Hydrogen heat exchanger for a hydrogen filling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

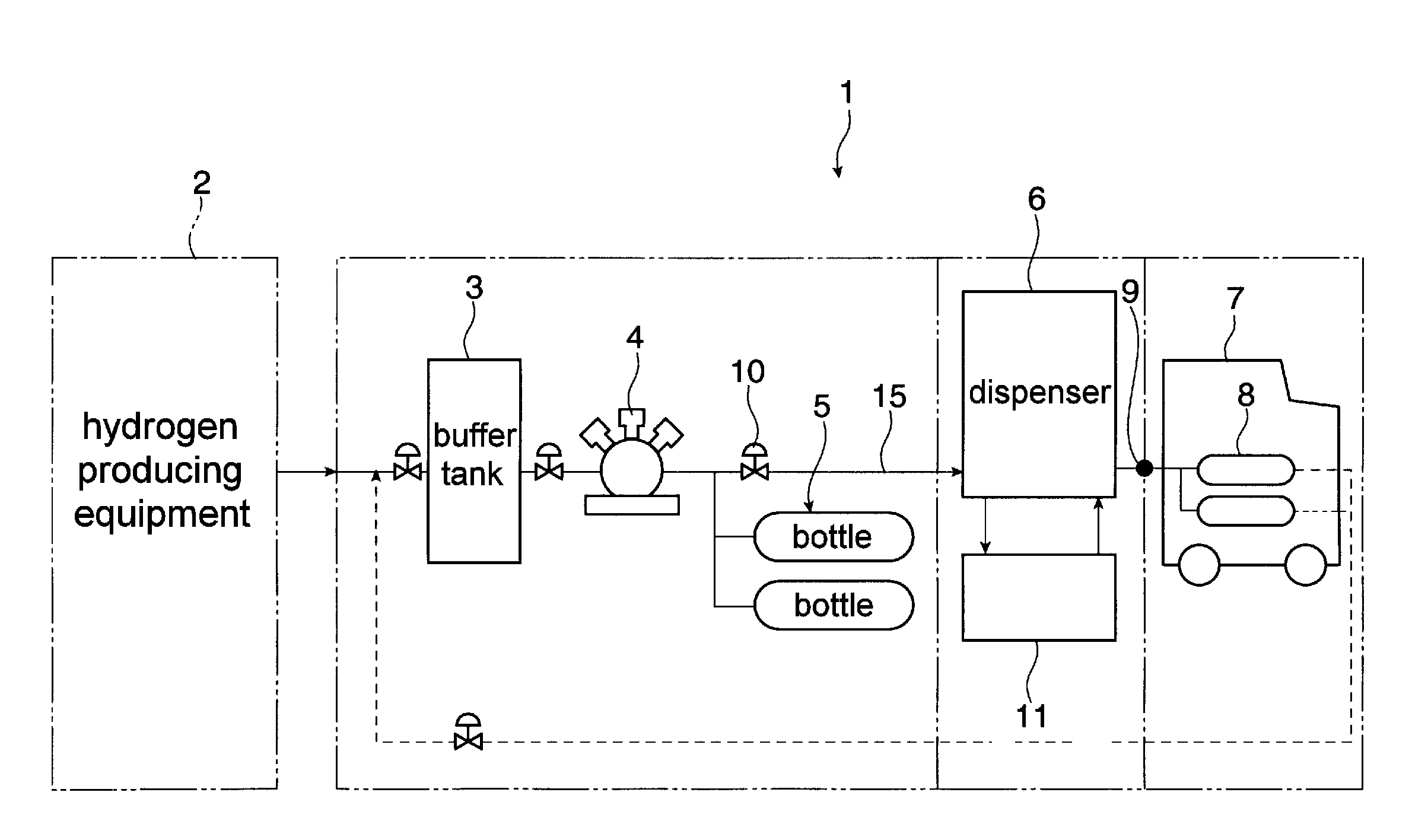

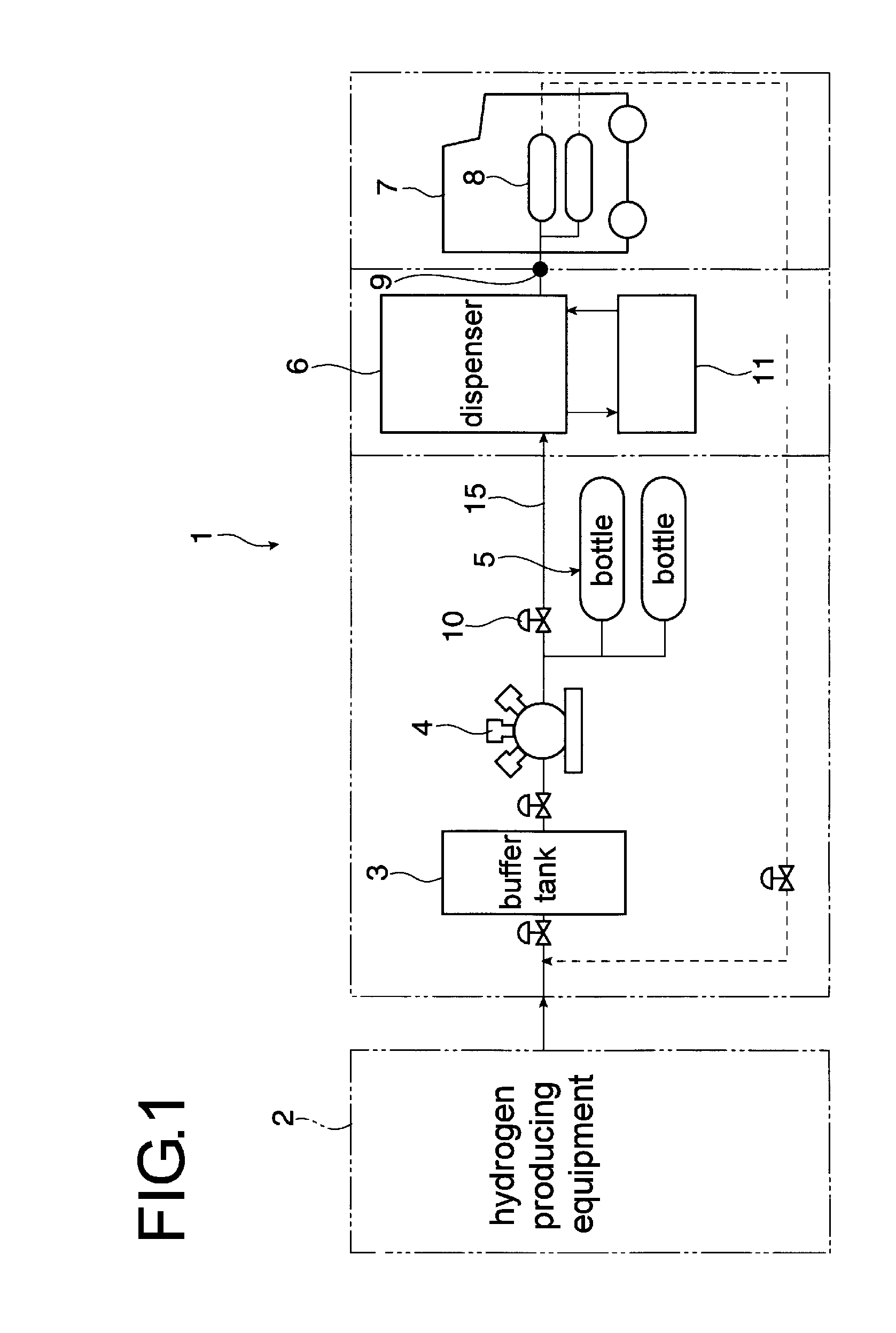

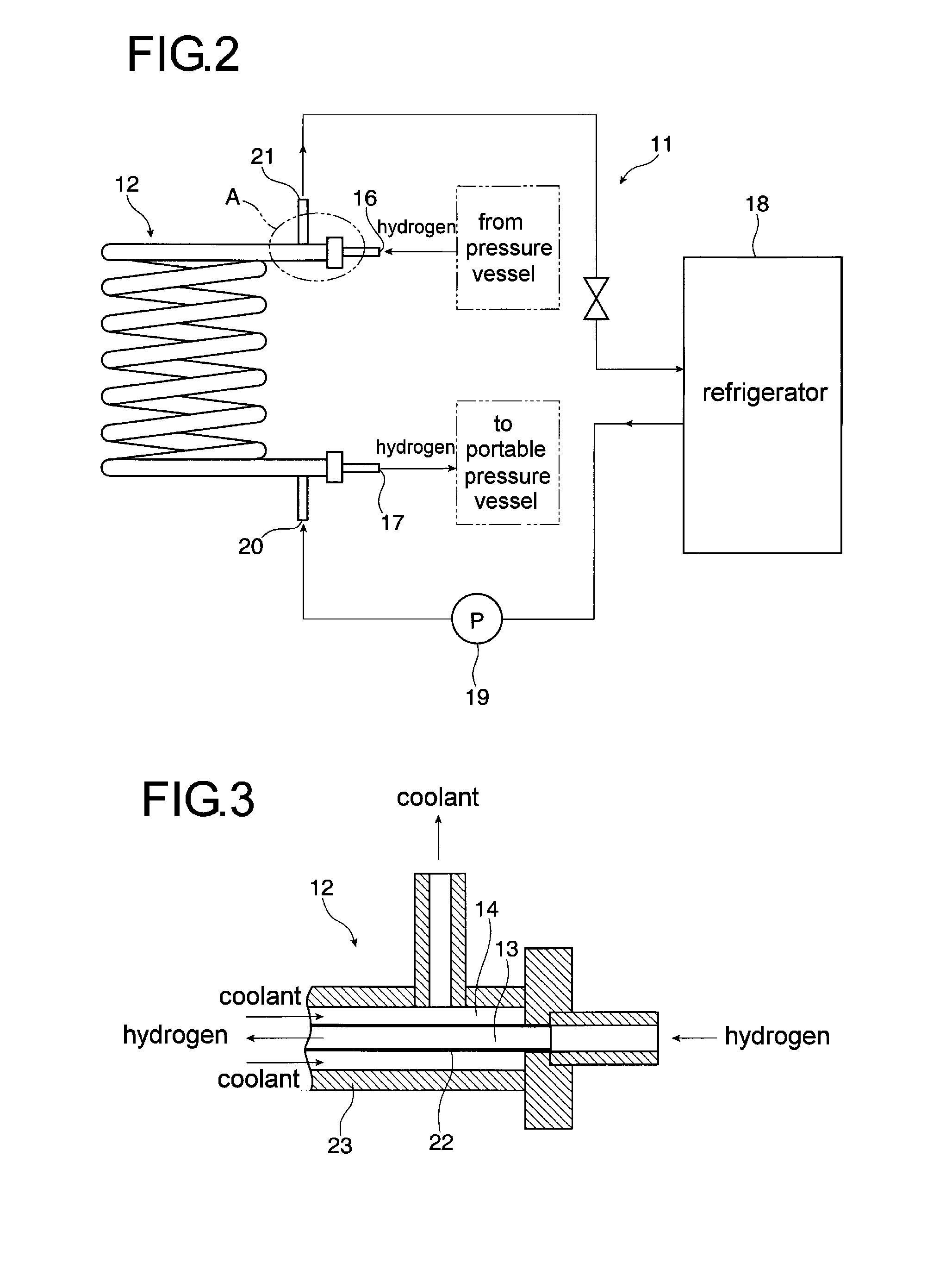

[0043]Embodiments of the present invention will be explained referring to figures below. FIG. 1 is a view of a constitution showing summary of a hydrogen filling system 1 embodiment. Hydrogen is produced with a known hydrogen producing equipment 2 and stored in a buffer tank 3 as a hydrogen storing tank. The hydrogen in this buffer tank 3 is supplied to a compressor 4 through piping, valves or the like and compressed with this compressor 4 to get high pressure. The hydrogen compressed to high pressure is stored in a hydraulic accumulator 5. The accumulator 5 consists of plurality of bottles and necessitated quantity of hydrogen can be taken out continuously through switching the valves of the these bottles sequentially. The hydrogen volume and pressure within each bottle, flow rate of hydrogen or the like are displayed on the display (not shown) provided in the hydrogen filling system.

[0044]In an ordinary manner, hydrogen produced with the hydrogen producing equipment 2 is transport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com