Hydrogen/Oxygen Fuel Generator

a hydrogen/oxygen fuel generator and hydrogen gas technology, applied in the field of methods and systems for generating oxygen and hydrogen gas, can solve the problems of their relative complexity and relatively high equipment and energy costs, the direct hazards of human safety, and the use of toxic materials, and the relative complexity of their relative cost in terms of equipment and energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

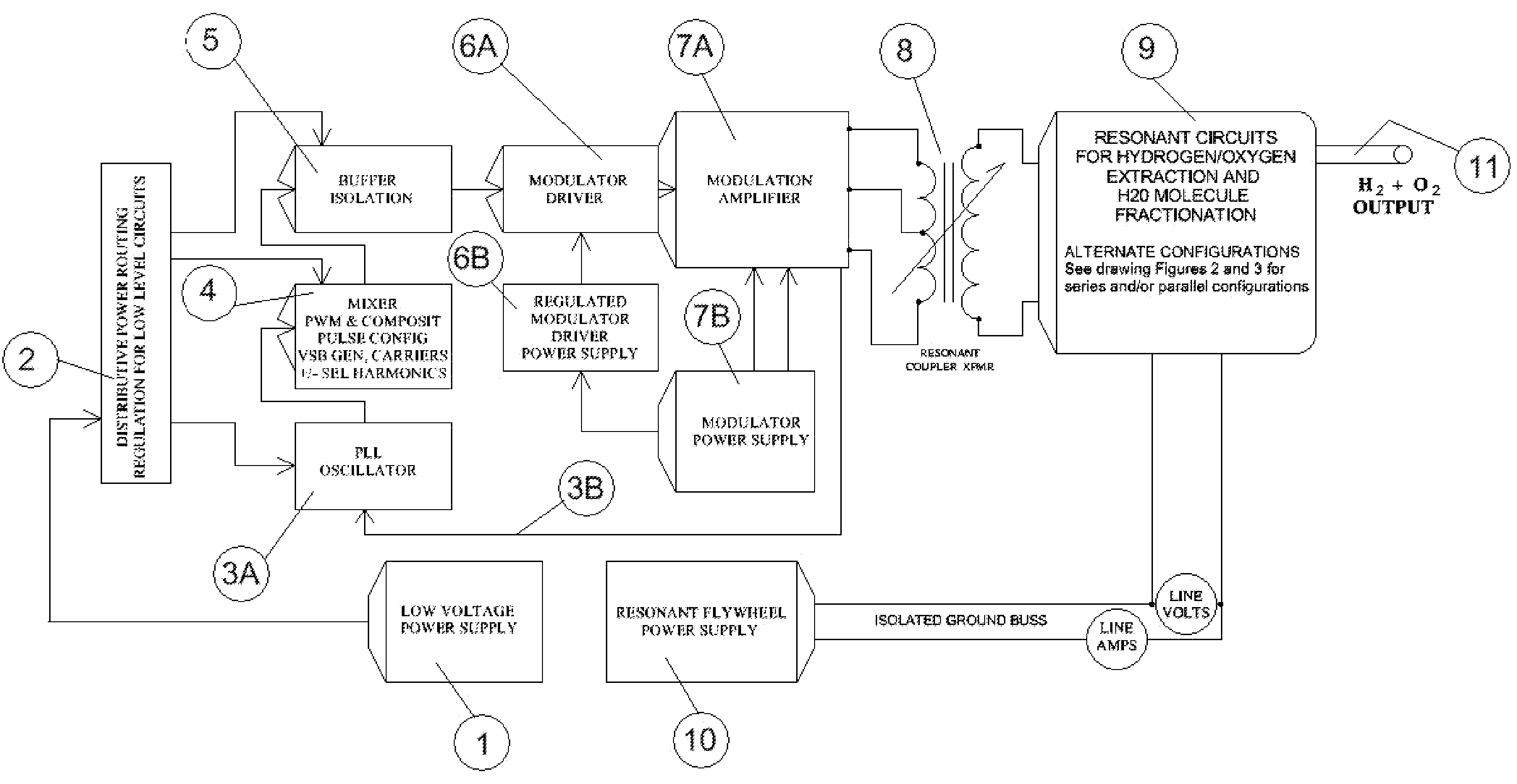

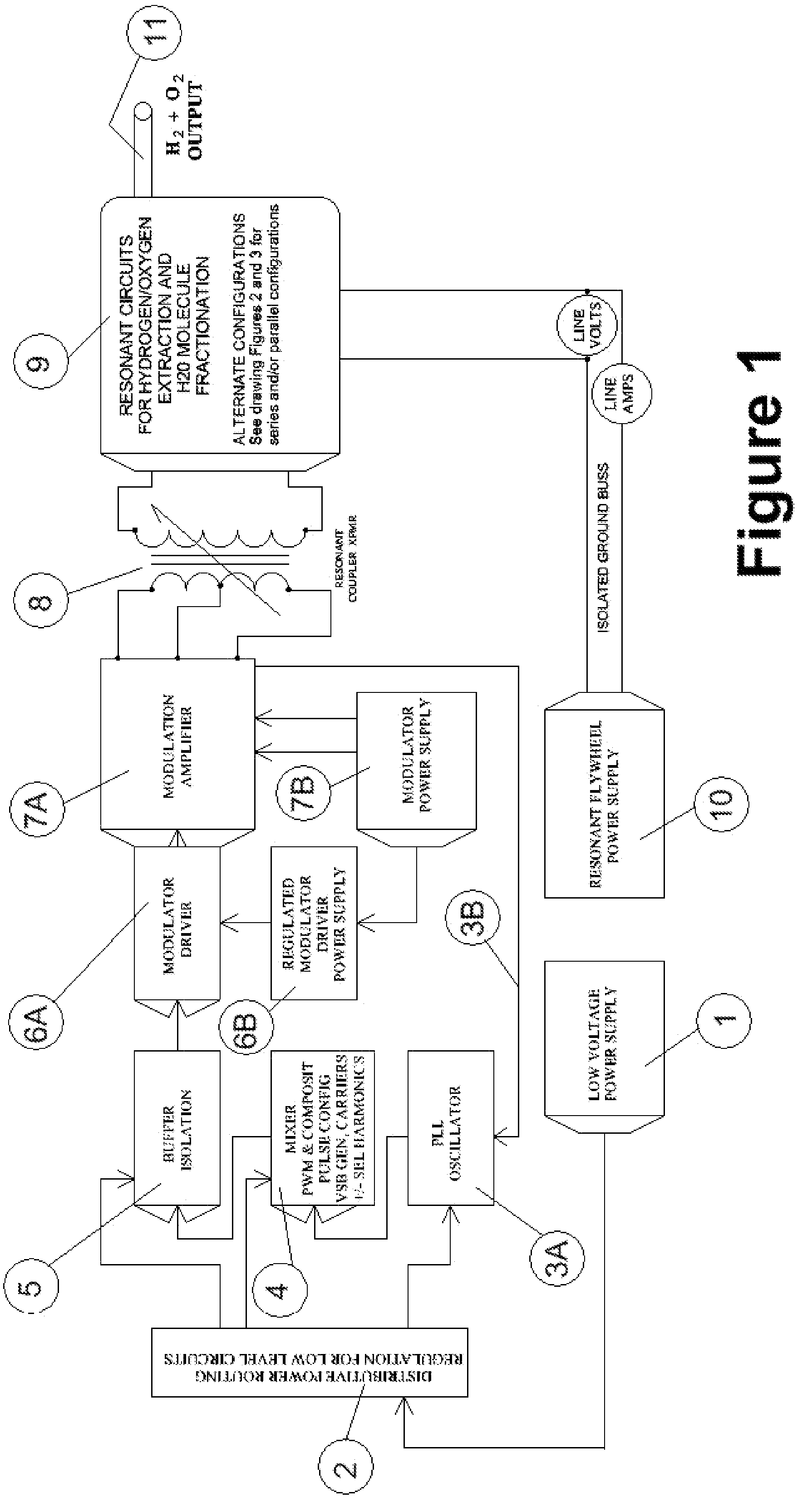

[0029]FIG. 1 is detailed as follows:

[0030]1—LOW VOLTAGE POWER SUPPLY—Delivers>80% dynamic / clamped voltage regulation to the low-level system stages with a negative chassis return.

[0031]2—DISTRIBUTED POWER SUPPLY—Provides branch low level positively regulated voltages to the low level / low current stages with >80% branch voltage regulation parameters.

[0032]3A—PLL OSCILLATOR—This stage is a PLL Oscillator, which generates three specific fundamental frequencies, the fundamental frequency, and two offset generated carriers at −18 degree carrier lags which are configured as a VSB (Vestigial Side Band). This VSB component is phase lock looped by a feed back circuit from the output modulator to the oscillator to effect frequency correction of the system.

[0033]3B—PLL—Feedback loop pulse / signal, which corrects the system operational frequency within 0.05% @67 deg F. ambient temperature as a design center.

[0034]4—PWM GENERATOR—(Pulse Wave Modulated) square wave signal with a variable duty cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com