Automatic monitoring method of concrete casting vibrating blank layer

A technology of pouring vibration and automatic monitoring, which is applied in the fields of construction, building structure, and building material processing, and can solve the problems of unavoidable leakage vibration, difficulty in obtaining blank layer coverage time leakage vibration, over vibration, under vibration, single billet Layer vibration quality control is rough and other problems, to avoid the effect of vibration leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

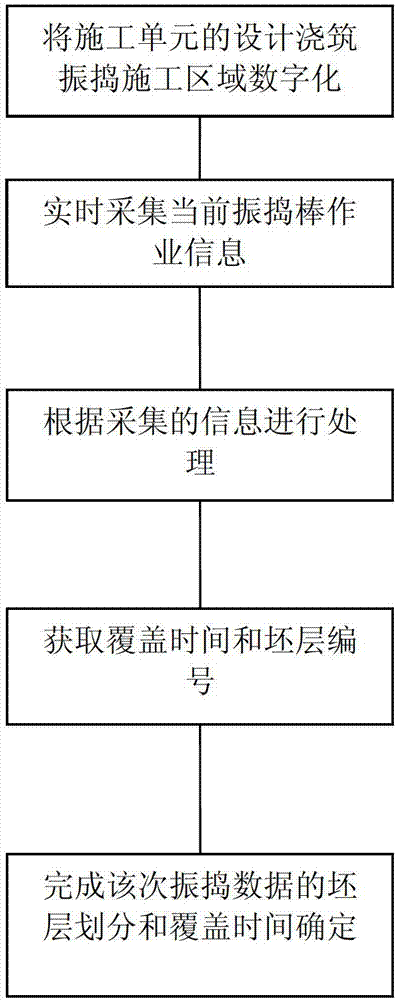

[0021] Such as figure 1 As shown, the main process of this example is to first digitize the design, pouring and vibrating construction area of the construction unit, and then collect the current vibrating bar operation information in real time, and perform calculation and processing based on the collected information to obtain the coverage time and base layer number, so that Complete the layer division and coverage time determination of the vibration data.

[0022] The specific process is:

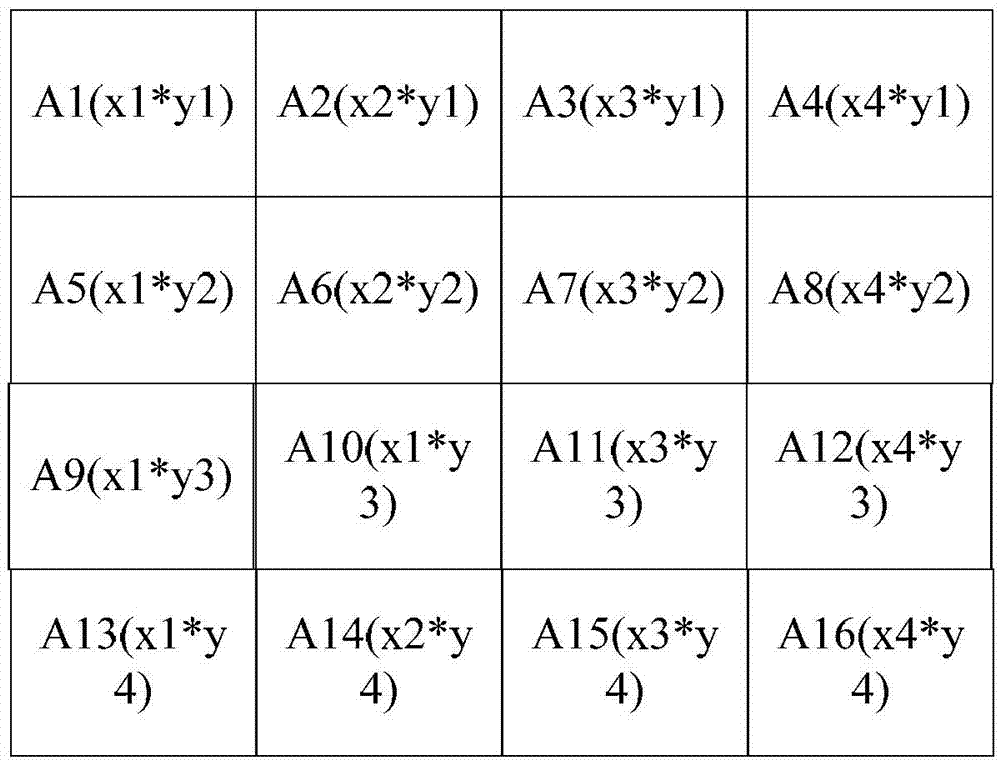

[0023] First, before starting to vibrate, digitize the design pouring and vibrating construction area of the construction unit, divide the area equally according to a certain interval (for example, the influence range of the vibrating rod is 0.75m*0.75m), and obtain the vibrating area lattice A(m*n), such as figure 2 As shown, and given lattice coordinate information (Xa, Ya), this example divides A1 (x1, y1) - A16 (x4, y4) a total of 16 squares with the same area, and at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com