Hot rolling strip steel double-ring control laminar flow cooling system

A double-loop control and laminar cooling technology, applied in the direction of temperature control, can solve the problems of inability to effectively control the cooling time history and inability to effectively control the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

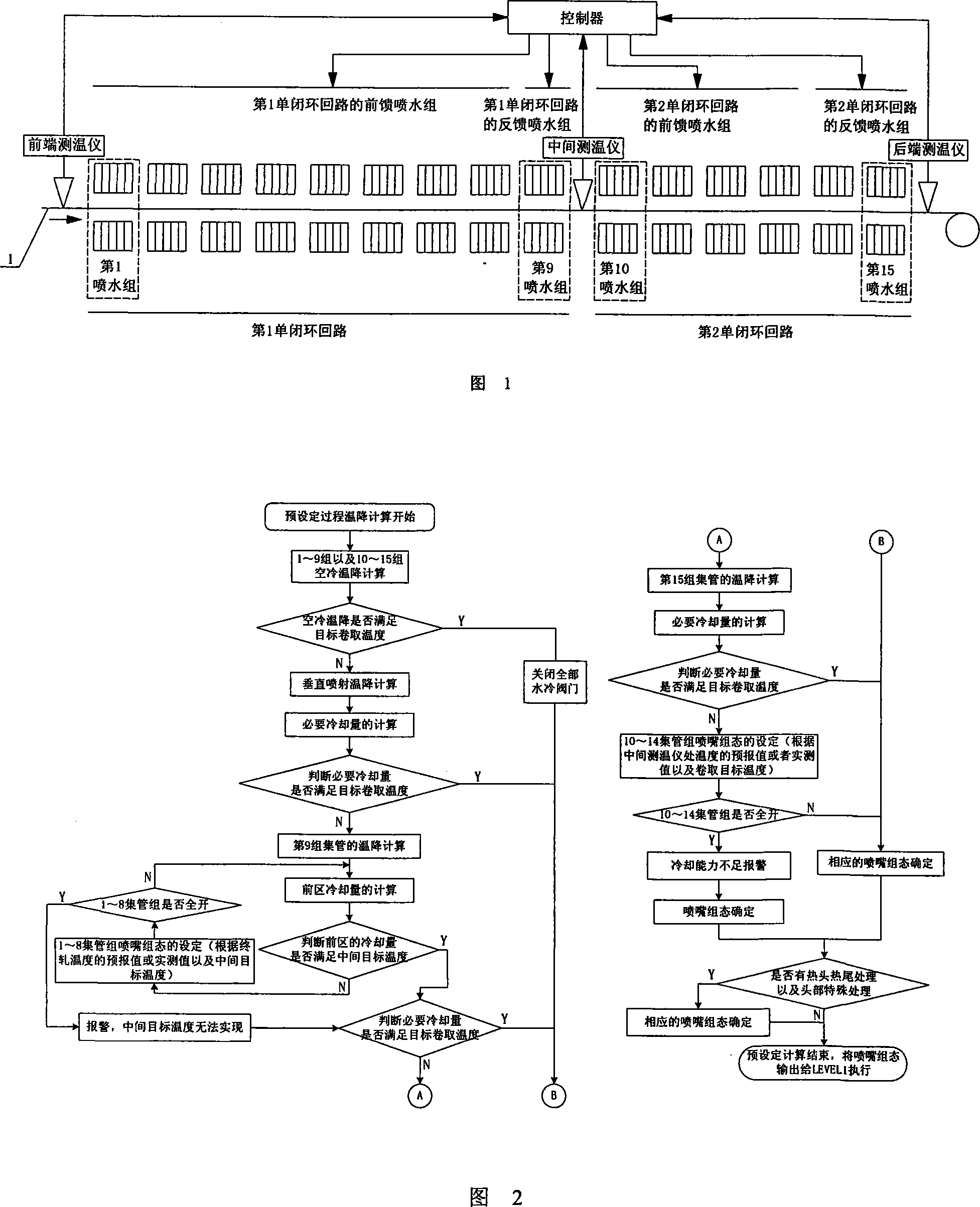

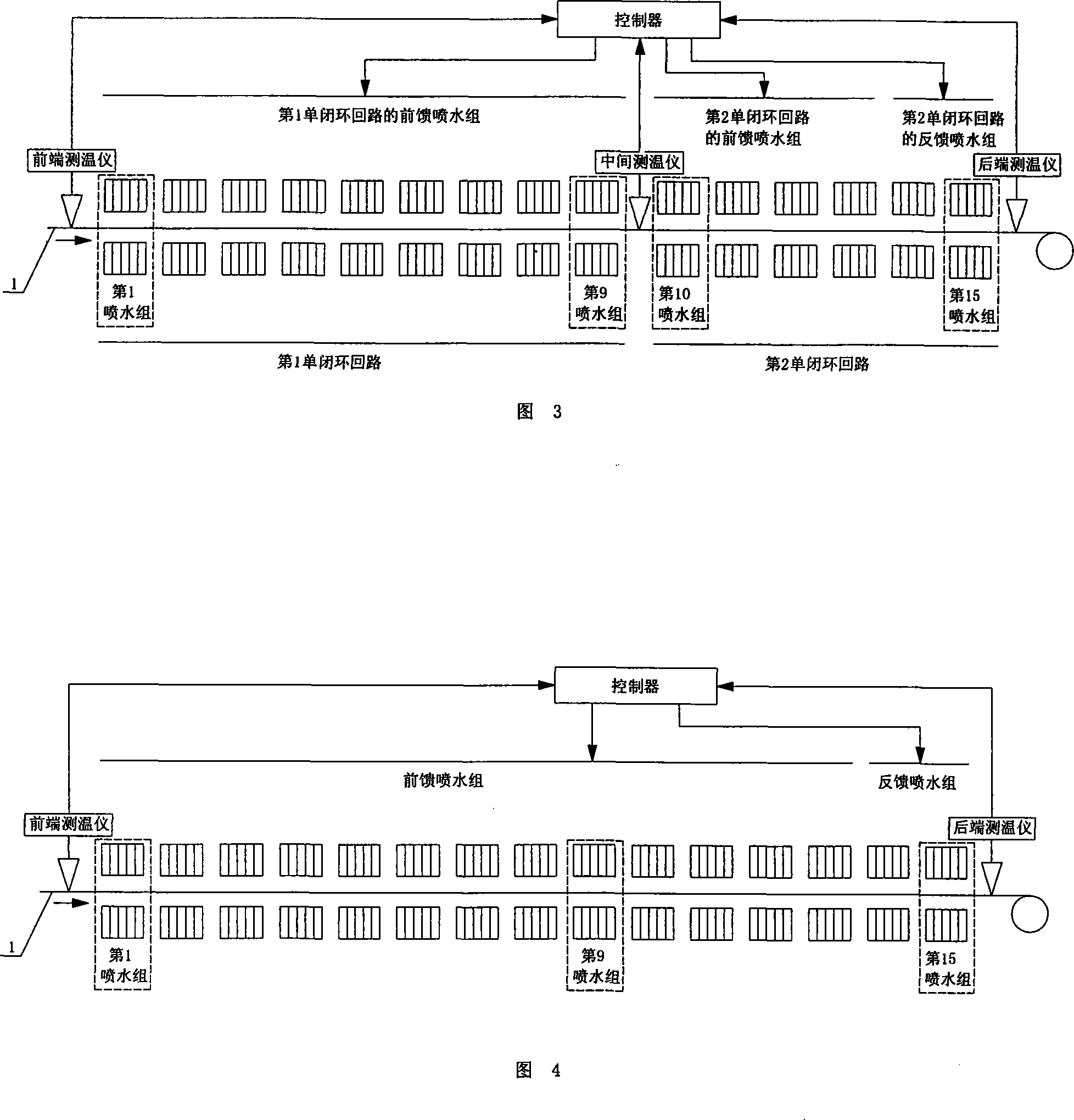

[0024] The hot-rolled strip double-loop control laminar flow cooling system includes: water spray groups arranged above and below the steel strip 1 along the output roller table (the 1st to 15th water spray groups are arranged in sequence along the running direction of the steel belt on the output roller table), It is used to control the controller of each water spray group, the front-end thermometer and the rear-end thermometer respectively arranged at the front and rear ends of the water spray group, and the system also includes an intermediate thermometer arranged between the front and rear-end thermometers; The thermometer is a thermometer for testing the temperature of the steel strip, and the output end of the thermometer is connected to the controller; the middle thermometer is set between the 9th water spraying group and the 10th water spraying group.

[0025] The control loop of the system is divided into the first single closed-loop loop and the second single closed-l...

Embodiment 2

[0030] This system is basically the same as Embodiment 1 of the present invention, except that the water spray groups in the first single closed-loop circuit are all the first single closed-loop circuit feedforward section water spray groups; The controller of the water spraying group in the feedforward section of the single closed-loop loop. At the same time, the controller is also used to control the water spraying group in the feedforward section of the second single closed-loop loop according to the data measured by the intermediate thermometer, and to control the water spraying group according to the data measured by the back-end thermometer. The controller of the water spraying group in the feedback section of the second single closed-loop loop.

[0031] Embodiments 1 and 2 of the present invention, the cooling control of the system needs to realize two target temperatures (intermediate target temperature and coiling target temperature), the cooling before the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com