Test device and method for detecting security of fuel battery passenger car hydrogen feed system

A fuel cell and safety technology, used in measuring devices, machine/structural component testing, instruments, etc., can solve the problem of damage to fuel cells, failure to correctly evaluate the performance of the hydrogen supply system for fuel cell buses, and hydrogen supply for fuel cell buses. System security comprehensive testing and other issues to achieve the effect of improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

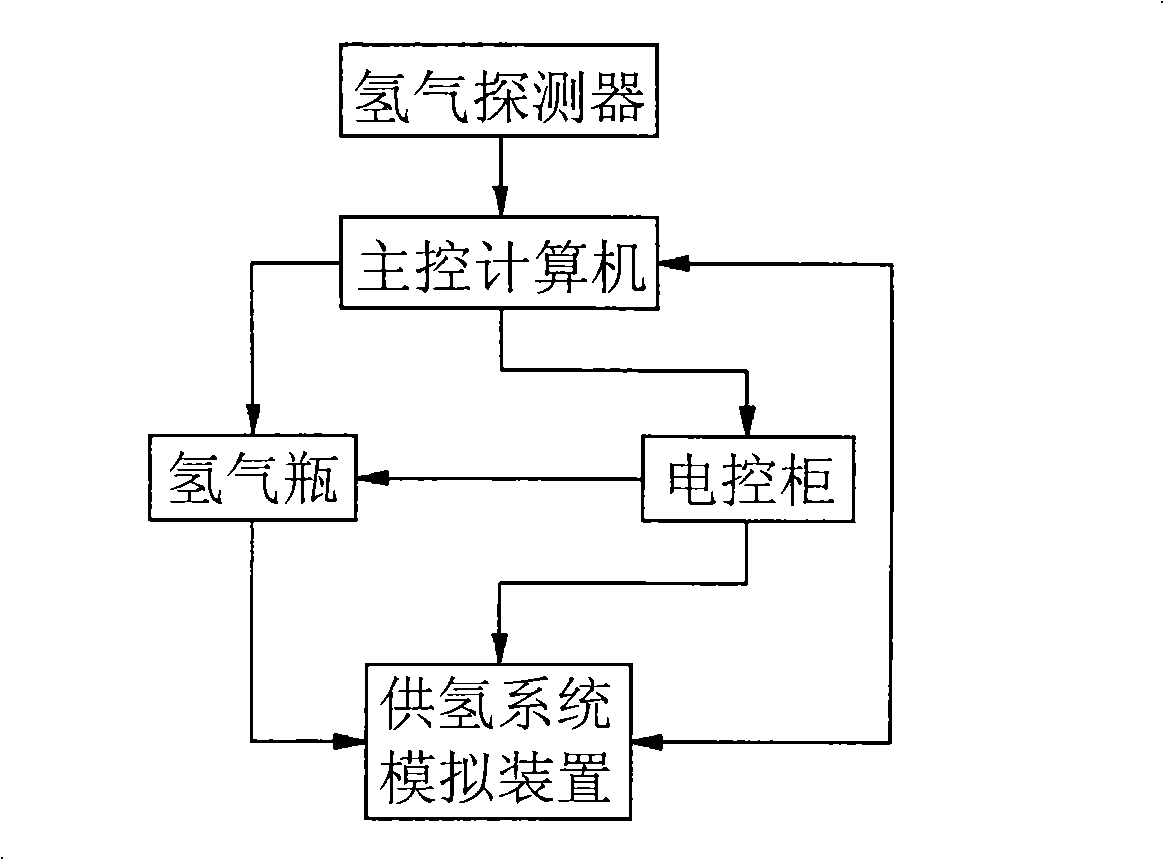

[0019] The composition of the test bench of the present invention is as follows: figure 1 As shown, it includes a hydrogen supply system simulation device, a main control computer, an electric control cabinet, a high-pressure hydrogen gas cylinder, and a hydrogen gas detector; wherein, the hydrogen supply system simulation device is connected to the output port of the high-pressure hydrogen gas cylinder, and is bidirectionally connected to the main control computer; The main control computer is connected with the electric control cabinet, the high-pressure hydrogen cylinder, and the hydrogen tank, and the electric control cabinet is connected with the high-pressure hydrogen cylinder and the hydrogen supply system simulation device respectively; the test bench also includes a stand for fixing and supporting the hydrogen supply system simulation device . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com