Process for preparing composite carbon carrier noble metal dehydrogenation catalyst

A technology of dehydrogenation catalyst and composite carbon, which is applied in the direction of refining to remove heteroatoms, etc., can solve the problems that the physical structure such as pore structure and pore size distribution has not been studied, and achieve improved anti-coking performance, improved dehydrogenation activity, and stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (1). Preparation of composite carbon carrier and suitable process conditions

[0046]The operating factors affecting the preparation of composite carbon support include: reaction temperature, reaction time, hydrocarbon gas concentration and nitrogen flow rate. Through multiple experimental studies on the above operational factors, the order of influence of the operational factors obtained by means of the orthogonal test method is: reaction temperature>reaction time>nitrogen flow rate>hydrocarbon gas concentration.

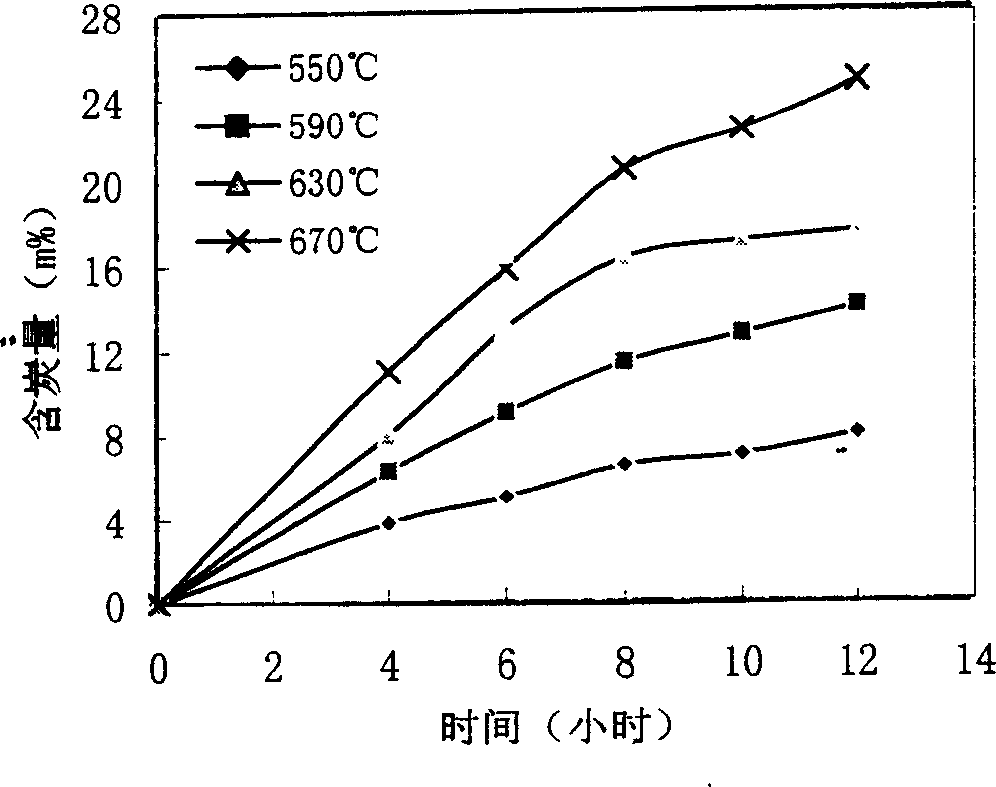

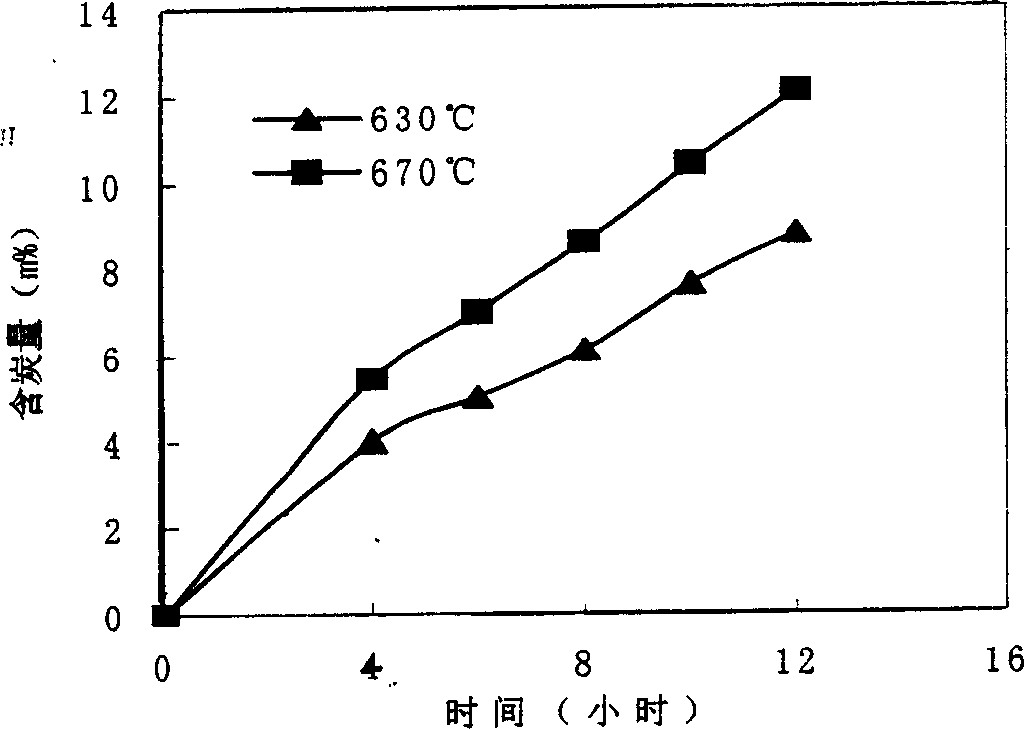

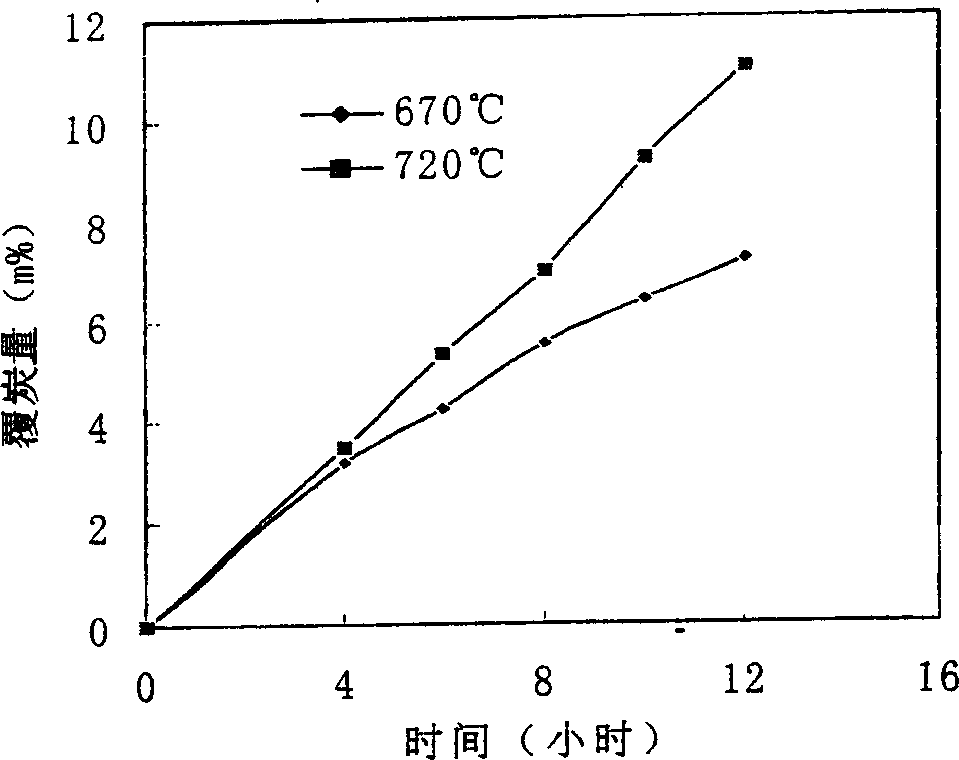

[0047] 1. Effect of reaction temperature and reaction time on carbon content of composite carbon carrier

[0048] In order to investigate the influence of reaction temperature and reaction time on the carbon content, firstly, the olefin type compound hydrocarbon A was used as the raw material, and the composite char The relationship between the carbon content of the carrier and the reaction time. Test results such as figure 1 Shown:

[0049] from figure...

Embodiment 1

