Fuel cell hydrogen and air supply control method, device and system

An air supply and fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of frequent fluctuations in the pressure difference of the proton exchange membrane, affecting the performance and life of the fuel cell, and the inability to adjust hydrogen and air pressure differences. Effects of accurate adjustment, reduction of creep, durability and running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

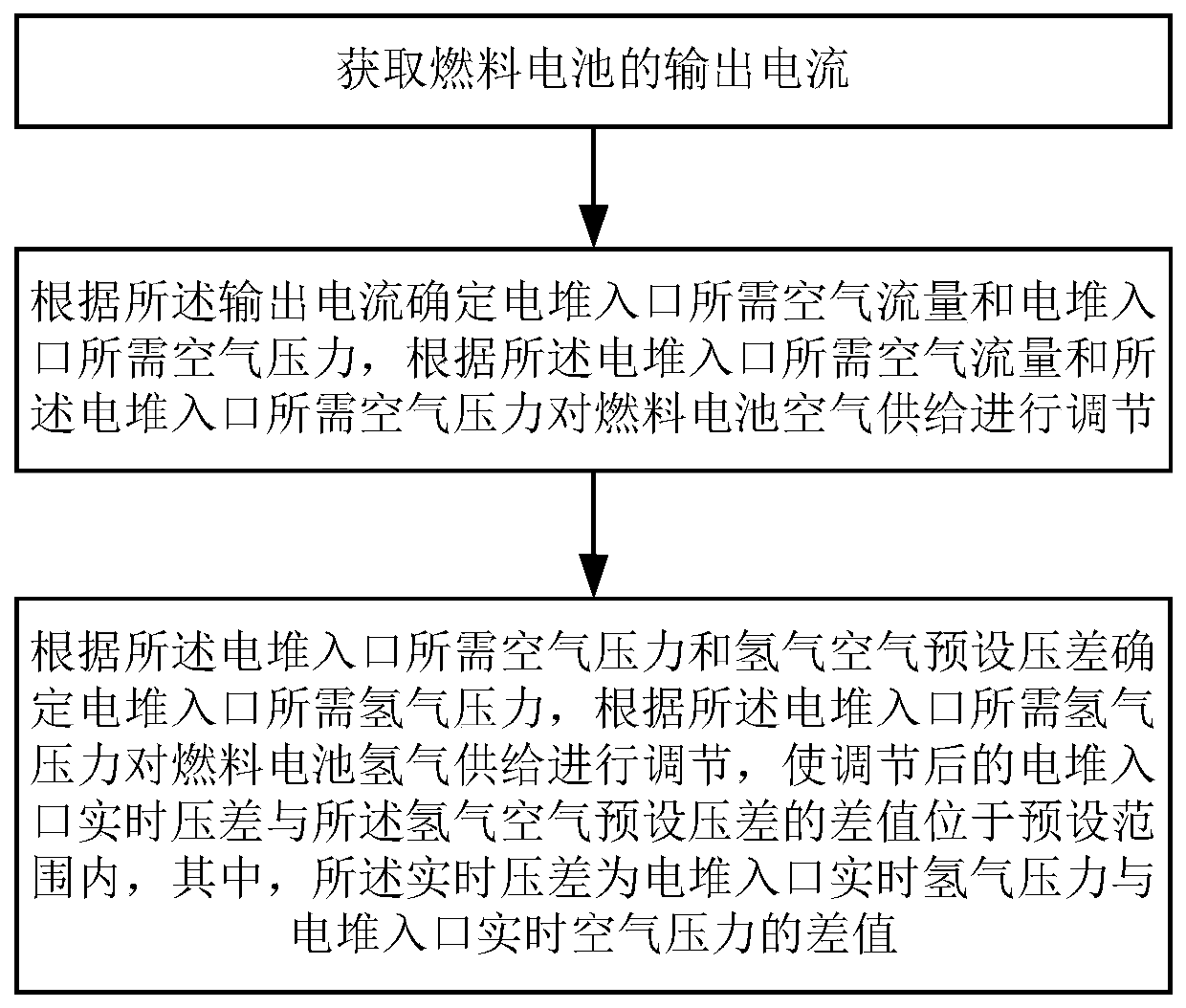

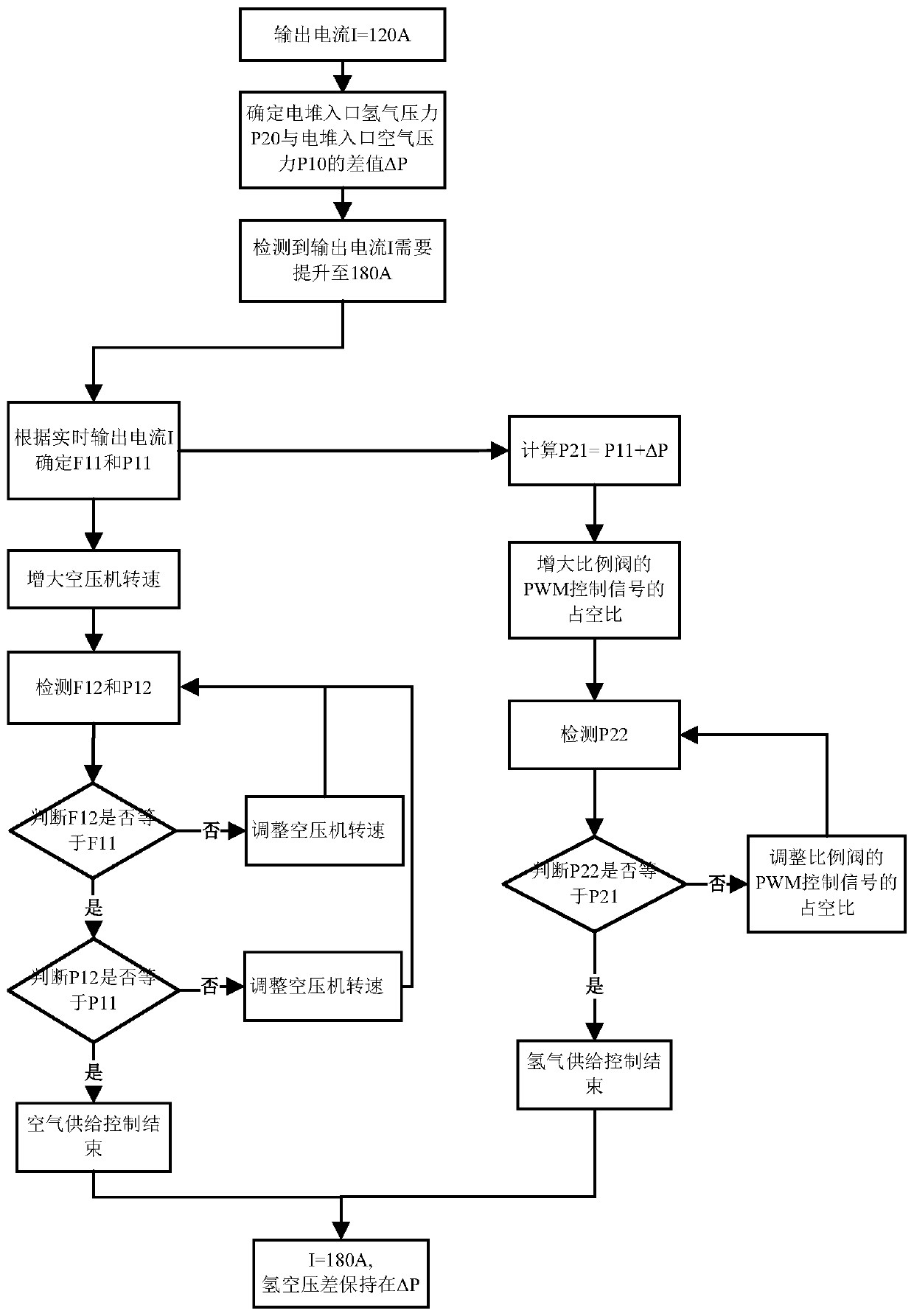

[0031] When the fuel cell is running, the hydrogen pressure and air pressure are required to increase with the increase of the output current, so as to ensure that the performance of the stack is always in the best state. When the current is low, the hydrogen pressure and air pressure in the stack are relatively small, and when the current is high, the hydrogen pressure and air pressure in the stack are relatively high. However, in order to ensure the characteristics of the proton exchange membrane, it is necessary to ensure that the hydrogen-air pressure difference is basically a fixed value. At the same time, the required hydrogen flow rate and the air flow rate of the stack also increase with the increase of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com