Two-stage hydrocracking method for increasing yield of middle distillate oil

A technology for middle distillate and hydrocracking, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of high operating cost, high catalyst cracking activity, increase operating cost, etc., and achieve simple and good operation. Anti-NH3 and H2S performance, the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

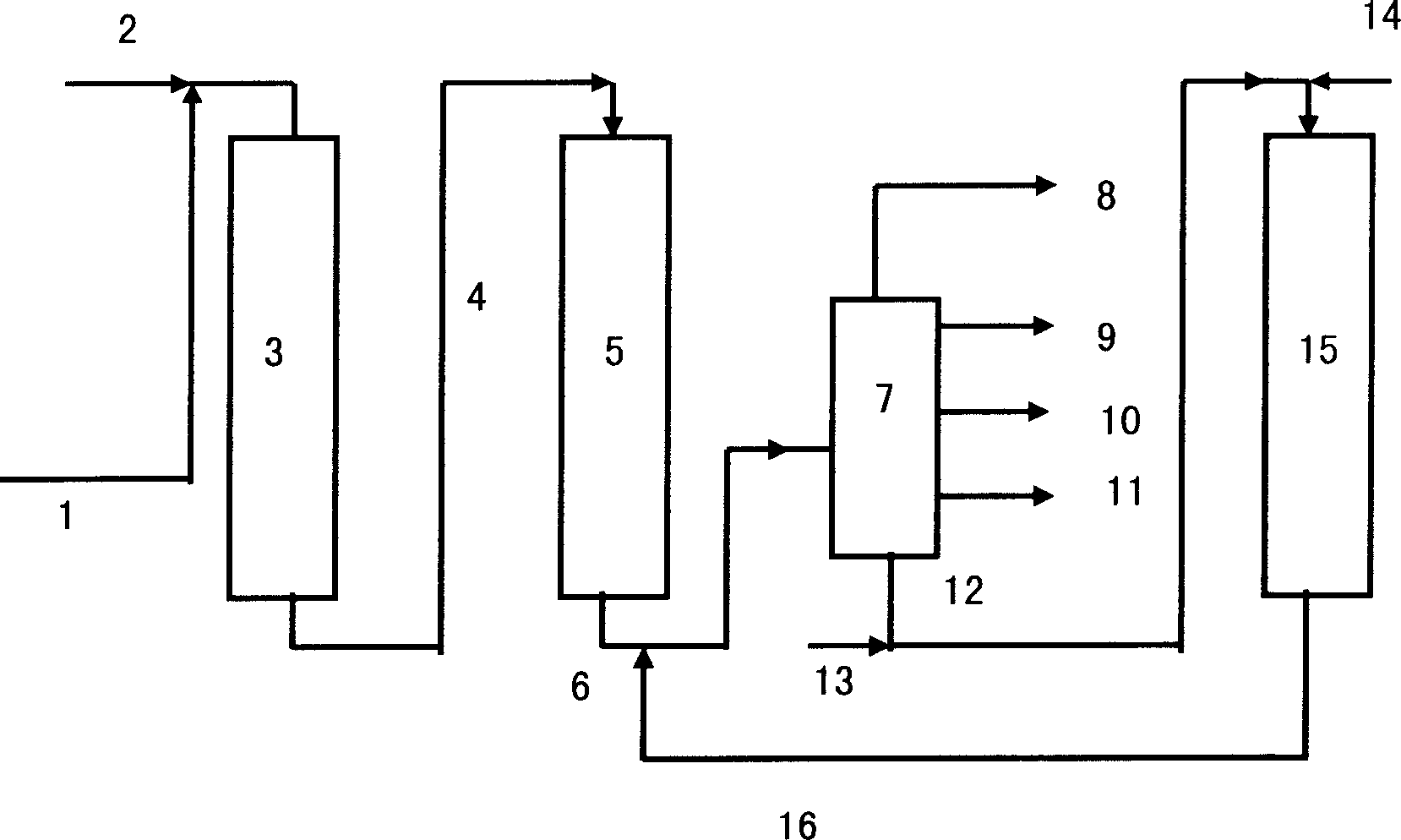

Image

Examples

Embodiment 1

[0032] Embodiment 1 is to mix 2% fresh raw material oil in the comparative example circulating oil, embodiment 2 is to mix 5% fresh raw material oil in the comparative example circulating oil, embodiment 3 is to mix 10% fresh raw material oil in the comparative example circulating oil . It can be seen that under the same process conditions, the yield of middle distillates increases, the hydrogen consumption decreases, and high-quality middle distillates can still be produced after blending fresh feedstock oil into circulating oil.

[0033] It can be seen that, under the premise of ensuring the quality of the middle distillate, the present invention can achieve the purpose of increasing the production of the middle distillate, reducing the hydrogen consumption, and expanding the processing capacity of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com