Mass concrete construction method of super-thick foundation

A technology of mass concrete and construction method, applied in the direction of basic structure engineering, building construction, construction, etc., can solve the problem of damage to the bearing capacity, use function and durability of the engineering structure, affecting the frost resistance, impermeability, acceleration, etc. of the structure. Concrete natural aging and other problems, to achieve the effect of shortening the time of heat dissipation, reducing the curing time and improving the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 3200m 3 The outline of the blast furnace foundation is rectangular, with a length of 57m and a width of 42.6m. The base elevation -5.000m to ±0.000 is ordinary C25 concrete, and the total amount of concrete is about 11,000m 3 .

[0048] 1. Construction of water-cooled pipes:

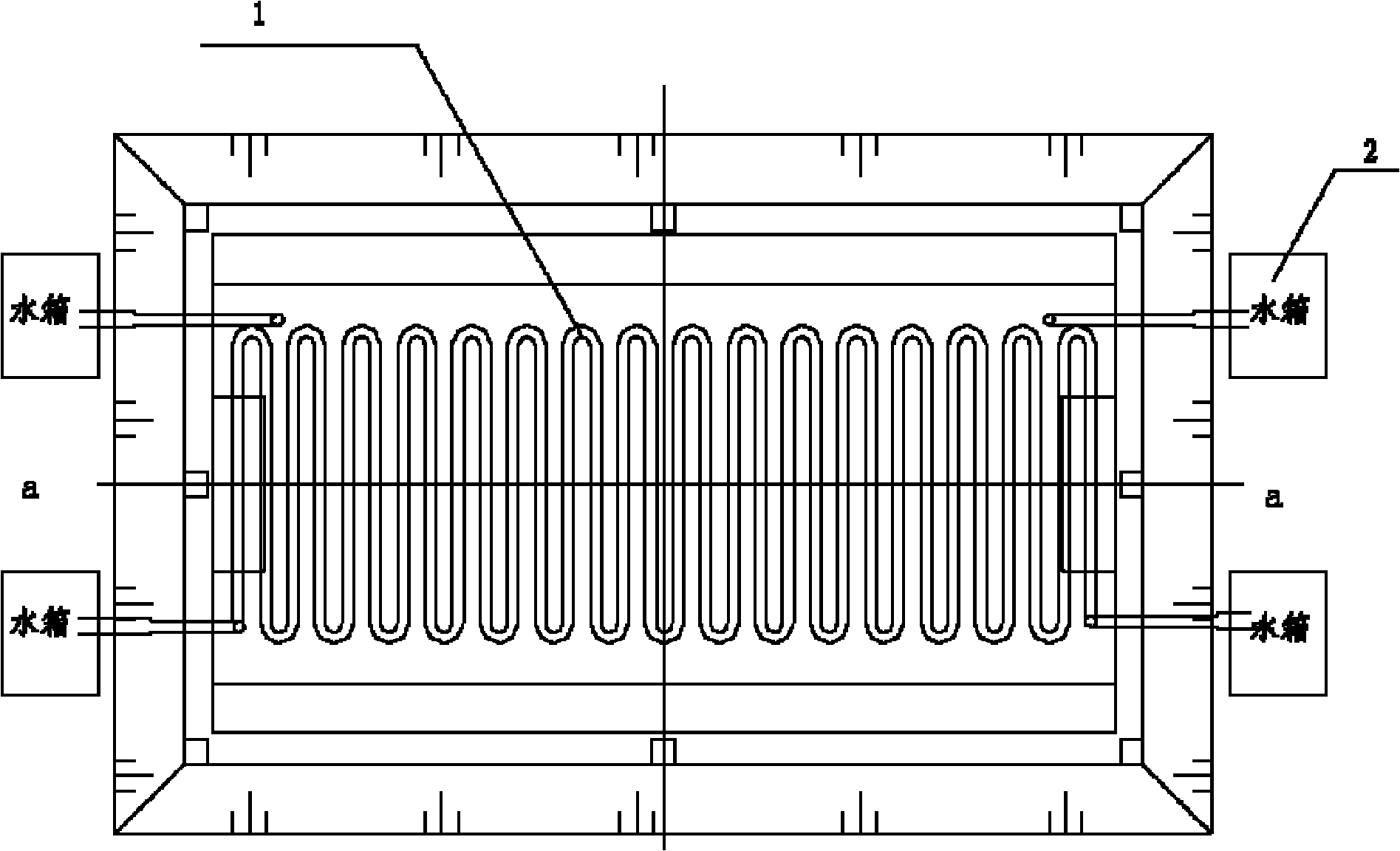

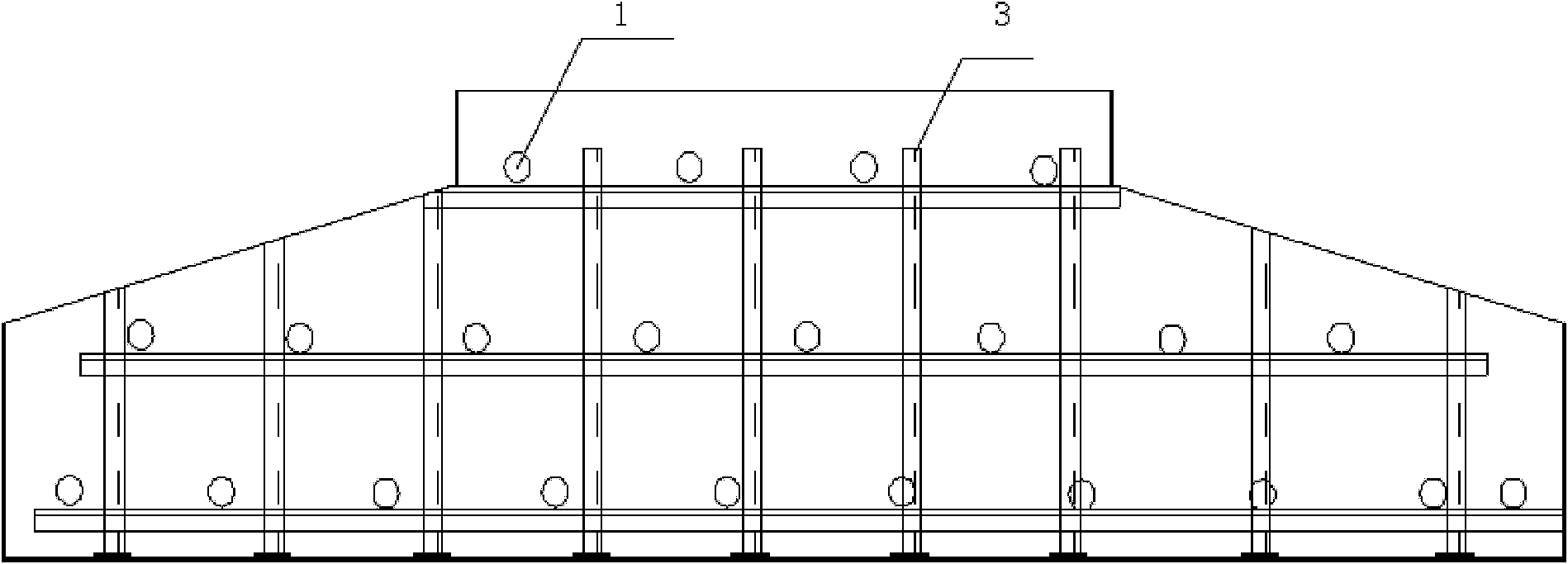

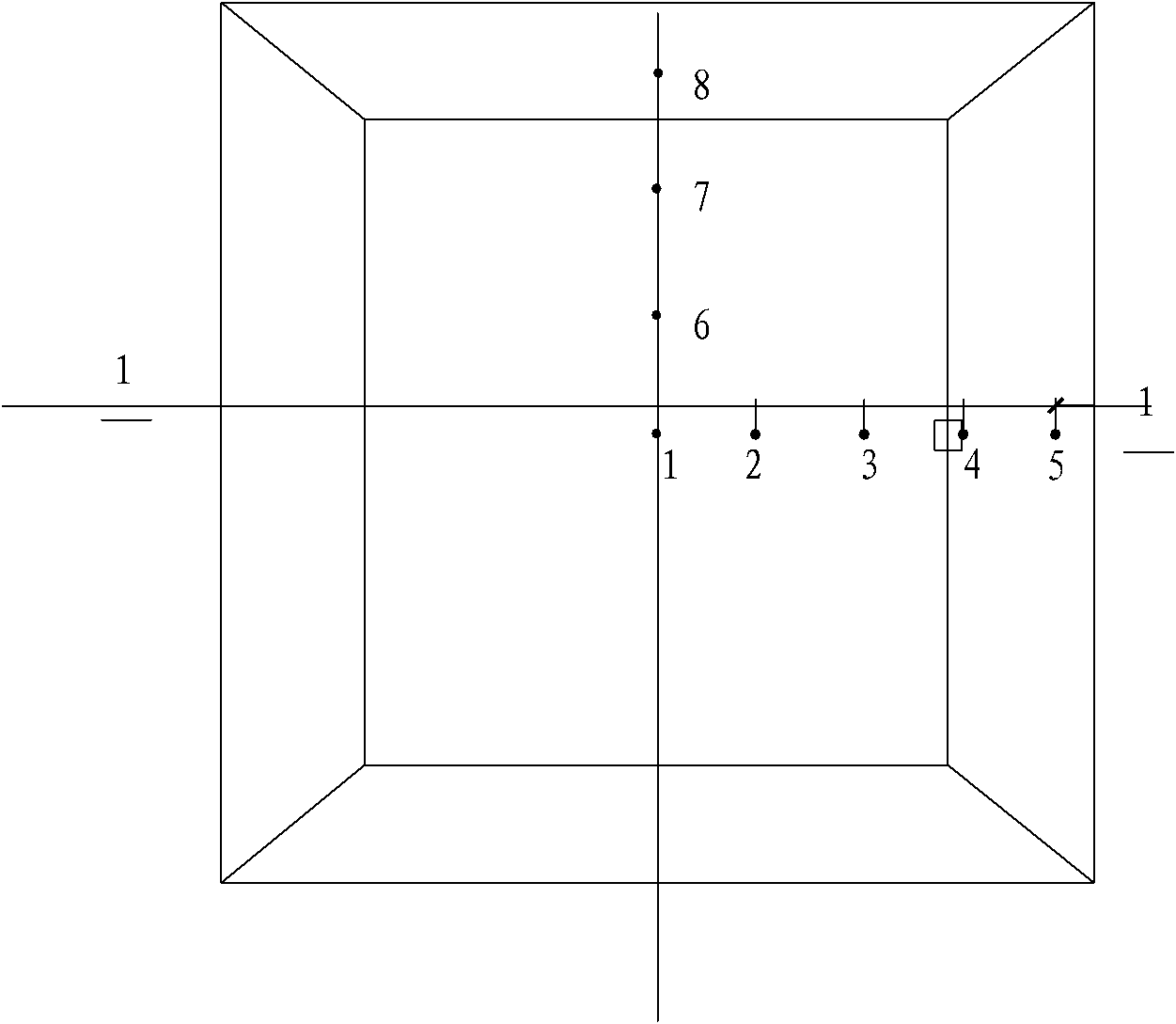

[0049] See Figure 1~2 , after the steel bars on the bottom plate of the blast furnace foundation are bound, the cooling water pipe 1 is constructed on the steel bar fixing frame 3. Within the scope of 53m×38.6m in the foundation, 3 layers of snake-shaped water pipes with a diameter of 48mm×1500mm are pre-buried. The distance between the first layer and the The concrete cushion is 1m, the distance between the second layer and the concrete cushion is 2.5m, and the distance between the third layer and the concrete cushion is 4m. A water leak test is required and repairs to leak points are required.

[0050] 2. Mixing of concrete:

[0051] C25 anti-crack concrete is used, and the mix ratio per ...

Embodiment 11

[0059] Table 1: A mix ratio of C25 anti-crack concrete for ultra-thick, large-volume foundations:

[0060] material name

Embodiment 12

[0062] Table 2: A mix ratio of C25 anti-crack concrete for super-thick, large-volume foundations:

[0063] material name

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com