High throughput preparation device for metal fibers based on multiple powder and method of preparing metal fibers by means of same

A metal fiber and preparation device technology, which is applied in the direction of improving process efficiency, additive manufacturing, and improving energy efficiency, can solve the problems of low continuity, limitation, and high cost, and achieve uniform heating, small temperature difference, and high temperature control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

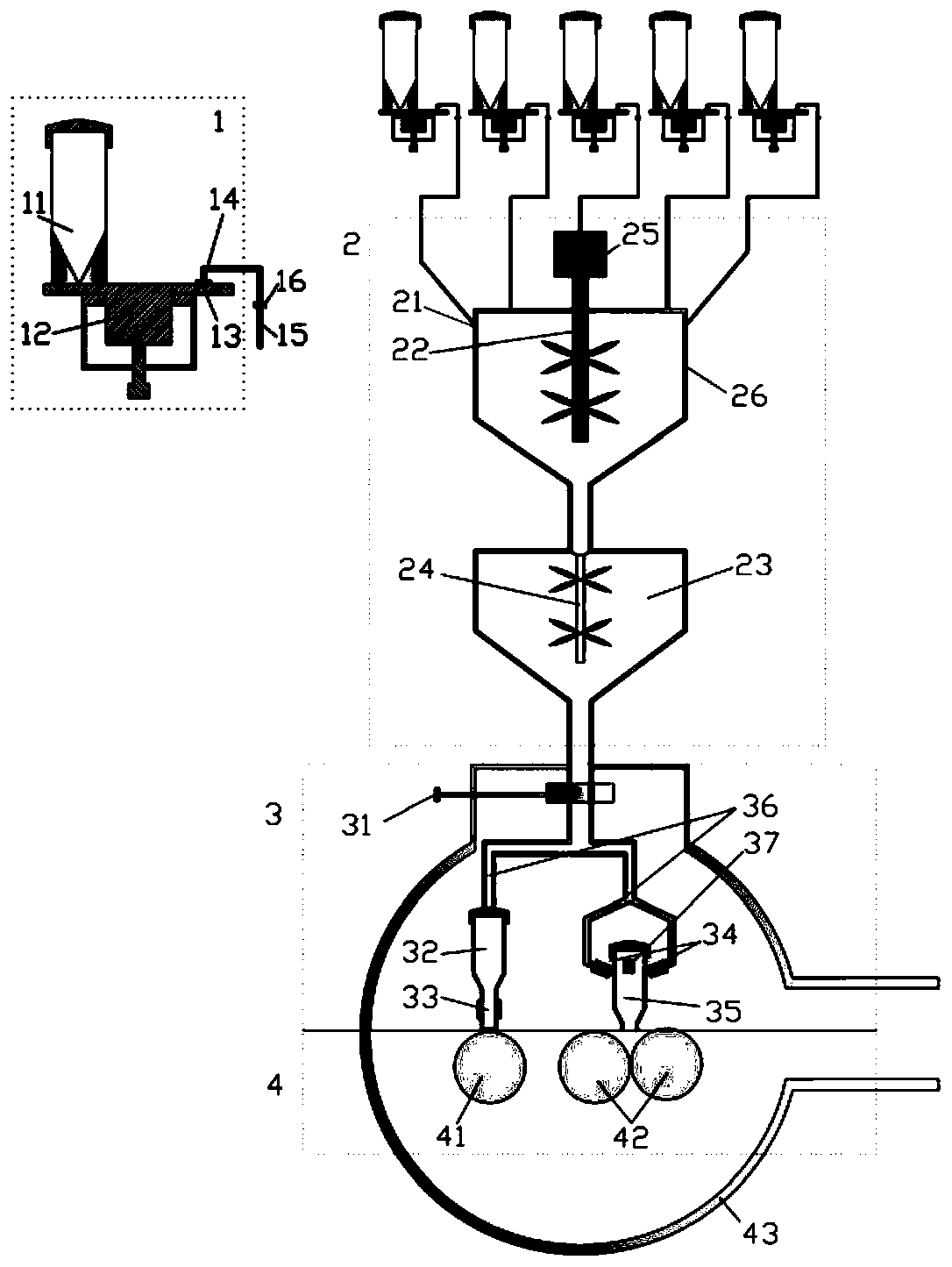

[0077] This embodiment provides a high-throughput preparation device for metal fibers based on multi-powder, such as figure 1 As shown, the pneumatic motor 12 is connected to the powder feeding disc 13, and the powder cylinder 11 stands above the powder feeding disc 13. Through the rotation of the powder feeding disc 13, the metal powder in the powder tube 11 can be sent to the powder outlet 14, and the The powder inlet 14 and the powder inlet 21 are connected through the powder feeding pipe 15, and a mass flow controller 16 is installed on the powder feeding pipe 15; The inside of the powder mixer 26 is connected with the motor 25, the powder mixer 26 and the powder storage device 23 are connected up and down, and the inside of the powder storage device 23 is provided with a static mixer 24; the powder delivery pipe 36 is connected to the powder mixer 26, and is provided with a melting The powder switching device 31 can transport the uniformly mixed metal powder to the powder...

Embodiment 2

[0081] This embodiment provides a high-throughput preparation device for metal fibers based on multi-powder, such as figure 1 Shown, the difference of described device compared with embodiment 1 is:

[0082] The included angle between the laser beam emitted by the laser 37 and the central axis at the entrance of the powder delivery pipe 36 wound with the induction preheating coil 34 is 60 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com