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com