Hydrogenation method for medium and low temperature coal tar

A low-temperature coal tar and hydrocracking technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve problems such as poor product quality, achieve light weight, optimize raw materials, and prolong the operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

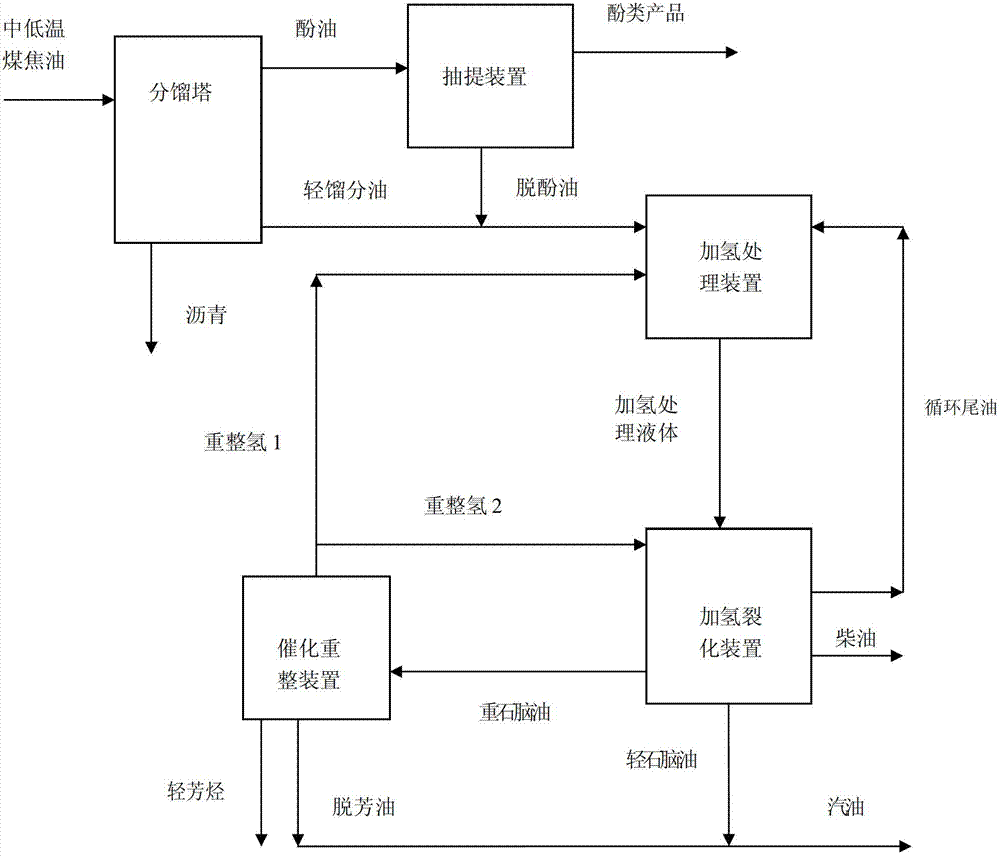

[0028] The specific method of the present invention is as follows: after the pretreatment of the medium and low temperature coal char raw materials, carry out fractionation in a fractionation tower to obtain phenol oil, light distillate oil and asphalt, wherein the phenol oil is subjected to dephenol treatment to obtain phenol products and dephenol oil , the light distillate oil obtained by fractionation, dephenolized oil and hydrogen are mixed into the hydrotreating reaction zone, the liquid produced by hydrotreating enters the hydrocracking reaction zone, the liquid produced by hydrocracking enters the product fractionation tower, and the middle distillate obtained by fractionation is used as For clean diesel products, the tail oil obtained by fractionation is recycled back to the hydrocracking reaction zone or hydrotreating reaction zone, the naphtha obtained by fractionation enters the catalytic reforming reaction zone, and the hydrogen obtained by catalytic reforming is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com