[0125] 1. Preparation of composite carbon carrier, refer to attached figure 1 , put the solid inorganic material (aluminum oxide) in the reactor, and place the raw material hydrocarbon A cyclohexene in the vaporizer, N 2 After the gas is dried, it enters the vaporizer, and the cyclohexene is brought into the reactor. The cyclohexene is cracked at a high temperature of 800°C, and the carbon substances generated by the cracking are combined with the solid inorganic material alumina. After 14 hours, the product containing A composite carbon carrier with a carbon content of 34%. After the reaction, the tail gas is discharged into the atmosphere.

[0126] 2. Catalyst preparation: First, measure the water absorption of CCS, and then prepare a certain concentration of H according to the water absorption and metering ratio 2 PtCl 6 and SnCl 2 Mix the solution, adjust the pH value of the solution to be acidic, and immerse the CCS in the mixed solution for 24 hours. After natural a...

Embodiment 2

[0132] 1. Preparation of composite carbon carrier, refer to attached figure 1 , the solid inorganic material alumina is placed in the reactor, and the raw material hydrocarbon A cyclohexene is placed in the vaporizer, N 2 After the gas is dried, it enters the vaporizer, and the hydrocarbon A cyclohexene is brought into the reactor. The hydrocarbon is cracked at a high temperature of 600°C. The carbon-like substances generated by the cracking are combined with the solid inorganic material alumina, and the carbon-containing material can be obtained after 10 hours. 30% composite carbon carrier. After the reaction, the tail gas is discharged into the atmosphere.

[0133] 2. Catalyst preparation: First, measure the water absorption of CCS, and then prepare a certain concentration of H according to the water absorption and metering ratio 2 PtCl 6 and SnCl 2 Mix the solution, adjust the pH value of the solution to be acidic, and immerse the CCS in the mixed solution for 24 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com