EH47 crack arrest steel for large container ship and manufacture method thereof

A container ship and manufacturing method technology, applied in the field of iron and steel metallurgy, can solve the problems of not being able to fully meet the crack arrest performance requirements of EH47 steel for high strength and high impact toughness, not being able to prove the crack arrest performance of steel plates, and not being scientific and rigorous. , to achieve the effects of refining grains, inhibiting grain growth, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

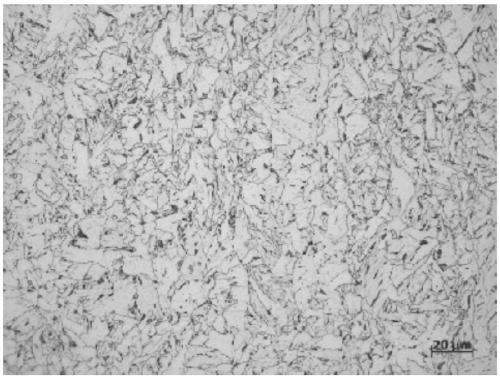

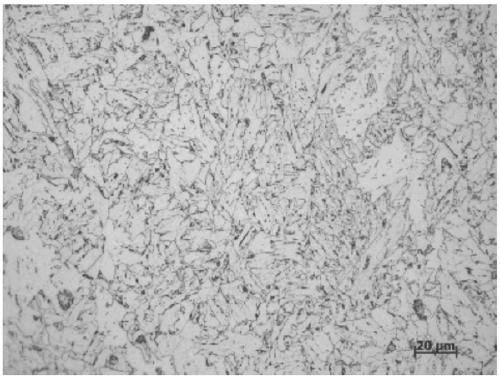

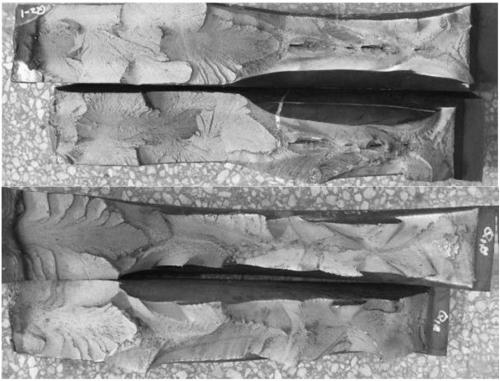

[0042] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0043] The chemical composition of the EH47 crack arrest steel for large container ships corresponding to the various embodiments of the present invention is shown in Table 1. The data in the table are the mass percentage contents of each element, and the remainder are Fe and inevitable impurity elements. 2 corresponds to the heat number S11702048, and Examples 3 and 4 correspond to the heat number S11702049.

[0044] Table 1

[0045]

[0046] Manufacturing process of steel plate:

[0047] Smelting and continuous casting process: Calculate the raw materials according to the chemical composition. The smelting raw materials are pretreated by KR molten iron and deeply desulfurized to make the sulfur content less than 0.0020%. Blow argon gas for 20 minutes, carry out RH refining, LF refining, and RH refining: RH vacuum is maintained for more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com