Method of improving total coke rate of heat recovery coke oven

A technology of heat recovery and full coking rate, which is applied in the field of coking, can solve the problems of difficult control of coking temperature, out-of-control coking of coke cake surface layer, increased coking of coke cake, etc. The effect of high output of single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

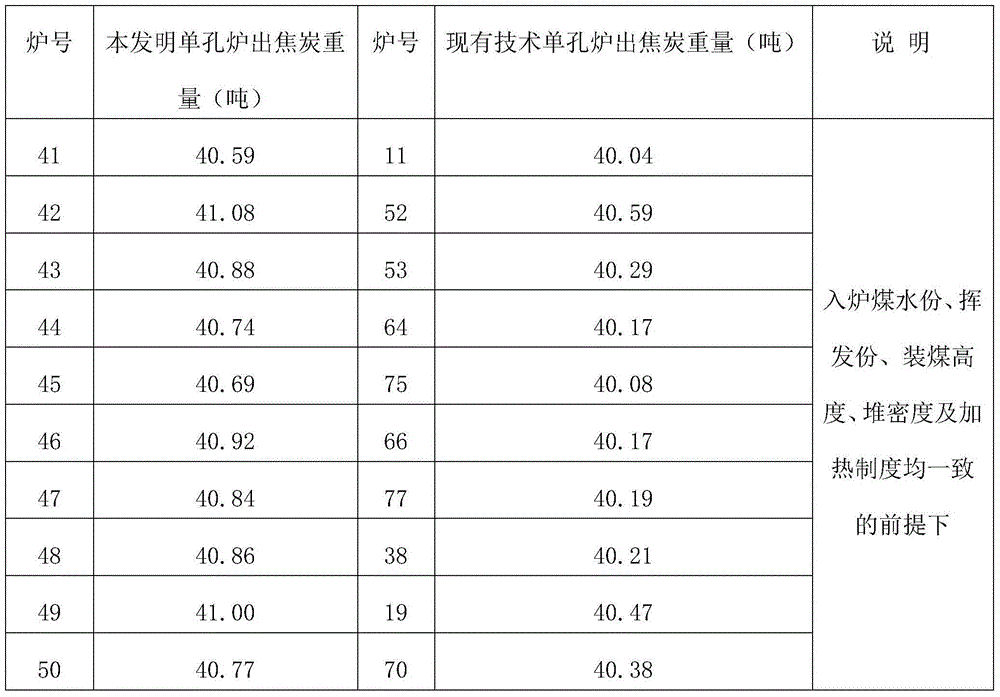

Examples

Embodiment Construction

[0015] A method for improving the total coke rate of a heat recovery coke oven in this embodiment comprises the following steps:

[0016] 1) Set 4 primary air inlets on the roof of the heat recovery coke oven, respectively marked as 1#, 2#, 3# and 4#, and set the air inlet opening dials next to the 4 primary air inlets for passing through The air inlet cover quantitatively controls the air intake. The dial is evenly divided into 6 equal parts and marked with 6 / 6, 5 / 6, 4 / 6, 3 / 6, 2 / 6, 1 / 6 and 0 scales, of which 6 / 6 means the primary air inlet is fully open, 0 means the primary air inlet is fully closed;

