Wide-power water electrolysis hydrogen production system and method

A hydrogen production system and electrolyzed water technology, applied in the electrolysis process, electrolysis components, separation methods, etc., can solve problems such as insufficient response capability, limited power adjustable range, and decreased gas purity, so as to reduce complexity and cost, broaden the Power operating range, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

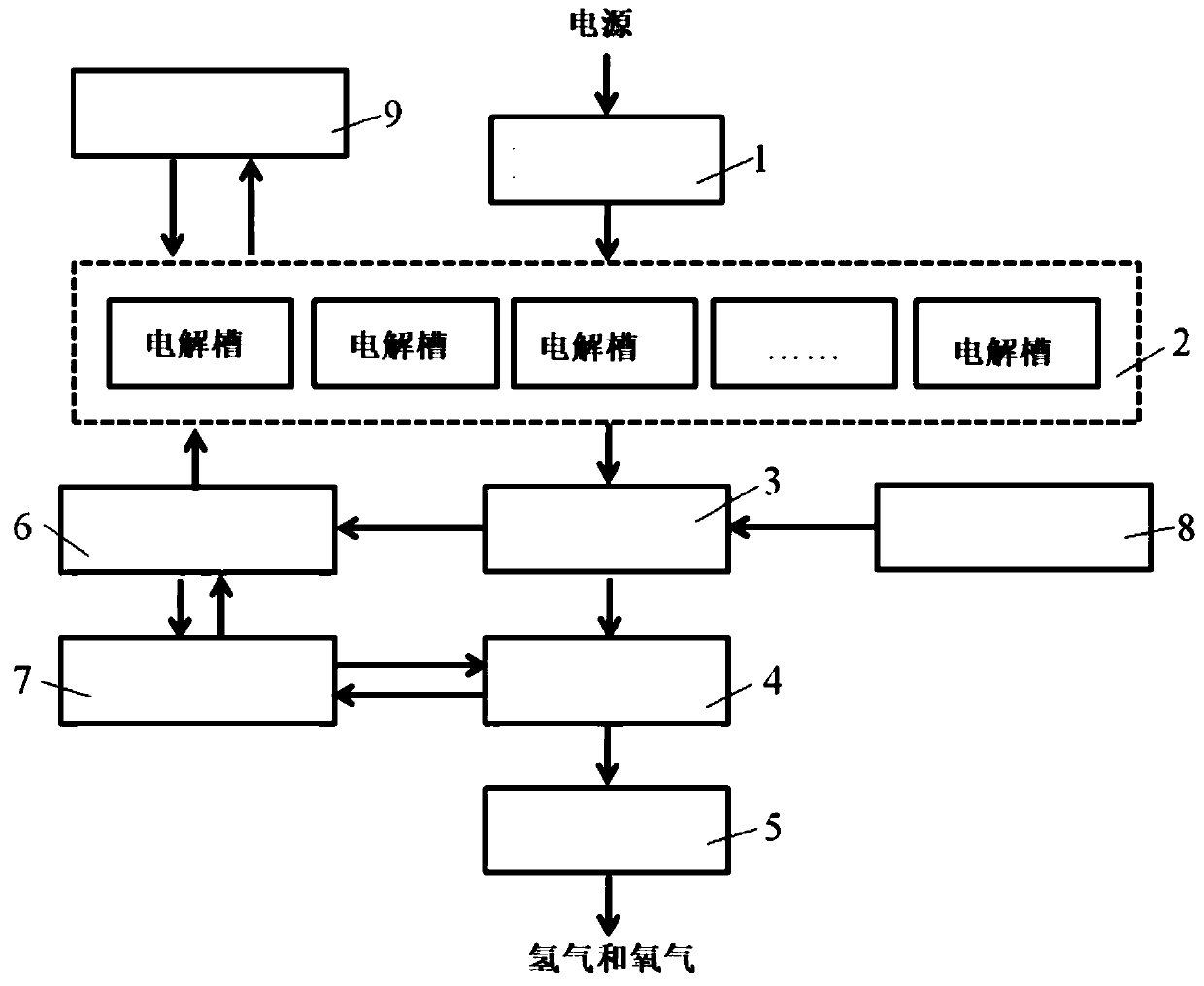

[0039] like figure 1 As shown, a wide-power electrolysis water hydrogen production system includes a rectifier transformer 1 and an electrolyzer 2. The rectifier transformer 1 converts alternating current into direct current and then passes it into the electrolyzer 2. It also includes a gas-liquid separator 3 and a gas cooler 4. , gas drop catcher 5, rectifier transformer 1 is connected with fluctuating power supply, fluctuating power supply includes wind power or photovoltaic, gas-liquid separator 3 includes hydrogen separator and oxygen separator, gas cooler 4 includes hydrogen cooler and oxygen cooler , the gas drop catcher 5 includes a hydrogen drop catcher and an oxygen drop catcher, the catholyte liquid outlet of the electrolytic cell 2 communicates with the hydrogen separator of the gas-liquid separator 3, and the anolyte liquid outlet of the electrolytic cell 2 The oxygen separator of the gas-liquid separator 3 communicates with each other, the gas outlet of the hydrog...

Embodiment 1

[0042] When the present invention is in operation, wind power or photovoltaic is used as a power source and converted into direct current that can be used for electrolyzing water through the rectifier transformer 1. The electrolyzer 2 uses an alkaline electrolyzed water electrolyzer, and the total hydrogen production scale is 1000Nm 3 / h, using two electrolyzers connected in parallel, the hydrogen production scale of each electrolyzer is 500Nm 3 / h, the minimum hydrogen production capacity of each electrolyzer is 200Nm 3 / h, the electrolyzer controller 9 determines the output of the electrolyzer according to the output of wind power or photovoltaic: when the required hydrogen production reaches 1000Nm 3 / h, both electrolyzers 2 are running at full power, and the electrolytic solution flowing out of the cathodes of the two electrolyzers 2 is merged into the hydrogen separator of the gas-liquid separator 3, and the hydrogen gas enters the gas cooler 4 after escaping from the hyd...

Embodiment 2

[0044] like figure 1 As shown, wind power or photovoltaic is used as a power source and converted into direct current for electrolysis of water through rectifier transformer 1, and electrolysis cell 2 uses an alkaline electrolysis water electrolysis cell, with a total hydrogen production scale of 1000Nm 3 / h, using two electrolyzers connected in parallel, the hydrogen production scale of each electrolyzer is 500Nm 3 / h, the minimum hydrogen production capacity of each electrolyzer is 200Nm 3 / h, the electrolyzer controller 9 determines the output of the electrolyzer according to the output of wind power and photovoltaic: when the required hydrogen production reaches 200Nm 3 / h, one electrolyzer 2 stops running, and the other electrolyzer 2 produces hydrogen with an output of 200Nm 3 / h, the electrolytic cell 2 that stops running, the electrolyte no longer circulates, and at the same time, the electrolytic current is adjusted to zero, and in the electrolytic cell 2 that is ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com