Temperature-controlled crack prevention construction method for concrete structure

A concrete structure, temperature control crack prevention technology, applied in basic structure engineering, building construction, construction and other directions, can solve the problems of low crack prevention reliability, easy cracking of concrete, poor crack prevention versatility, etc., to improve scientific research level and The effect of technical ability, good crack prevention versatility, and high crack prevention reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

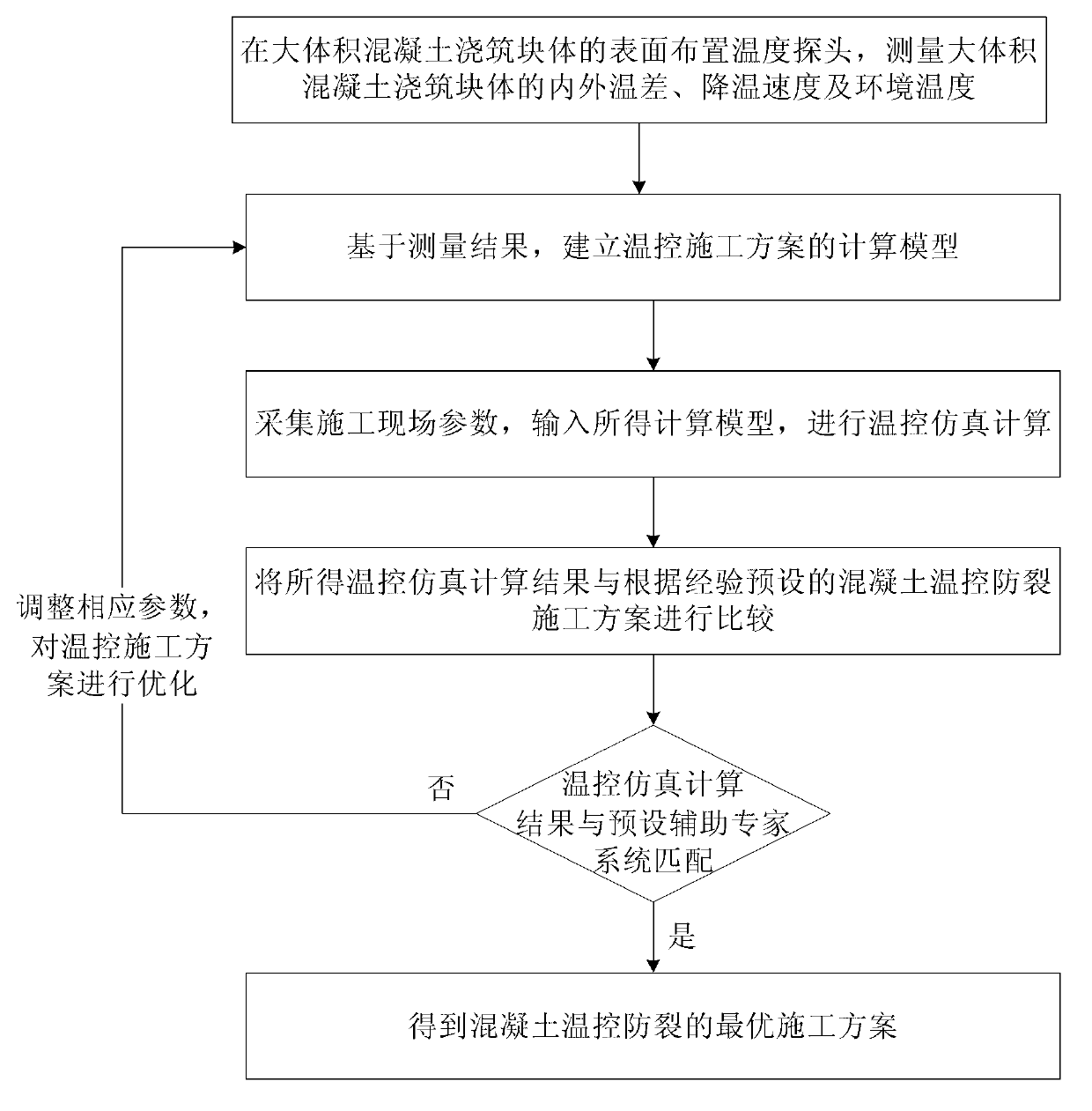

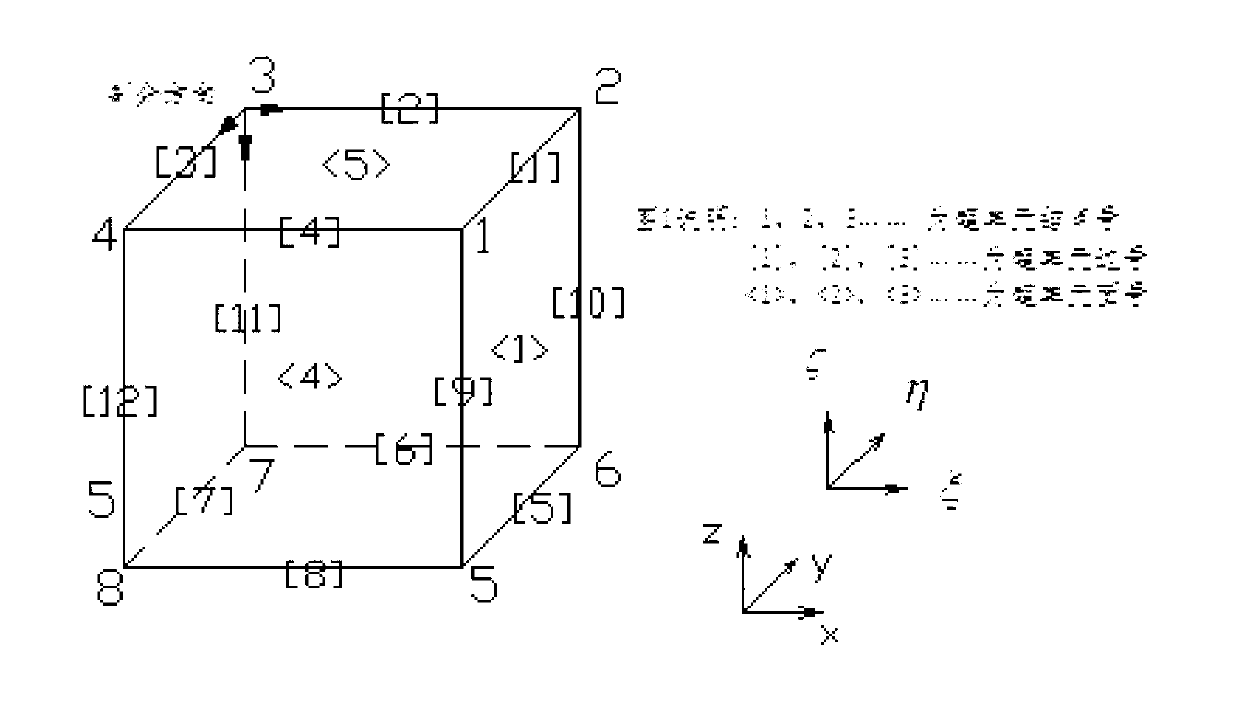

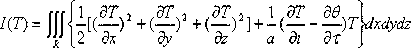

[0048] According to an embodiment of the present invention, a concrete structure temperature control and anti-cracking construction method is provided, that is, a method of using TCAS software to perform simulation calculations on various proposed temperature control schemes of concrete structures (the simulation calculation can simulate concrete climate conditions , pouring temperature control, external heat preservation, joints and blocks, etc.) comparative analysis to optimize economical and effective temperature control and anti-cracking measures to reduce concrete structure cracks and improve the safety of concrete structures. Generally, for the prevention and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com