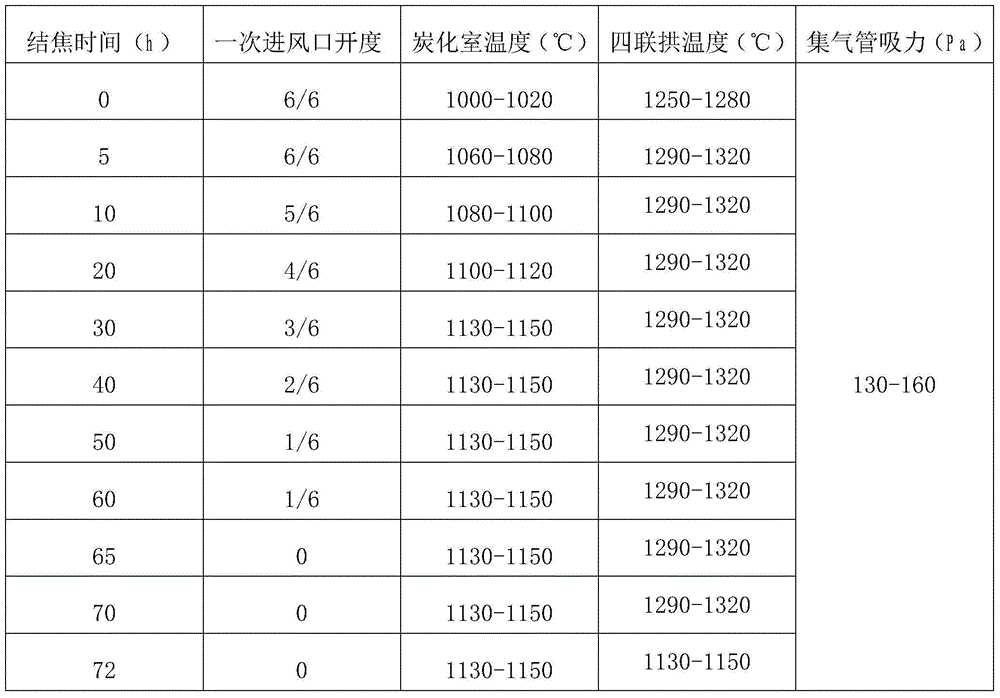

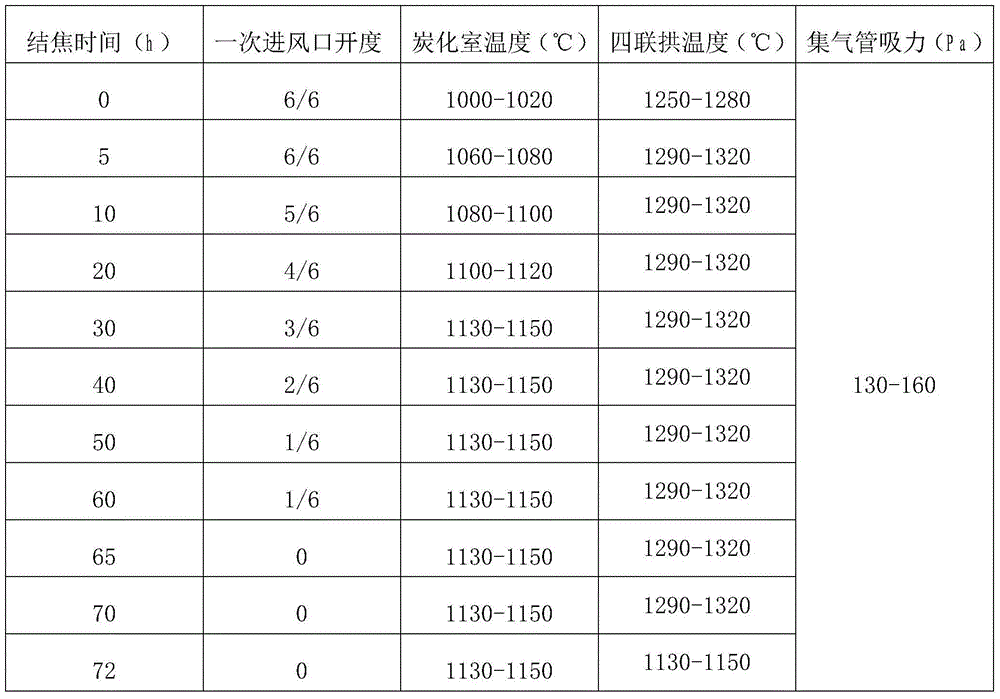

[0017] 2) After loading the briquettes into the carbonization chamber of the heat recovery coke oven, set the openings of the four primary air inlets on the top of the heat recovery coke oven to full open state, and adjust the opening of the primary air inlets according to the coking time, Simultaneously adjust the temperature of the carbonization chamber of the heat recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com